Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

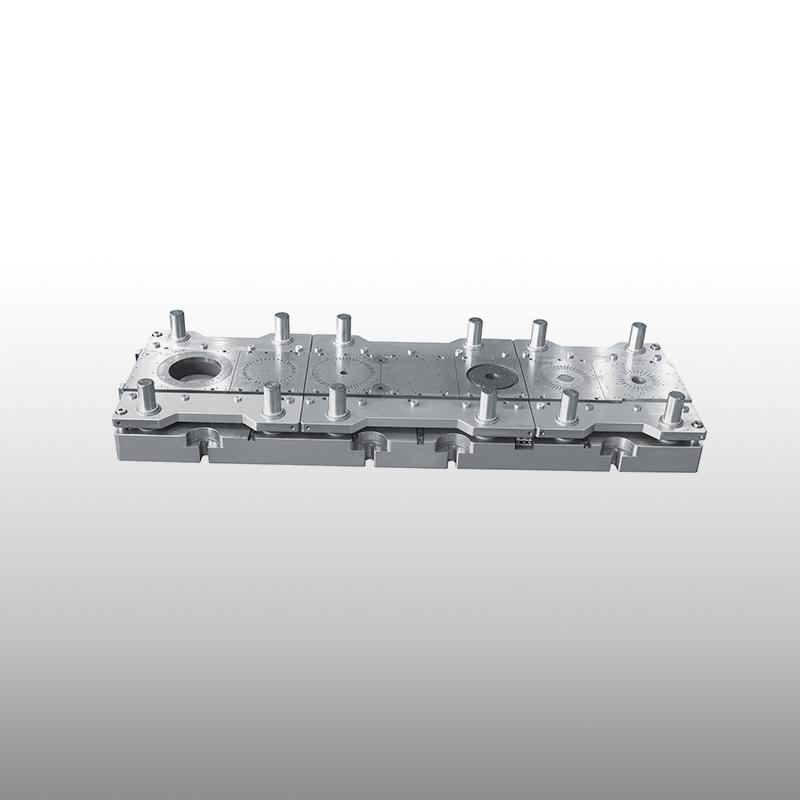

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

البحث

الأقسام

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

إقرأ المزيد

Título: "Cómo Vender y Comprar Monedas en EA FC 26: Guía Completa para Optimizar tus Transacciones

Cómo Vender y Comprar Monedas en EA FC 26: Guía Completa para Optimizar tus...

Escorts In Lahore

Lahore, the cultural and historical heart of Pakistan, pulsates with life and energy. From its...

Guía Completa para Vender Monedas EA FC 25 y Maximizar tus Ganancias en Monedas FIFA 25

Guía Completa para Vender Monedas EA FC 25 y Maximizar tus Ganancias en Monedas FIFA 25...

Todo Sobre los Precios de los Jugadores en FC 25: Guía Completa de Precios FC 25 Jugadores

Todo Sobre los Precios de los Jugadores en FC 25: Guía Completa de Precios FC 25 Jugadores...

How to Monetize Traffic: 10 Powerful Ways to Turn Visitors into Profit

1. Understanding the Basics of Traffic Monetization

Before you start monetizing, you need to...