How Master Batches Improve Color Consistency and Product Performance?

Master batches are an integral part of modern plastic manufacturing, offering a convenient and efficient solution for incorporating various additives, colors, and properties into plastic products. These concentrated mixtures of pigments, fillers, and additives are used in the production of plastic items to enhance their appearance, improve their performance, and tailor them for specific applications. Although small in volume, master batches have a significant impact on the final product's quality and functionality.

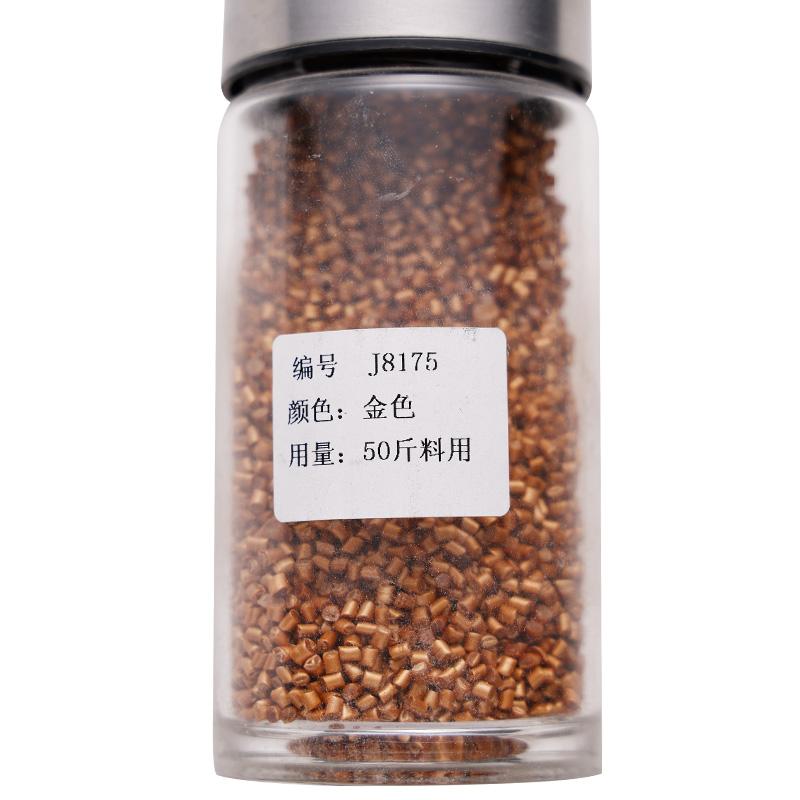

At its core, a master batch is a concentrated form of a substance that is mixed into the base plastic material during the production process. This mixture is typically in the form of a pellet or granule, making it easy to handle and incorporate into the plastic. For manufacturers, the use of master batches simplifies the process of colorant addition and functional enhancement. Instead of mixing raw powders or liquids directly with the plastic, which can be messy and inconsistent, the master batch provides a more controlled and precise method for achieving the desired results.

One of the primary uses of master batches is coloring plastic products. These batches contain pigments or dyes, allowing manufacturers to introduce a wide range of colors into plastic materials. The benefit of using master batches for color is that it ensures uniformity and consistency across large production runs. Without master batches, color variation can become a significant issue, especially in high-volume manufacturing. Master batches eliminate this concern, ensuring that the color remains consistent throughout the entire batch of plastic products.

Beyond just coloring, master batches are also used to modify the physical and chemical properties of plastics. They can contain various additives, such as UV stabilizers, antioxidants, flame retardants, and plasticizers. These additives improve the performance of plastic products by enhancing their resistance to environmental factors, increasing their durability, and making them suitable for specific uses. For example, plastics used in outdoor applications may require UV stabilizers to prevent degradation from sunlight exposure, while certain industrial applications may demand flame retardant properties for safety reasons.

Another advantage of master batches is their cost-effectiveness. Since master batches are concentrated, manufacturers only need to use a small amount to achieve the desired result, reducing material costs and minimizing waste. Additionally, the precision and consistency offered by master batches can lead to fewer defects and rework in the production process, further improving overall efficiency. For companies looking to optimize their manufacturing processes, the use of master batches can contribute to more streamlined operations and better resource management.

As industries increasingly focus on sustainability, master batches can also play a role in reducing the environmental impact of plastic production. Manufacturers are now able to produce master batches using recycled materials or biodegradable additives, offering a more eco-friendly option for producing plastic products. By incorporating sustainable practices into their manufacturing processes, companies can reduce their carbon footprint and contribute to a circular economy.

In summary, master batches are an essential component in the plastic manufacturing process. Their ability to simplify coloring, enhance performance, and improve cost efficiency makes them a valuable tool for manufacturers. As the demand for more specialized and sustainable plastic products continues to grow, master batches will likely remain an important part of the industry, offering solutions that meet both functional and environmental requirements.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness