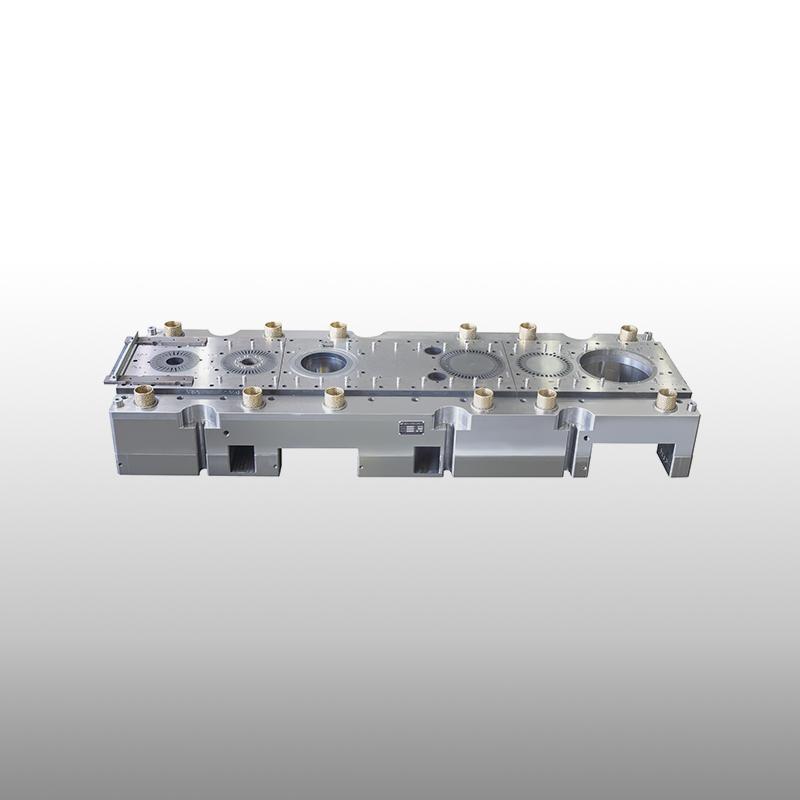

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Buscar

Categorías

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leer más

**EA FC 25 Coins Kaufen: So sichern Sie sich die besten FIFA 25 Münzen für Xbox One**

EA FC 25 Coins Kaufen: So sichern Sie sich die besten FIFA 25 Münzen für Xbox One

In...

Europe’s marine outboard engine market Germany, France, Italy, and the UK lead regional consumption.

"

Europe’s marine outboard engine market is poised for a decade of sustained, data-backed...

Unlock Your Adventure: Buy Cheap Path of Exile 2 Gold for Sale Today!

Unlock Your Adventure: Buy Cheap Path of Exile 2 Gold for Sale Today!

Path of Exile 2 transcends...

Chicago’s Top Cosmetic Surgeons | Excellence in Plastic Surgery Care

When searching for the best cosmetic surgeons in Chicago, choosing a trusted clinic is essential...

Digital Identity Solutions Market insights uncovering regional growth patterns and competitive benchmarks across industry verticals

Digital Identity Solutions Market insights uncovering regional growth patterns and competitive...

© 2026 Scenario.press - libera espressione

Spanish

Spanish