What Features Should a Quality Digital Pressure Gauge Include for Reliability?

A Digital Pressure Gauge plays an essential role in many modern industrial systems. It measures pressure with precision, displays readings clearly, and supports operators who require dependable information in real time. A high quality design enhances safety and ensures consistent operation in demanding environments. A reliable instrument must combine strong engineering, stable electronics, and thoughtful usability features. In this article, we explore the characteristics that define a dependable Digital Pressure Gauge and explain why each feature matters. The discussion uses simple clauses and includes both main and subheadings to maintain clarity.

Core Requirements for a Reliable Digital Pressure Gauge

Accuracy as the Foundation of Reliability

Accuracy forms the foundation of reliability. A reliable Digital Pressure Gauge must deliver readings that reflect true system conditions. Accurate measurement supports safe operation. It protects equipment from damage. It also allows operators to make informed decisions. Accuracy depends on sensor quality and calibration stability. A high quality sensor responds consistently to pressure changes. Stable internal electronics protect the reading from noise or drift. A dependable gauge holds accuracy over long periods. It does not require constant recalibration. This stability builds trust. It allows the gauge to become a central tool in a process.

Resolution and Measurement Range

Resolution helps the operator see fine changes in pressure. A reliable Digital Pressure Gauge presents small increments clearly. Clear resolution supports early detection of unusual behavior. It helps identify trends and predict issues. The measurement range also matters. A quality gauge covers the full pressure span required in the application. It does not saturate under high pressure. It does not lose sensitivity at low pressure. A balanced range and resolution design ensures consistent performance. It ensures that the gauge remains useful in complex and dynamic systems.

Physical Durability and Environmental Protection

Strong and Robust Construction

A reliable Digital Pressure Gauge must handle physical stress. Its housing must resist impact. Its internal components must withstand vibration. Many industrial settings expose instruments to harsh conditions. A strong body prevents cracks, deformation, or loose components. A stable mounting system ensures that the gauge maintains alignment. A durable instrument reduces downtime. It also protects measurement accuracy. A high quality gauge uses metals or engineered plastics that resist fatigue. Construction quality influences long term reliability more than many users realize.

Protection Against Dust, Moisture, and Corrosion

Environmental protection supports stable operation in difficult conditions. Moisture can damage electronics. Dust can cause interference. Chemicals can corrode surfaces. A reliable Digital Pressure Gauge is sealed against these threats. An appropriate protection rating confirms that the gauge can operate outdoors or in wash down conditions. Sealing prevents moisture from entering the device. A corrosion resistant surface protects exposed parts. Strong environmental protection ensures stable performance. It also extends the service life of the gauge. This makes the instrument more economical over time.

Display and Interface Considerations

Clear and Readable Display

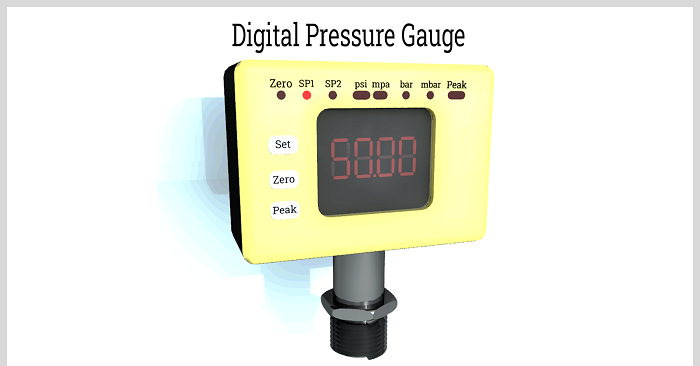

A clear display helps the operator read values easily. A reliable Digital Pressure Gauge uses a bright screen. It uses large numbers. It avoids clutter. Clear visibility improves safety. It reduces confusion. A high contrast display helps in bright conditions. A backlit display helps in dim conditions. The display must maintain readability across temperatures. It must not fade or distort. A good interface represents readings in a simple and direct manner. The clarity of the display directly affects the usefulness of the gauge.

Intuitive Controls and Simple Functions

An intuitive interface supports efficient operation. A reliable Digital Pressure Gauge uses simple buttons. It offers clear menus. It allows quick access to essential functions. Operators should not struggle to configure the device. A simple interface reduces training time. It reduces mistakes. Features like zeroing, units switching, or peak hold should be easy to access. Each function must behave consistently. A quality design eliminates confusion. It ensures that the gauge becomes a helpful tool rather than a complicated obstacle.

Sensor Technology and Electronic Stability

Stable and High Quality Sensors

Sensor design influences every aspect of reliability. A Digital Pressure Gauge uses sensors such as piezoresistive, capacitive, or strain gauge elements. A stable sensor responds accurately to pressure changes. It must resist drift. It must recover quickly after overload. A high quality sensor also resists temperature changes. It maintains linearity. It reduces error. Sensor quality determines the long term value of the instrument. The more stable the sensor, the more dependable the gauge becomes.

Noise Reduction and Signal Processing

Electronic stability protects the reading from interference. A reliable Digital Pressure Gauge uses clean signal processing. It filters noise. It stabilizes the display. It prevents jumps or fluctuations. Proper shielding protects the electronics from electromagnetic interference. Stable processing ensures the displayed reading matches the actual pressure. Good electronics also improve battery life and reduce errors. A high quality gauge uses components that hold stability for years. This stability supports consistent measurement even under changing conditions.

Power Systems and Long Term Reliability

Efficient Power Use and Battery Life

A reliable Digital Pressure Gauge uses power efficiently. It does not drain batteries quickly. It may use sleep modes. It may reduce display brightness automatically. Long battery life supports reliable operation in remote locations. It reduces maintenance. It prevents unexpected shutdowns. A quality gauge also provides clear battery indicators. It warns the operator before the power becomes low. This transparency protects operations from interruption.

Power Stability and Backup Features

Power stability protects measurement consistency. A reliable Digital Pressure Gauge does not reset unexpectedly. It must maintain memory settings during power loss. Backup systems ensure that the gauge continues to function in demanding applications. Power stability prevents errors and protects data. Many process environments require uninterrupted monitoring. Stable power design makes the gauge more dependable in these situations.

Advanced Functions for Improved Reliability

Data Logging and Trend Monitoring

Data logging helps track system changes over time. A quality Digital Pressure Gauge records readings at intervals. This information supports troubleshooting. It helps identify failures before they occur. Trend monitoring offers insight into pressure cycles. It reveals patterns. It supports predictive maintenance. These functions make the gauge more than a measuring tool. They make it a process insight device. Reliability improves when data supports informed decisions.

Communication and Connectivity

Modern systems require connectivity. A reliable Digital Pressure Gauge may include communication options. It may interface with control systems. It may send alerts. Communication improves efficiency. It ensures that pressure data enters the larger process network. Connectivity supports automation. It supports monitoring from a distance. This integration increases the overall reliability of the system. It ensures that the gauge plays an active role in process control.

Conclusion

A Digital Pressure Gauge becomes reliable when it combines accuracy, durability, clarity, sensor stability, and intelligent features. Every part of the design supports dependable performance. A strong body resists damage. A clear display supports reading. Advanced electronics protect accuracy. Power stability and data functions enhance long term value. By understanding these features, users can choose gauges that perform consistently in demanding environments. A reliable Digital Pressure Gauge supports safety, efficiency, and confidence in every application.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness