Magnetic Powder Brakes: Enhancing Safety and Performance in High-Speed Applications

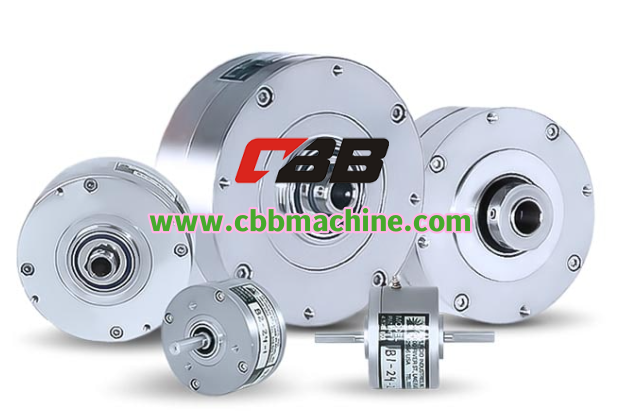

In the quest for flawless control over motion and tension, industries increasingly turn to advanced technologies that combine reliability with adaptability. Among these, the Magnetic Powder Brake has become indispensable, offering unparalleled precision in torque management. CBBMachine, a leader in industrial automation solutions, has elevated this technology to new heights, empowering sectors like printing, packaging, and robotics to achieve seamless operational harmony. By integrating cutting-edge engineering with user-centric design, CBBMachine’s innovations address the growing demand for efficiency in fast-paced production environments.

Precision Without Compromise

At the heart of the Magnetic Powder Brake lies a sophisticated mechanism that uses magnetic particles to regulate torque without physical contact. This unique design eliminates mechanical wear, ensuring consistent performance even under prolonged use. For industries such as wire winding or film processing, where even minor fluctuations can lead to costly defects, this technology guarantees uniform tension control. CBBMachine enhances this capability with customizable torque ranges and rapid response times, enabling businesses to fine-tune operations for maximum output and minimal waste.

Applications Spanning Modern Industry

The versatility of the Magnetic Powder Brake makes it a cornerstone of diverse workflows. In printing presses, it ensures precise web tension, preventing misalignment and reducing material waste. For automotive assembly lines, its ability to manage high-speed rotations improves safety during component fabrication. Even in renewable energy sectors, such as wind turbine manufacturing, the brake’s precision supports the production of durable, high-tolerance parts. CBBMachine’s solutions are engineered to integrate effortlessly with both traditional machinery and smart factory ecosystems, bridging the gap between legacy systems and Industry 4.0 innovations.

Durability in Challenging Conditions

Industrial environments often subject equipment to extreme conditions, from humidity to abrasive particulates. The Magnetic Powder Brake excels here, thanks to its sealed construction and heat-resistant materials. Unlike conventional brakes prone to overheating, CBBMachine’s design dissipates thermal energy efficiently, maintaining performance in continuous operation. This resilience is critical for industries like food packaging, where equipment must endure frequent sanitization, or metalworking, where dust and debris are unavoidable. Rigorous testing ensures each unit exceeds industry durability standards, delivering long-term value.

Sustainability Through Intelligent Design

As industries prioritize eco-conscious practices, the Magnetic Powder Brake supports sustainability goals. Its energy-efficient operation reduces power consumption, while the absence of mechanical wear minimizes replacement cycles and material waste. CBBMachine further amplifies this impact by using recyclable components and optimizing production processes to lower carbon emissions. By choosing this technology, businesses not only enhance productivity but also contribute to greener manufacturing practices.

A Partnership Built on Expertise

CBBMachine’s commitment extends beyond delivering superior hardware. The company offers end-to-end support, including installation guidance, operator training, and predictive maintenance programs. Their engineers collaborate with clients to develop tailored configurations, ensuring seamless integration into existing workflows. Real-time diagnostics and IoT-ready models provide actionable insights, enabling proactive adjustments to meet evolving demands. This collaborative approach transforms the Magnetic Powder Brake from a component into a strategic asset for growth.

Embracing Tomorrow’s Industrial Landscape

The future of manufacturing demands tools that blend precision with adaptability. CBBMachine’s Magnetic Powder Brake exemplifies this ethos, with innovations like AI-driven torque optimization and compatibility with autonomous systems. As industries evolve, this technology will remain pivotal in driving efficiency, safety, and sustainability across global supply chains.

Welcome to visit our website: https://www.cbbmachine.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness