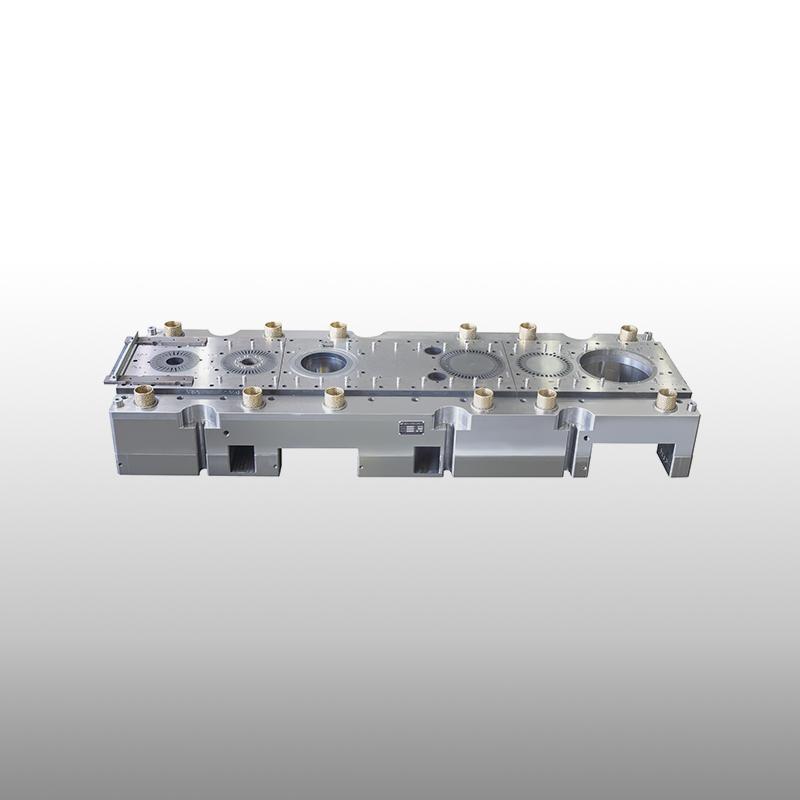

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Rechercher

Catégories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Lire la suite

The Guide of Unlocking the Tattoos in PoE 3.26

The acknowledgment of tattoos in Path of Exile 3.26, post-Ancestral Trial, has active body...

Frozen pineapple Market Size and Global Report 2032

Frozen pineapple Market Analysis 2024-2032

The Global Frozen pineapple Market report provides...

Guía Completa para Comprar Jugadores en FC 25: Precios y Estrategias

Guía Completa para Comprar Jugadores en FC 25: Precios y Estrategias

Si eres un...

Los Mejores Precios de Jugadores en FC 25: Guía Completa para Obtener los Precios de FC 25 Jugadores

Los Mejores Precios de Jugadores en FC 25: Guía Completa para Obtener los Precios de FC 25...

Best Tips to Make Your Business Profile Stand Out in Online Directories

Creating an online presence is essential for every business today. One of the most...

© 2025 Scenario.press - libera espressione

French

French