Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

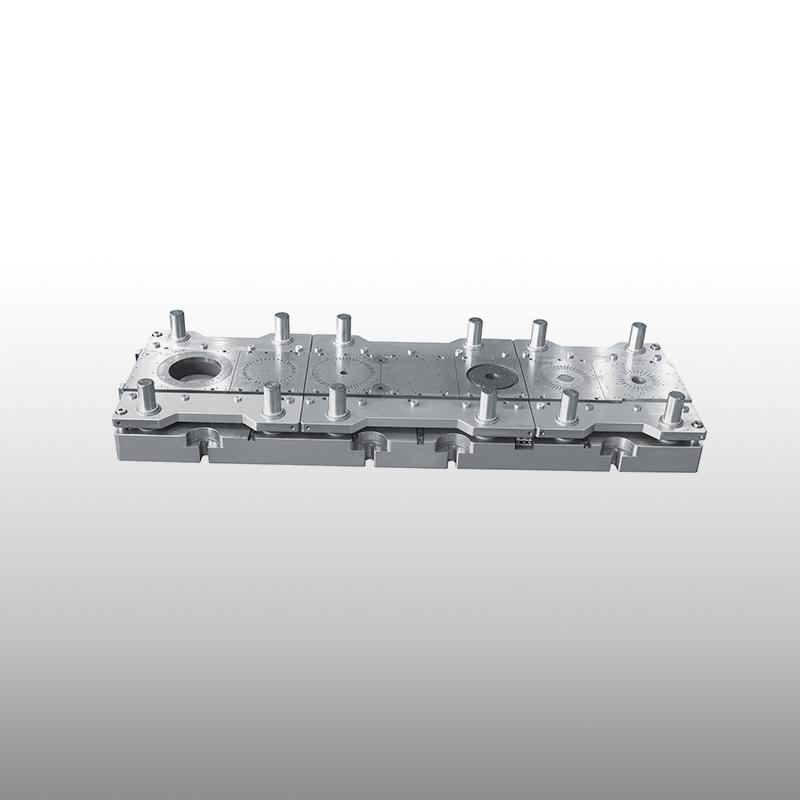

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Maximize Your Gameplay with FUT Coins FIFA and FC 26 Coins: A Comprehensive Guide to FC26 Coins for Ultimate Team Success

Maximize Your Gameplay with FUT Coins FIFA and FC 26 Coins

In the competitive world of football...

Cómo Vender Monedas FC26 y Maximizar Tus FIFA Coins: Guía Completa para Jugadores

Cómo Vender Monedas FC26 y Maximizar Tus FIFA Coins: Guía Completa para Jugadores...

Maximisez vos gains avec les FC 25 crédits pour un meilleur jeu dans FIFA

Maximisez vos gains avec les FC 25 crédits pour un meilleur jeu dans FIFA

Dans l'univers...

Guía Completa para Comprar Jugadores en FC 25: Precios y Estrategias Efectivas

Guía Completa para Comprar Jugadores en FC 25: Precios y Estrategias Efectivas

El...

Wan 2.6 and its Role in Modern Digital Awareness

Introduction

In the rapidly changing digital world, specific terms and keywords gain attention...

© 2026 Scenario.press - libera espressione

English

English