How Does Pressure Drop Occur in an Orifice Plate Flow Meter System?

In industrial flow measurement, understanding the relationship between pressure and flow is crucial. One of the most common instruments used for this purpose is the Orifice Plate Flow Meter. It is a simple and reliable device, known for its accuracy and durability. However, a key phenomenon associated with its operation is pressure drop. This pressure loss is a natural consequence of how the meter functions. To understand it fully, one must explore the principles of fluid dynamics, the structure of the orifice plate, and the way energy transforms as fluid flows through it.

Understanding the Basic Principle of the Orifice Plate Flow Meter

The Role of Flow Restriction

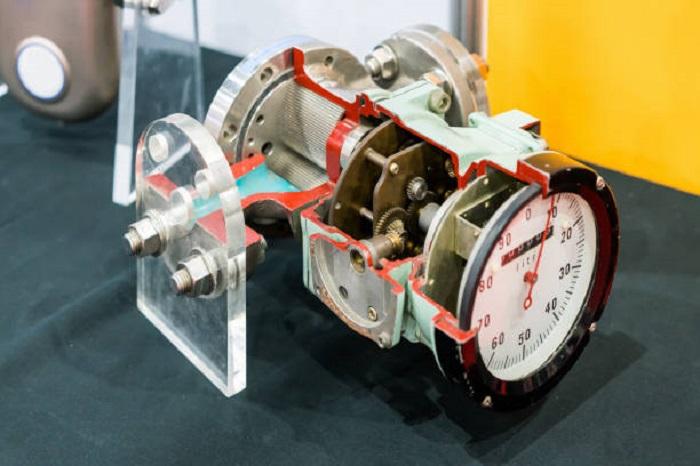

An Orifice Plate Flow Meter works on a simple mechanical principle. It introduces a restriction in the flow path by placing a thin metal plate with a small hole — the orifice — inside the pipeline. As the fluid passes through the narrow opening, its velocity increases and the pressure decreases. This change in velocity and pressure allows the measurement of flow rate through differential pressure.

The principle behind this system is Bernoulli’s equation, which states that an increase in velocity results in a decrease in pressure, assuming constant energy. The pressure difference between the upstream and downstream sides of the orifice plate is directly related to the flow rate.

The Function of Differential Pressure

The meter includes pressure taps located before and after the orifice plate. These taps measure the high pressure on the upstream side and the low pressure on the downstream side. The difference in pressure is used to calculate the flow rate. However, part of this pressure drop is not recovered after the flow returns to normal. This irreversible pressure loss is known as permanent pressure drop, and it represents energy dissipated as heat and turbulence.

The Nature of Pressure Drop in an Orifice Plate Flow Meter

Temporary and Permanent Pressure Changes

When fluid approaches the orifice, the cross-sectional area decreases, and velocity increases sharply. The pressure immediately drops as energy converts from pressure energy to kinetic energy. Just downstream of the orifice, the fluid passes through a point called the vena contracta, where the flow area is smallest and the velocity is highest.

After the vena contracta, the flow expands again, and some pressure recovery occurs. However, the total pressure never returns to its original value. The difference between the initial upstream pressure and the recovered downstream pressure represents the permanent pressure drop. This loss occurs due to friction, turbulence, and energy dissipation.

How Turbulence Affects Pressure Loss

Turbulence is one of the main causes of energy loss in an Orifice Plate Flow Meter. As fluid jets through the orifice, it mixes with slower-moving fluid behind the plate. This mixing produces eddies and vortices that dissipate energy. Since the fluid flow is rarely perfectly laminar, part of the pressure energy converts into heat. This process is irreversible, and the system must compensate for this energy loss through additional pumping power.

Factors Influencing Pressure Drop in Orifice Plate Flow Meters

Orifice Diameter and Beta Ratio

The size of the orifice opening has a major impact on pressure drop. Engineers describe this relationship using the beta ratio, which is the ratio of the orifice diameter to the pipe diameter. A smaller beta ratio means a smaller opening, which increases velocity and pressure drop. Conversely, a larger beta ratio reduces restriction but also lowers measurement sensitivity.

Finding the right balance is important. Too much restriction can lead to excessive energy loss, while too little restriction can make the meter less accurate.

Flow Velocity and Fluid Density

The speed of the fluid also affects pressure loss. As velocity increases, kinetic energy increases, and pressure drops more sharply. Dense fluids such as water or oil experience greater pressure loss than lighter gases because their inertia is higher. This relationship explains why orifice plates are carefully selected based on the specific process fluid and flow conditions.

Plate Design and Edge Sharpness

The shape and sharpness of the orifice edge are also significant. A sharp-edged orifice provides a clean break in the flow, resulting in predictable pressure characteristics. Over time, erosion or corrosion can dull the edge, changing the flow pattern and increasing turbulence. This can cause higher pressure loss and reduced measurement accuracy. Regular inspection and maintenance help maintain consistent performance.

Energy Transformation and Pressure Loss

Conversion of Pressure Energy to Kinetic Energy

When fluid passes through an Orifice Plate Flow Meter, part of its pressure energy converts into kinetic energy. The total energy remains constant, but its distribution changes. The high velocity through the orifice represents an increase in kinetic energy, while the drop in static pressure represents a loss in potential energy.

After passing the orifice, the velocity decreases again, and some pressure recovers. However, because of turbulence and viscous friction, not all the lost pressure is regained. The energy dissipated as turbulence and heat represents the permanent pressure drop.

Viscous and Frictional Losses

Friction between the fluid and the pipe walls contributes to pressure loss. Even in smooth pipes, viscosity causes resistance to flow. In the region near the orifice plate, these losses become more pronounced. The sudden contraction and expansion of flow increase frictional effects, leading to a larger permanent pressure loss than in straight pipe sections.

Practical Impact of Pressure Drop on System Performance

Increased Pumping Requirements

One direct effect of pressure drop is the need for additional pumping power. When an Orifice Plate Flow Meter is installed in a system, it introduces a permanent resistance to flow. The pump must work harder to maintain the same flow rate, consuming more energy. Although each individual loss may seem small, in large systems or networks, the cumulative energy demand can be significant.

This is why engineers often consider the trade-off between measurement accuracy and energy efficiency. Selecting the right orifice size helps minimize unnecessary pressure losses while still providing reliable data.

System Efficiency and Energy Costs

Pressure loss translates directly into higher operational costs. Over time, the additional energy required to overcome flow restriction adds to utility expenses. In industries such as oil and gas or water treatment, where fluids are moved continuously, this cost can be substantial.

To manage this, many facilities use computational models to predict pressure losses before installing flow meters. These models consider factors such as flow rate, fluid type, and pipe diameter. Accurate prediction ensures that the system operates efficiently without compromising measurement quality.

Design Considerations for Minimizing Pressure Drop

Optimal Beta Ratio Selection

Choosing the right beta ratio is essential for balancing accuracy and efficiency. A beta ratio between 0.4 and 0.75 is common in most Orifice Plate Flow Meter applications. This range provides a measurable differential pressure while keeping permanent pressure loss at manageable levels.

If the orifice is too small, the differential pressure may be easy to measure, but the system will lose too much energy. On the other hand, if the orifice is too large, the pressure differential will be too small for accurate measurement.

Streamlined Flow Conditioning

Proper flow conditioning upstream of the orifice plate can help reduce turbulence and improve pressure recovery. Straight pipe runs or flow straighteners ensure that the fluid enters the orifice uniformly. A uniform velocity profile reduces energy loss and enhances accuracy.

Engineers often recommend at least ten pipe diameters of straight length before the orifice plate. This practice allows the flow to stabilize and minimizes unnecessary turbulence that can amplify pressure drop.

Maintenance and Calibration

Over time, debris buildup or plate damage can alter the flow characteristics. Regular cleaning and calibration keep the pressure loss within the expected range. A damaged plate can cause unpredictable turbulence, which increases energy loss and measurement error. Routine maintenance preserves both efficiency and reliability.

Real-World Applications and Considerations

Industrial Use of Orifice Plate Flow Meters

Orifice Plate Flow Meters are widely used in industries such as chemical processing, oil refining, and power generation. Their simple design, low cost, and durability make them ideal for long-term use. In many cases, engineers accept a moderate pressure drop as a trade-off for reliable measurement and proven technology.

However, in systems where energy conservation is a priority, engineers may use advanced flow meters such as venturi or ultrasonic types. These alternatives offer lower pressure loss but come with higher purchase and maintenance costs.

Balancing Accuracy and Efficiency

Ultimately, the pressure drop in an Orifice Plate Flow Meter is both a limitation and a design feature. The differential pressure created by the restriction is necessary for measuring flow accurately. Without this drop, there would be no measurable signal. The challenge lies in optimizing design to achieve accurate readings while minimizing energy loss.

Conclusion

Pressure drop in an Orifice Plate Flow Meter is a fundamental result of its working principle. As fluid accelerates through the orifice, pressure decreases due to energy conversion and frictional effects. While part of this pressure is recovered, a permanent loss remains, representing energy dissipated as turbulence and heat.

Understanding this behavior helps engineers design efficient systems. By selecting the correct orifice size, maintaining sharp edges, and ensuring proper flow conditioning, they can reduce unnecessary losses. Although pressure drop cannot be eliminated, it can be managed effectively.

In industrial applications, this balance between precision and efficiency defines the value of the Orifice Plate Flow Meter. Its simplicity, reliability, and proven performance continue to make it a cornerstone of flow measurement, even in systems where pressure loss must be carefully controlled.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness