How to Properly Extend the Service Life of Precision Peristaltic Pump Silicone Tubing:

How to Properly Extend the Service Life of Precision Peristaltic Pump Silicone Tubing:

Peristaltic pumps work by alternately squeezing and releasing tubing to pump fluids. Therefore, extending tubing life directly impacts the pump's operating time. However, the same tubing may break after two days of use in some cases, while lasting hundreds or even thousands of hours in others. This is closely related to daily usage habits. Here are some suggestions for improving the service life of peristaltic pump tubing:

Release Pressure When Not in Operation:

When the peristaltic pump is not in use, promptly release the pump's pressure block, allowing the tubing to remain in an uncompressed state, which significantly extends its service life.

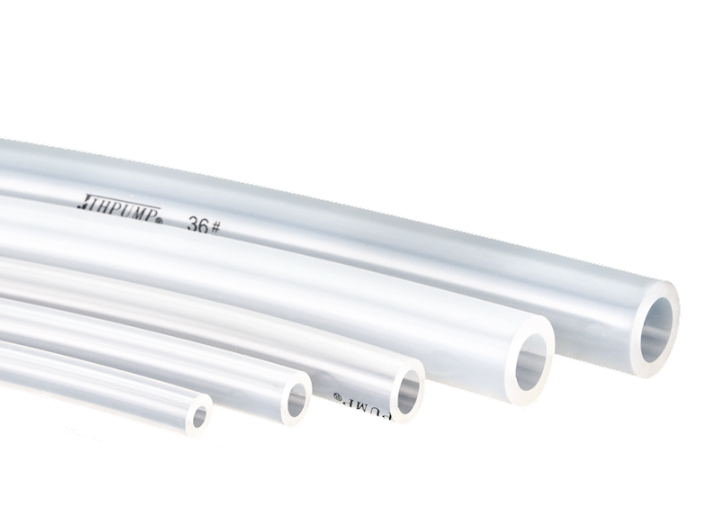

Use Dedicated Pump Tubing:

Ensure that the connection to the pump head uses dedicated peristaltic pump silicone tubing, which has stronger compression resilience and tear resistance, making it less prone to damage. Although relatively expensive, it is recommended for critical areas, while ordinary tubing can be used for other connections.

Choose Appropriate Pump Head and Speed:

Flow rate largely depends on the pump head's rotation speed. When meeting flow requirements, try to select a pump head with a larger flow rate to reduce operating speed and thus extend tubing life.

Confirm Fluid Compatibility:

Before selecting peristaltic silicone tubing, confirm the properties of the fluid being transported. If the liquid is corrosive, use a chemical compatibility chart or immersion test to select suitable tubing.

Maintain Cleanliness:

Keep the peristaltic pump's outer casing clean, especially by promptly removing residues on the tubing and where the tubing contacts the pressure block. Liquid adhering to the pump case's pressure rollers, pressure blocks, and tubing can alter the pump head's compression gap, leading to excessive tubing wear and, in severe cases, affecting the pump head.

Regular Inspection and Replacement:

This is particularly important. Always carefully inspect the tubing for wear before use and replace it promptly to avoid unnecessary trouble and losses due to leakage.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness