Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

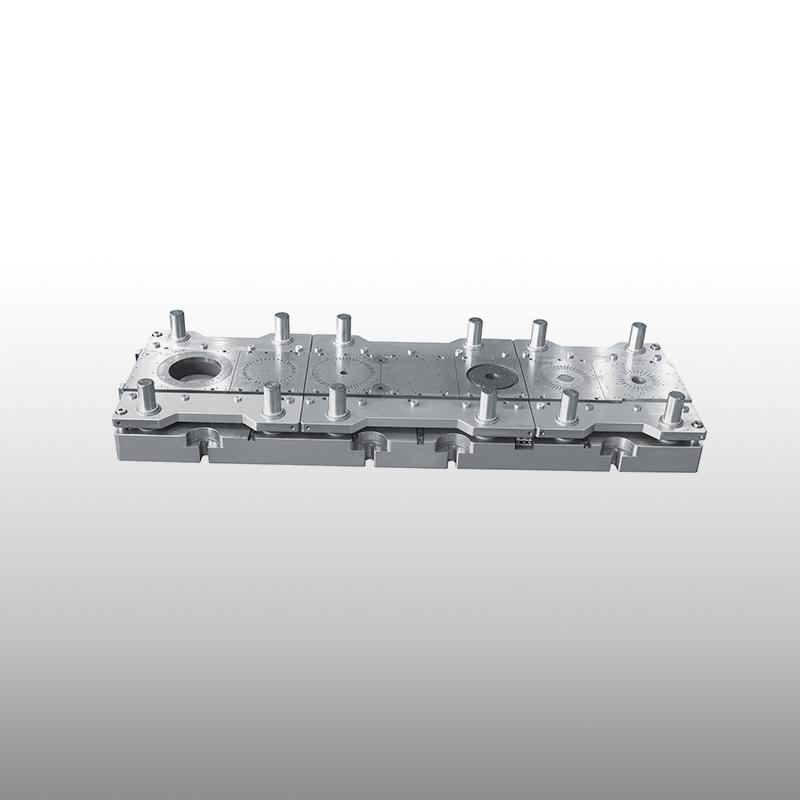

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Zoeken

Categorieën

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Titel: "Die besten Tipps zum FIFA Coins Verkaufen und FIFA 25 Münzen günstig kaufen: So sicher und schnell FC 25 Münzen kaufen!

Die besten Tipps zum FIFA Coins Verkaufen und FIFA 25 Münzen günstig kaufen: So sicher...

Die besten Tipps zum Poe2 Items kaufen: So sichern Sie sich wertvolle Poe2 Gold und Münzen!

Die besten Tipps zum Poe2 Items kaufen: So sichern Sie sich wertvolle Poe2 Gold und Münzen!...

Learning to Navigate Systems in Path of Exile 1 With Confidence

Path of Exile 1 does not hold the player’s hand. Its systems are layered, interconnected,...

Buy FIFA Coins for Sale: Unlock Ultimate Team Success with Affordable FC Coins Today!

Buy FIFA Coins for Sale: Unlock Ultimate Team Success with Affordable FC Coins Today!

In the...

Unlock the Game: Buy Cheapest FIFA 25 Coins and Level Up Your FC25 Experience Today!

Unlock the Game: Buy Cheapest FIFA 25 Coins and Level Up Your FC25 Experience Today!

In the...

© 2026 Scenario.press - libera espressione

Dutch

Dutch