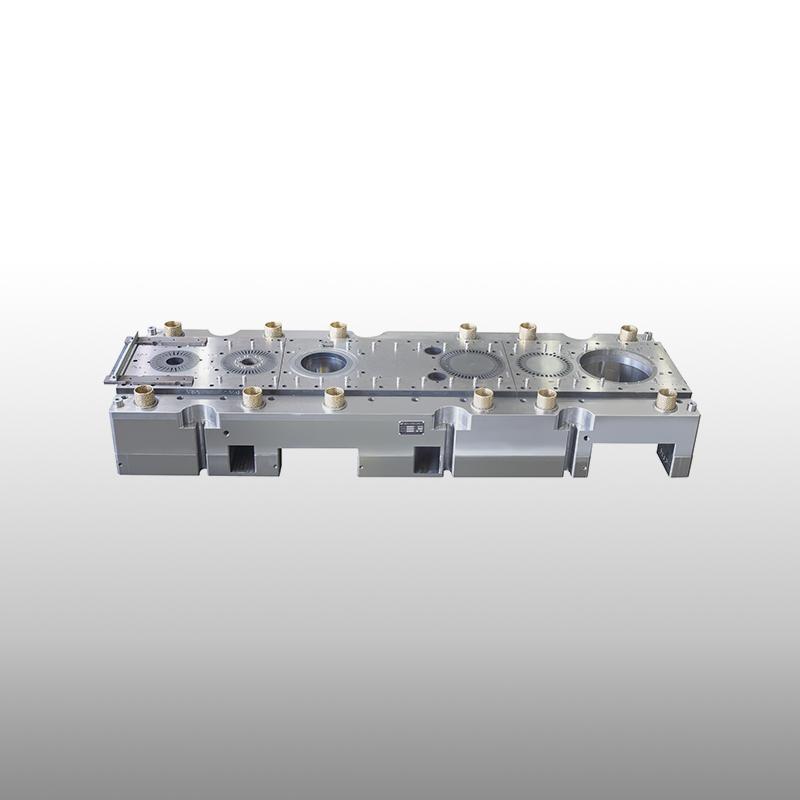

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Pesquisar

Categorias

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leia mais

Maximisez vos Avantages avec le Crédit FC25 : Tout Savoir sur les Crédits FC 25

Maximisez vos Avantages avec le Crédit FC25 : Tout Savoir sur les Crédits FC 25...

Todo Lo Que Necesitas Saber Sobre FIFA Coins: Cómo Adquirir Monedas FC26 y Monedas EA FC 26 Efectivamente

Todo Lo Que Necesitas Saber Sobre FIFA Coins: Cómo Adquirir Monedas FC26 y Monedas EA FC...

Roll Off Dumpster Service

Need a convenient way to manage heavy debris from renovations, landscaping or roofing? Our roll...

Europe DTC Lab Testing Market Expansion, Regulations & Insights

The Europe Direct-to-Consumer (DTC) Laboratory Testing Market is undergoing significant...

Ultimate Guide to Diablo 2 Unique Items and Rune Crafting: Unlocking the Best Gear and Strategies

Ultimate Guide to Diablo 2 Unique Items and Rune Crafting: Unlocking the Best Gear and Strategies...

© 2026 Scenario.press - libera espressione

Portuguese (Brazil)

Portuguese (Brazil)