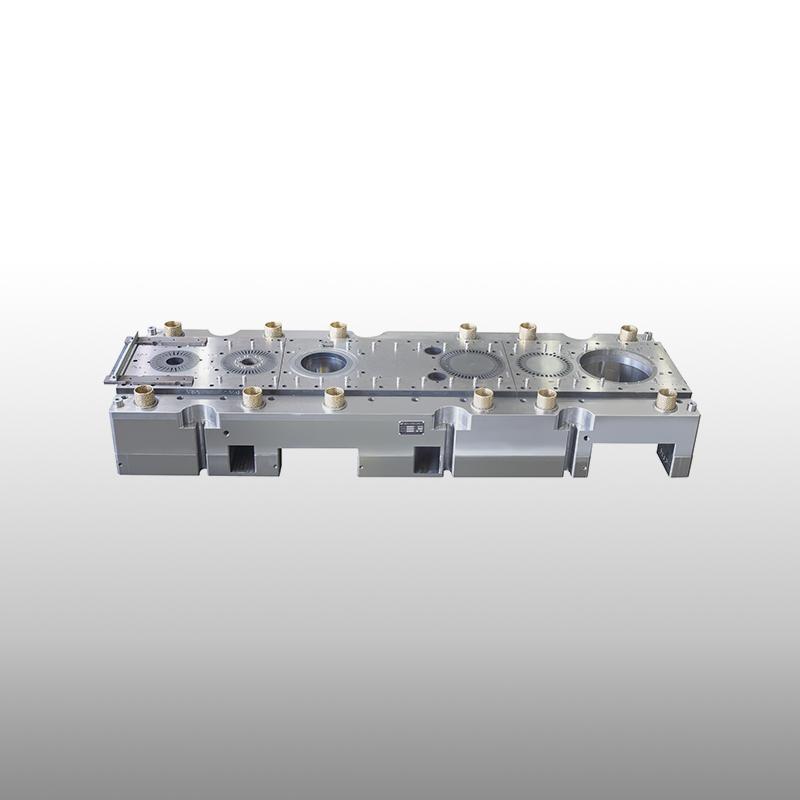

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Поиск

Категории

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Больше

Automotive Steering System Market Outlook and In-Depth Study of Top Key Players: Insights by Fact MR

The automotive steering system market has experienced significant growth, driven by...

Pain Management Devices Market Outlook and Investment Potential by 2025-2032

Pain Management Devices Market is poised to grow from USD 18.83 Billion in 2024 to USD 89.55...

Key Players Shape Antifreeze Proteins Market

A revolution is silently unfolding at sub-zero temperatures, driven by a class of remarkable...

Compra Monedas FC 26 y Monedas EA FC 26: Mejora tu Equipo en FC26

Compra Monedas FC 26 y Monedas EA FC 26: Mejora tu Equipo en FC26

Si eres un apasionado de los...

3 Piece Double Breasted Suit

Navy Blue Suit Combinations That Never Fail

Your navy blue suit is your best friend on any...

© 2026 Scenario.press - libera espressione

Russian

Russian