Evaluating the Benefits of Hot Runner Systems in Modern Plastic Pallet Molding

Introduction to Hot Runner Systems

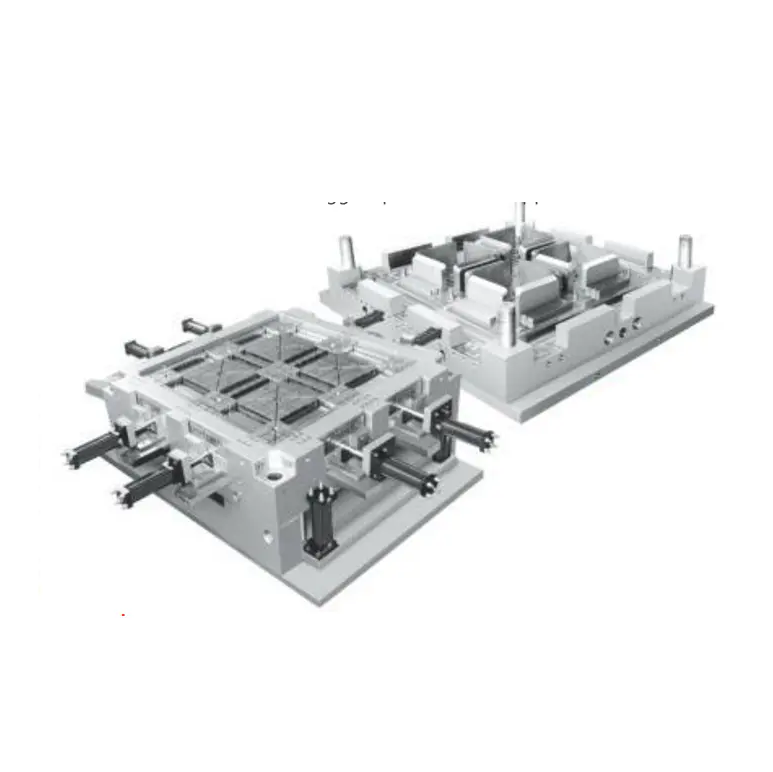

In modern injection molding, the efficiency of a Plastic Pallet Mold is heavily influenced by its material flow system. Traditional cold runner molds require the plastic to flow through channels that solidify along with the part, resulting in material waste and longer cycle times. Hot runner systems, by contrast, maintain the plastic in a molten state until it enters the mold cavity, reducing cooling delays and eliminating the need to trim runners after ejection. Integrating a hot runner can therefore have a significant impact on productivity, cost savings, and product consistency in pallet manufacturing.

Reducing Cycle Time with Continuous Flow

One of the primary advantages of a hot runner system is the reduction of overall cycle time. In conventional molds, the cold runners must solidify before the mold can open, which prolongs each production cycle. With a hot runner, the plastic remains at an optimal temperature within the channels, allowing immediate cavity filling without waiting for the runner to cool. This continuous flow not only accelerates the molding process but also enables faster repetition of cycles, which is particularly beneficial when producing large quantities of plastic pallets.

Material Savings and Waste Reduction

Another key benefit of using a hot runner in a Plastic Pallet Mold is material conservation. Cold runner molds generate excess plastic that solidifies in the channels, which often requires regrinding or disposal. Hot runner systems minimize or eliminate this waste, as only the part itself is injected into the mold cavity. This reduction in scrap lowers raw material costs and enhances environmental sustainability by reducing plastic waste. Additionally, the consistent temperature control in the hot runner prevents premature cooling or flow inconsistencies that could affect the final quality of the pallet.

Improved Part Quality and Surface Finish

Hot runner systems also contribute to better product quality. Maintaining the plastic at a uniform temperature ensures consistent flow into all areas of the mold cavity, reducing common defects such as sink marks, voids, or weld lines. The result is a more uniform density and smoother surface finish, which is especially important for pallets that require precise dimensions and high structural integrity. Furthermore, the absence of solidified runners prevents uneven stresses that could otherwise lead to warpage or distortion during ejection.

Design Considerations and Maintenance

While hot runner systems offer clear benefits, proper design and maintenance are essential. The system must be tailored to the size and complexity of the pallet mold, including considerations for nozzle placement, temperature zones, and thermal insulation. Periodic inspection and cleaning are necessary to prevent clogging or degradation of the heaters, ensuring consistent performance over time. Investment in a high-quality hot runner system pays off in terms of both production efficiency and long-term reliability.

Hot Runners as a Productivity Solution

Equipping a Plastic Pallet Mold with a hot runner system can significantly enhance injection molding efficiency. By reducing cycle time, minimizing material waste, and improving part quality, hot runners offer both economic and operational advantages. While initial investment and maintenance are required, the long-term gains in production speed, material savings, and product consistency make hot runner systems a valuable solution for high-volume pallet manufacturing.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness