From Design to Delivery: A Guide to Custom Metal Molds

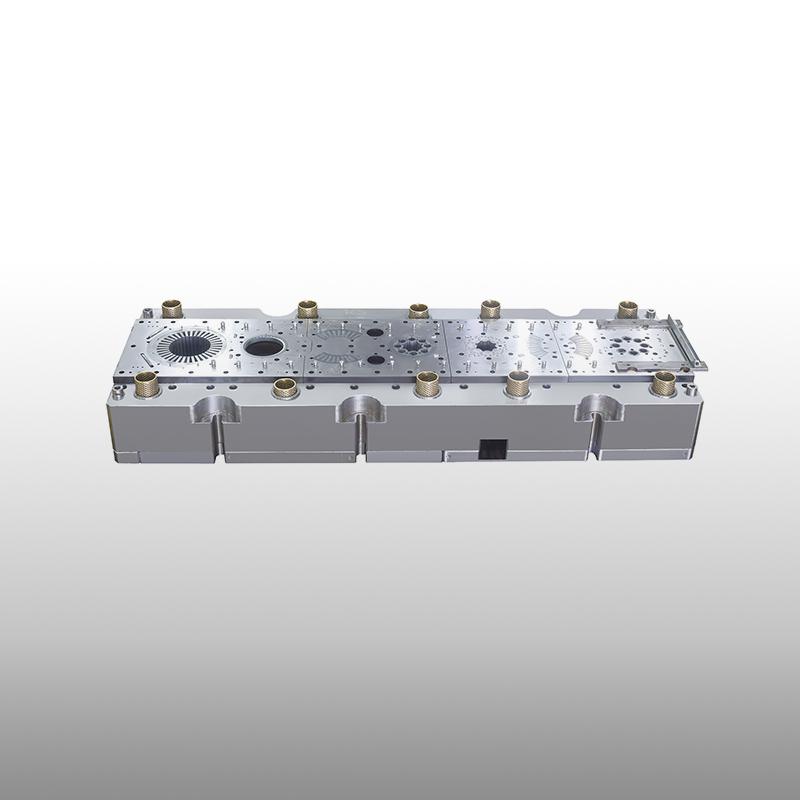

The initial step in the process of creating a custom metal mold is the design phase. This involves a detailed analysis of the part requirements, including dimensions, tolerances, material properties, and production volume. The design must take into account the manufacturing process that will be used, such as injection molding, die casting, or forging. It is crucial to work closely with engineers and designers to ensure that the mold design is feasible and can produce the desired results. Utilizing advanced CAD software can help in creating accurate 3D models of the mold, allowing for simulations and optimizations before the fabrication begins.

Zoeken

Categorieën

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Maximize Your Game: How to Earn and Trade FC25 Coins for FIFA Coins Effectively

Maximize Your Game: How to Earn and Trade FC25 Coins for FIFA Coins Effectively

Are you ready to...

Unlock the Best Deals on FIFA Coins Cheapest: Your Guide to EA Sports FC 26 Coins and FC 26 Coins

Unlock the Best Deals on FIFA Coins Cheapest: Your Guide to EA Sports FC 26 Coins and FC 26 Coins...

How Environmental Changes Impact the Durability of Invisible Door Locks

Influence of Environmental Factors on Invisible Door Locks

Invisible Door Locks are engineered...

Titre : "Acheter Crédit FC 25 : Maximisez Votre Expérience de Jeu avec FC 25 Credit

Acheter Crédit FC 25 : Maximisez Votre Expérience de Jeu avec FC 25 Credit

Dans...

Zwischen Erbe und Selbstbestimmung: Was wir von Klara-Magdalena Martinek über innere Klarheit lernen können

In einer Welt, die sich immer schneller dreht, suchen wir oft nach Ankern, die uns Halt geben und...

© 2026 Scenario.press - libera espressione

Dutch

Dutch