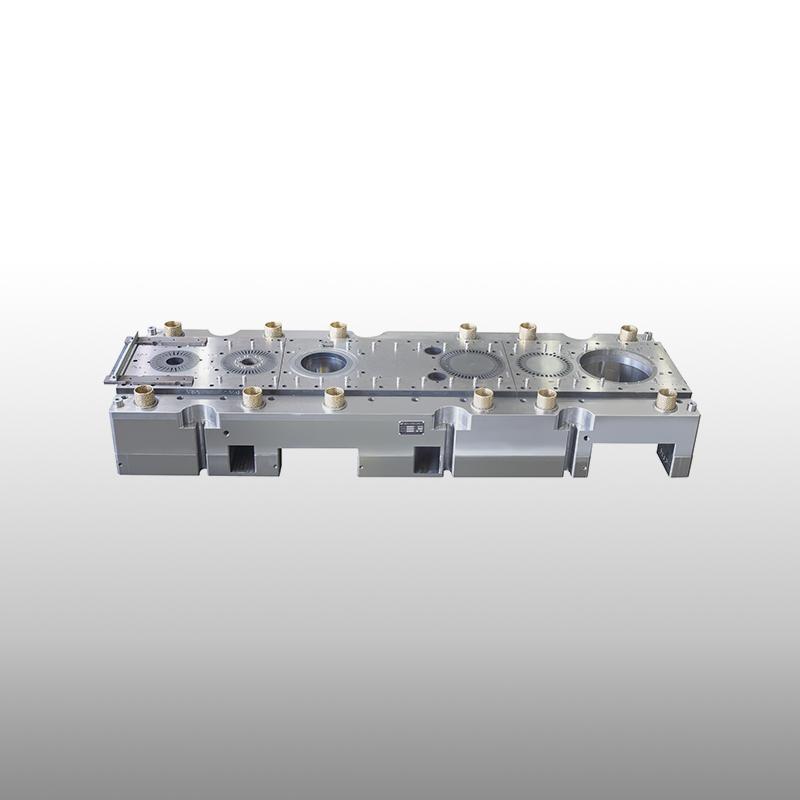

Custom Core Lamination Stamping Factory

The core lamination stamping process doesn't end with the lamination and curing stages. After the core is formed, it is typically subjected to quality control checks to ensure that it meets the specifications required for its intended application. These checks might include testing for dimensional accuracy, magnetic properties, and overall structural integrity. Any core that fails these tests is either discarded or sent for rework to correct any defects. This attention to detail ensures that the final product performs as expected in its application, be it in an electrical motor, transformer, or another electromagnetic device.

Pesquisar

Categorias

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leia mais

**EA FC 26 Coins Kaufen: Der Ultimative Leitfaden zum Schnellen und Sicherem Erwerb von FC26 Coins**

EA FC 26 Coins Kaufen: Der Ultimative Leitfaden zum Schnellen und Sicherem Erwerb von FC26 Coins...

「原神 チャージと課金:安全な課金サイトでリソースを増やす方法」

原神 チャージと課金:安全な課金サイトでリソースを増やす方法...

Unlocking Fun: How to Buy Golden Stickers and Send Stars in Monopoly GO

Unlocking Fun: How to Buy Golden Stickers and Send Stars in Monopoly GO

In the vibrant, bustling...

**EA FC 26 Coins Kaufen: Der Ultimative Leitfaden für FC26 Coins Kaufen und Strategien zum Coins Kaufen EA FC 26**

EA FC 26 Coins Kaufen: Der Ultimative Leitfaden für FC26 Coins Kaufen und Strategien zum...

Artificial Saliva Market, Excellent Growth Of Fintech Block Chain With Key Vendors by Fact MR

The global artificial saliva market is estimated at a value of US$ 1.28 billion in 2024....

© 2026 Scenario.press - libera espressione

Portuguese (Brazil)

Portuguese (Brazil)