From Design to Delivery: A Guide to Custom Metal Molds

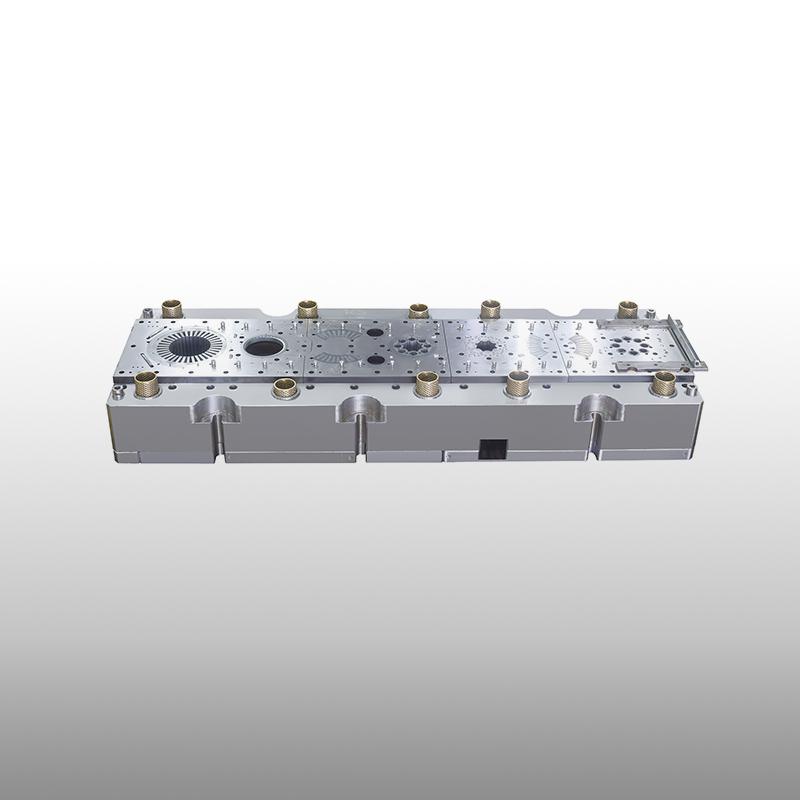

The initial step in the process of creating a custom metal mold is the design phase. This involves a detailed analysis of the part requirements, including dimensions, tolerances, material properties, and production volume. The design must take into account the manufacturing process that will be used, such as injection molding, die casting, or forging. It is crucial to work closely with engineers and designers to ensure that the mold design is feasible and can produce the desired results. Utilizing advanced CAD software can help in creating accurate 3D models of the mold, allowing for simulations and optimizations before the fabrication begins.

Pesquisar

Categorias

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leia mais

Which Market Trends Drive Canada Motorcycle Parts and Accessories Market?

Canada Motorcycle Parts and Accessories Market

The Canada Motorcycle Parts and Accessories...

Guida Completa ai Crediti FC 26 e FIFA 26: Come Ottenere FIFA Coins Rapidamente

Guida Completa ai Crediti FC 26 e FIFA 26: Come Ottenere FIFA Coins Rapidamente

Nel vasto...

Guía Completa de Precios FC 25 Jugadores: Descubre el Precio de Cada Jugador en FC 25

Guía Completa de Precios FC 25 Jugadores: Descubre el Precio de Cada Jugador en FC 25...

EA Sports FC 25: I giocatori con il più alto potenziale in Modalità Carriera

La Modalità Carriera di EA Sports FC 25 offre l'opportunità di sviluppare giovani...

Future-Proofing Your Digital Marketing Strategy in 2025

Introduction

Digital marketing is evolving faster than ever. In 2025, brands must navigate a...

© 2026 Scenario.press - libera espressione

Portuguese (Brazil)

Portuguese (Brazil)