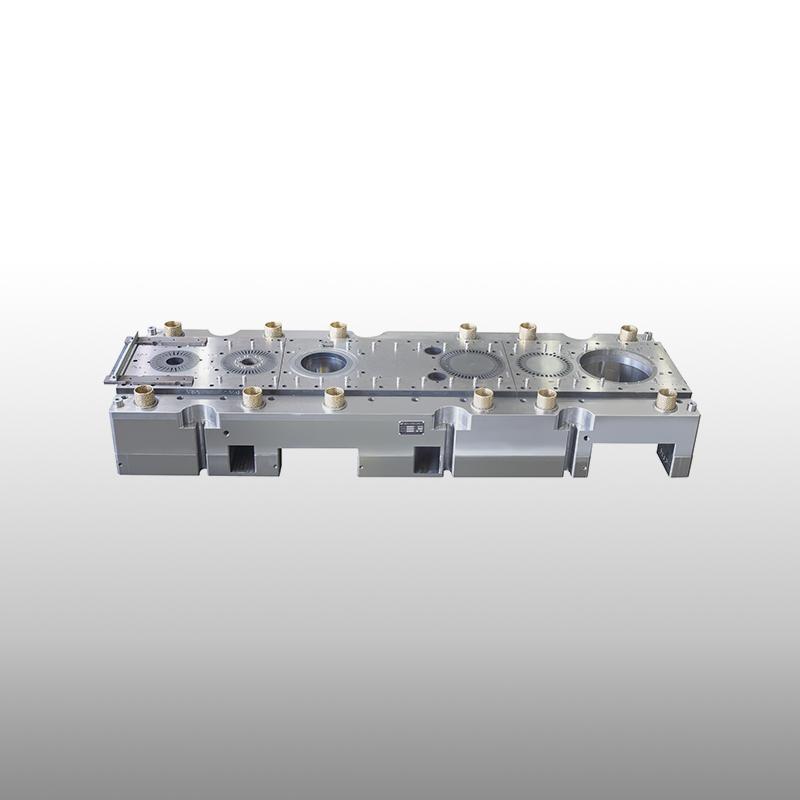

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Cerca

Categorie

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leggi di più

Micro LED Market Driving Innovation in Smart Devices, Automotive, and Wearables

The global micro LED market is poised to undergo meteoric expansion over the...

Acheter des autocollants Monopoly Go pour récompenser vos joueurs avec des cartes exclusives !

Acheter des autocollants Monopoly Go pour récompenser vos joueurs avec des cartes...

Optical Bypass Switches Market To Increase At Steady Growth Rate Till 2032

Optical Bypass Switches Market: Trends and Insights

The Optical Bypass Switches...

Global Outdoor Flooring Market Size, Share, Key Drivers, Growth Opportunities and Global Trends 2032

The global Outdoor Flooring Market is expected to reach USD 3.09 Biliion by the end of 2032,...

© 2025 Scenario.press - libera espressione

Italiano

Italiano