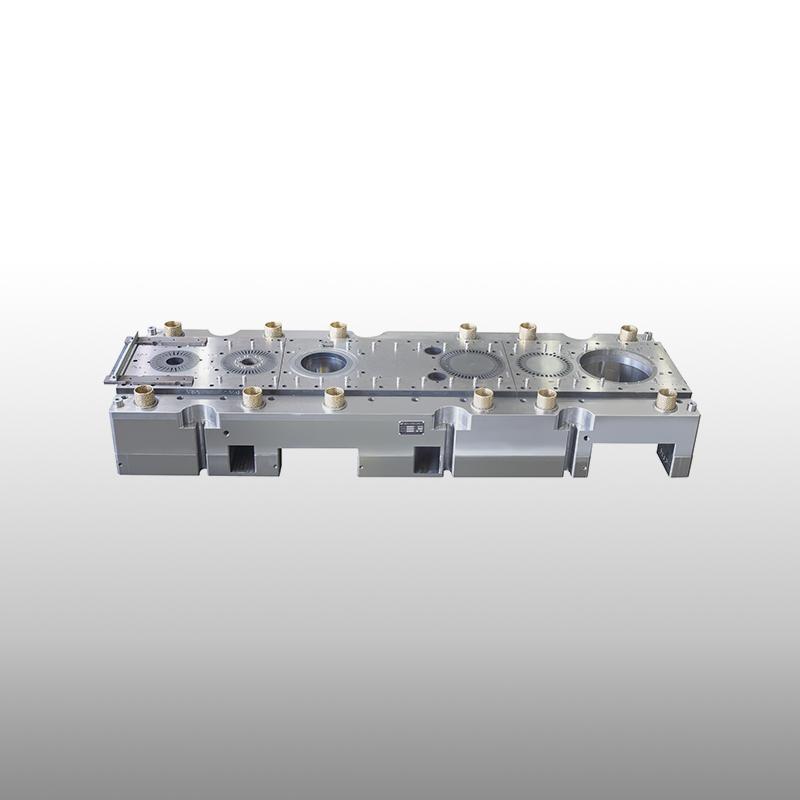

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Zoeken

Categorieën

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

A Sister’s Grace: Celebrate Bhai Dooj in Pure Paithani from House of Hind

Bhai Dooj is not just a festival—it’s an emotion that celebrates one of the most...

Mahindra Car Key Cover: A Must-Have for Every Owner

When you invest in a powerful and stylish Mahindra vehicle — whether it's the rugged...

Come Ottenere Crediti FC 25 e Crediti FIFA 25 per Massimizzare i Tuoi FIFA Coins

Come Ottenere Crediti FC 25 e Crediti FIFA 25 per Massimizzare i Tuoi FIFA Coins

Giocare a FIFA...

What Are the Key Benefits of Smart Home Remodeling in Plano?

Smart home remodeling in Plano is more than just a luxury; it’s a strategic investment that...

WotLK Wyrmrest Accord Reputation Guide

In your World of Warcraft adventure, accumulating WoW Gold becomes pivotal, especially when...

© 2025 Scenario.press - libera espressione

Dutch

Dutch