Measurement Tolerance Standards: Ensuring Precision in Modern Engineering

In the fast-advancing world of engineering, manufacturing, and automation, high accuracy is no longer a luxury—it is a necessity. Whether designing precision components for robotics, machining critical aerospace parts, or developing compact motion-control systems like harmonic drives and cycloidal gear motors, one principle binds all these processes together: Measurement Tolerance Standards.

For organizations and manufacturers striving for superior quality, consistency, and reliability, understanding and applying measurement tolerances is the foundation for error-free production. At Me Virtuoso, where innovation meets engineering excellence, integrating proper tolerance standards ensures that every product aligns with global benchmarks for precision.

What Are Measurement Tolerance Standards?

Measurement tolerance refers to the allowable deviation from a specified dimension. Since achieving perfect measurements is nearly impossible due to material properties, machining limitations, and environmental factors, tolerance sets the acceptable range of variation.

For example, if a shaft diameter is specified as 20 mm ± 0.01 mm, it means any diameter between 19.99 mm and 20.01 mm is considered acceptable.

These standards keep production both realistic and reliable by ensuring:

-

Proper fitting between components

-

Long-term durability

-

Reduced risk of system failure

-

Enhanced interchangeability

-

Consistency across manufacturing batches

Without measurement tolerance standards, even minor variations could result in catastrophic mechanical failures.

Why Tolerance Standards Matter in Modern Engineering

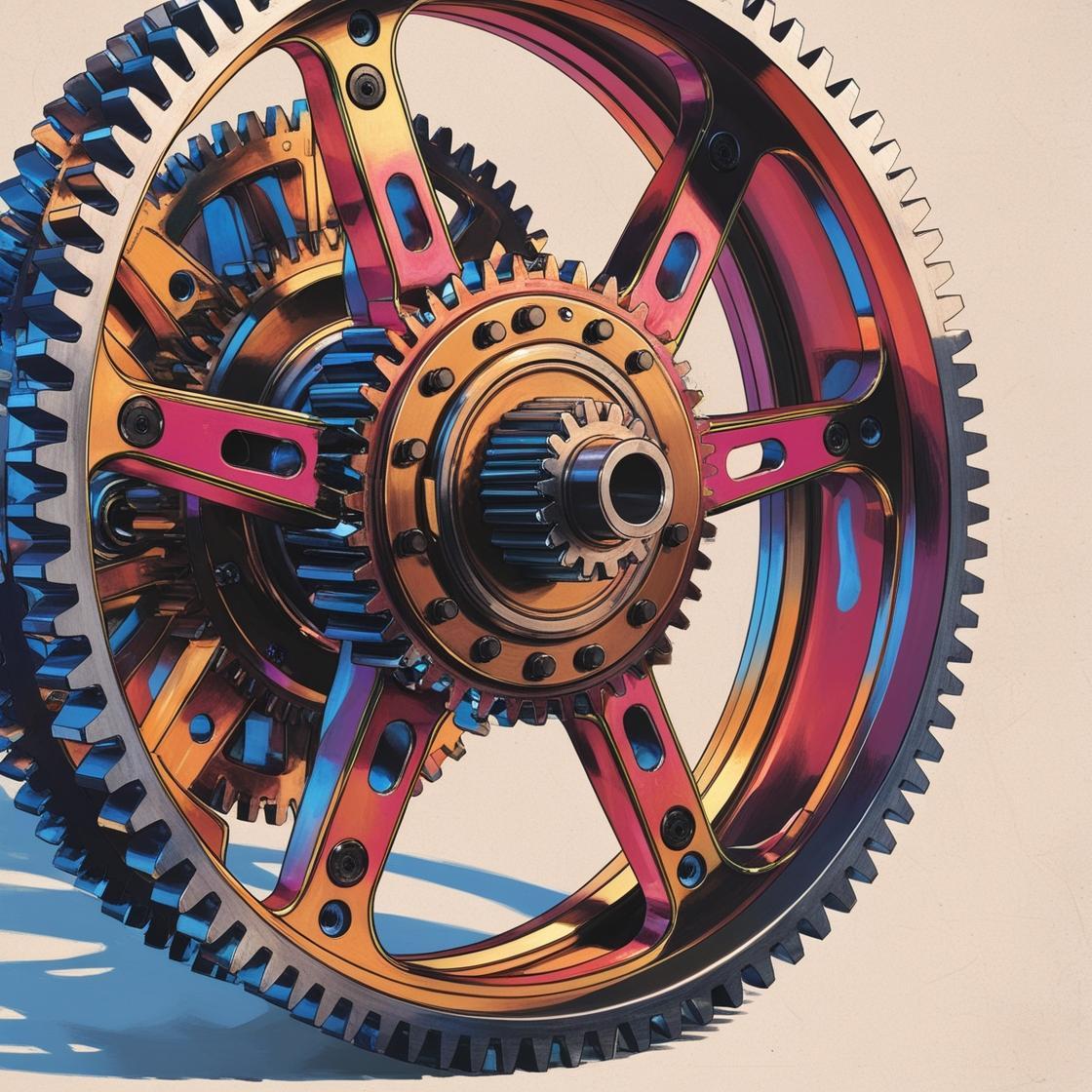

1. Precision in High-Performance Gear Systems

In advanced systems like harmonic drive actuators and cycloidal drive gearboxes, micro-level precision is essential. A slight deviation in gear teeth geometry or bearing placement can disrupt load capacity and torque transmission.

By adhering to strict tolerance standards, manufacturers ensure optimal efficiency and extended component lifespan.

2. Compatibility & Interchangeability

Production environments often involve multiple teams, machines, and suppliers. Tolerances guarantee compatibility between parts regardless of where or when they were produced.

This is especially vital in:

-

Automation systems

-

Aerospace components

-

Medical equipment

-

Robotics and industrial machinery

3. Enhanced Quality Control

Measurement tolerance standards provide a benchmark for inspection teams, allowing them to verify product quality quickly. This leads to:

-

Faster audits

-

Fewer product rejects

-

Better defect tracking

-

Higher customer satisfaction

4. Cost Optimization

Overly tight tolerances require expensive manufacturing processes, while excessively loose tolerances compromise quality. Balancing tolerances according to application ensures optimized cost without sacrificing performance.

Types of Measurement Tolerances

1. Linear Tolerance

Applied to lengths, widths, and heights. Example: ±0.05 mm.

2. Angular Tolerance

Used in components requiring precise angles, such as gear teeth.

3. Geometric Dimensioning & Tolerancing (GD&T)

Defines the allowable variation in form, orientation, and position. Examples include:

-

Flatness

-

Cylindricity

-

Concentricity

-

True position

GD&T is key in sophisticated gear systems used by Me Virtuoso’s engineering clients.

4. Surface Finish Tolerances

Critical in applications involving friction, wear resistance, and lubrication.

Global Measurement Tolerance Standards

Several international standards regulate tolerance definitions and applications:

-

ISO 2768 – General tolerances

-

ISO 286 – Fits and tolerances

-

ASME Y14.5 – GD&T standards

-

DIN standards – Widely used in European manufacturing

Adhering to these ensures global compatibility, making Me Virtuoso’s engineering solutions internationally competitive.

How Tolerance Standards Improve Mechatronics & Motion Control Systems

1. Efficient Power Transmission

High-precision tolerance in gears, bearings, and shafts ensures smooth power flow, especially in:

-

Cycloidal drive gearboxes

-

Harmonic drive actuators

-

Servo motors

2. Reduced Vibrations and Noise

Precision minimizes backlash and eccentricity, leading to quieter, more stable systems.

3. Higher Load Capacity

Tolerances ensure that load-bearing surfaces are aligned correctly, reducing stress concentration.

4. Superior System Reliability

Components manufactured with tight tolerance standards exhibit significantly longer service life and reduced downtime.

Challenges in Maintaining Tolerances

While essential, precision manufacturing comes with challenges:

-

Advanced machinery and tooling required

-

Skilled professionals needed

-

Increased cost for ultra-tight tolerances

-

Need for regular calibration of equipment

However, the benefits far outweigh the limitations for applications where reliability and efficiency are mission-critical.

The Future of Measurement Tolerance Standards

As automation and Industry 4.0 continue to evolve, tolerance standards will become even more refined. AI-driven inspection, digital twins, and automated metrology systems are poised to revolutionize accuracy and repeatability.

Me Virtuoso is committed to adapting to these advancements, offering high-performance motion-control solutions built on uncompromising precision.

Frequently Asked Questions (FAQ)

1. Why are measurement tolerance standards necessary?

They ensure parts fit correctly, function reliably, and maintain product quality across production batches.

2. What happens if tolerances are too tight?

Manufacturing costs rise significantly due to stricter machining requirements and higher inspection needs.

3. Which industries rely heavily on tolerance standards?

Aerospace, robotics, automotive, medical equipment, electronics, and high-precision gearbox manufacturing.

4. What is the difference between tolerance and GD&T?

Tolerance defines allowable dimensional variation, while GD&T defines variation in geometry, orientation, and position.

5. How does Me Virtuoso benefit from applying tolerance standards?

It ensures superior-quality components, higher performance in gear systems, and improved customer satisfaction.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness