The Role of Aluminum Coil Series in Automotive Manufacturing

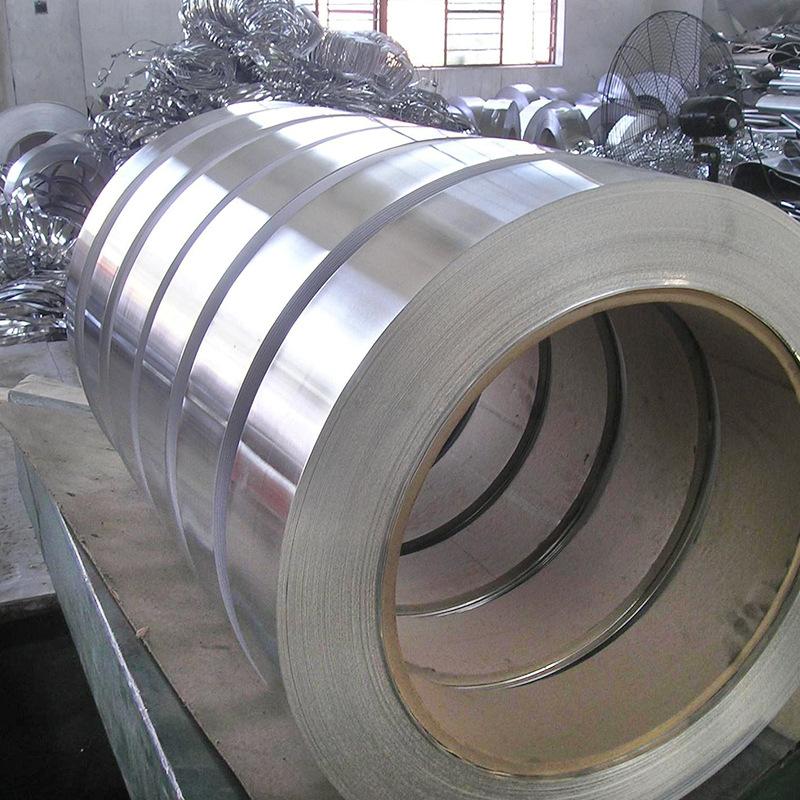

The automotive industry is in the midst of a profound transformation, driven by the dual mandates of electrification and sustainability. At the heart of this revolution is a material that has become a strategic asset: aluminum. Its high strength-to-weight ratio is the key to "lightweighting"—reducing vehicle mass to improve fuel efficiency and electric vehicle (EV) range. However, a car is a complex machine with parts that serve vastly different functions. This is where the different series of aluminum coil step into the spotlight, each playing a specialized role in building the modern, high-performance vehicle.

Lightweighting: The Ultimate Goal

Every kilogram of weight reduced in a vehicle translates directly to improved efficiency. For internal combustion engine (ICE) vehicles, this means better fuel economy and lower emissions. For EVs, it is even more critical; less weight means a smaller, lighter battery pack can achieve the same driving range, resulting in significant cost savings and resource conservation. Aluminum coil, formed into body panels, structural components, and closure parts, is the primary tool engineers use to achieve these weight reductions without compromising safety or performance.

A Tour of the Car: Matching the Alloy to the Application

1. Body Panels and Closure Parts: The 6xxx Series Dominance

Why it's used: The outer "skin" of the car—doors, hoods, trunk lids, and fenders—requires a fine balance. It needs to be formable enough to be stamped into complex, aesthetically pleasing shapes, strong enough to provide dent resistance, and must accept a high-quality paint finish.

The Alloy Fit: The 6xxx series (e.g., 6016, 6022) is the undisputed champion here. These heat-treatable alloys (containing Magnesium and Silicon) are supplied in a formable state (T4 temper) for stamping. After the forming process, they pass through the paint shop's curing oven, which acts as an artificial aging process, boosting the panel's strength and dent resistance to its final state (T6 temper). This "bake-hardening" characteristic is a perfect synergy with automotive manufacturing.

2. Structural Components and Crash Management: The Strength of 7xxx

Why it's used: For parts that manage crash energy and form the vehicle's safety cage—such as bumper beams, crash boxes, and A-pillars—exceptional strength is non-negotiable.

The Alloy Fit: The 7xxx series alloys, primarily with Zinc as the main alloying element, offer the highest strength of all aluminum alloys, rivaling some steels. While traditionally harder to form, advancements in manufacturing have made them viable for these critical, life-saving components. Their use allows for thinner, lighter sections that can absorb immense energy during a collision.

3. Heat Exchangers and Cooling Systems: The 3xxx Series Workhorse

Why it's used: Radiators, charge air coolers, and evaporators need excellent thermal conductivity, corrosion resistance, and the ability to be easily brazed—a process where components are joined using a filler metal.

The Alloy Fit: The 3xxx series (Manganese-alloyed) is the standard. It is inherently corrosion-resistant, formable, and its brazing characteristics are well-understood and reliable. It is the unsung hero that keeps engines and battery packs operating at optimal temperatures.

4. Interior Trim and Battery Enclosures: A Mix of 5xxx and 6xxx

Why it's used: Interior components require good formability and a class-A surface finish. For EVs, the battery enclosure is a critical component that must be strong, protective, and lightweight.

The Alloy Fit: 5xxx series (Magnesium-alloyed) alloys are often used for interior trim due to their excellent formability. For battery enclosures, both 5xxx and 6xxx series are employed. The 5xxx offers great formability and strength without heat treatment, while 6xxx can be used for extruded side members that provide structural integrity to the pack.

The Future is Multi-Material and Multi-Series

No single aluminum series can build a car. The modern vehicle is a sophisticated multi-material assembly, and aluminum's role within it is equally nuanced. Engineers are becoming material chefs, carefully selecting a 7xxx series for the bumper, a 6xxx for the roof, and a 3xxx for the radiator to create the perfect recipe of safety, efficiency, and performance. As the push for sustainability intensifies, this precise application of specific aluminum coil series will remain a cornerstone of automotive innovation, helping to drive us into a cleaner, more efficient future.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness