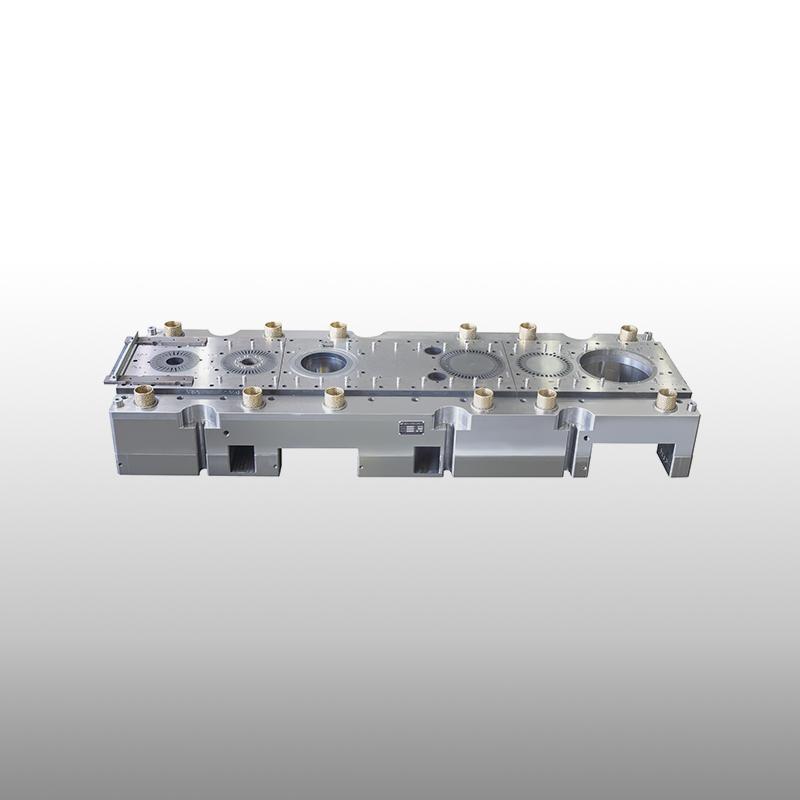

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Căutare

Categorii

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Citeste mai mult

Crafting D2: Unlocking the Power of D2 Chain of Honor in D2R – Your Guide to Buying Items

Crafting D2: Unlocking the Power of D2 Chain of Honor in D2R – Your Guide to Buying Items...

**"Guía Completa para Comprar FIFA Coins y Optimizar Tu Experiencia en FC 26: Consejos sobre Cómo Comprar Monedas FC 26 de Forma Segura y Eficiente"**

Guía Completa para Comprar FIFA Coins y Optimizar Tu Experiencia en FC 26

Si eres un...

Global ECG Patch and Holter Monitor Market 2023 - 2028: Market Trends

The Global ECG Patch and Holter Monitor Market size is valued at around USD...

Fixed-Mobile Convergence Market Size, Share | Global Report [2032]

Fixed-Mobile Convergence Market Overview:

The Fixed-Mobile Convergence (FMC) market is rapidly...

What Types of Tools Are Best for CNC Machining Titanium?

When CNC machining titanium, it's essential to use tools specifically designed for the...

© 2025 Scenario.press - libera espressione

Romaian

Romaian