Epoxy Resins Market Outlook 2035 | Innovations in Sustainable Composites and Expanding Industrial Applications to Drive Steady Growth

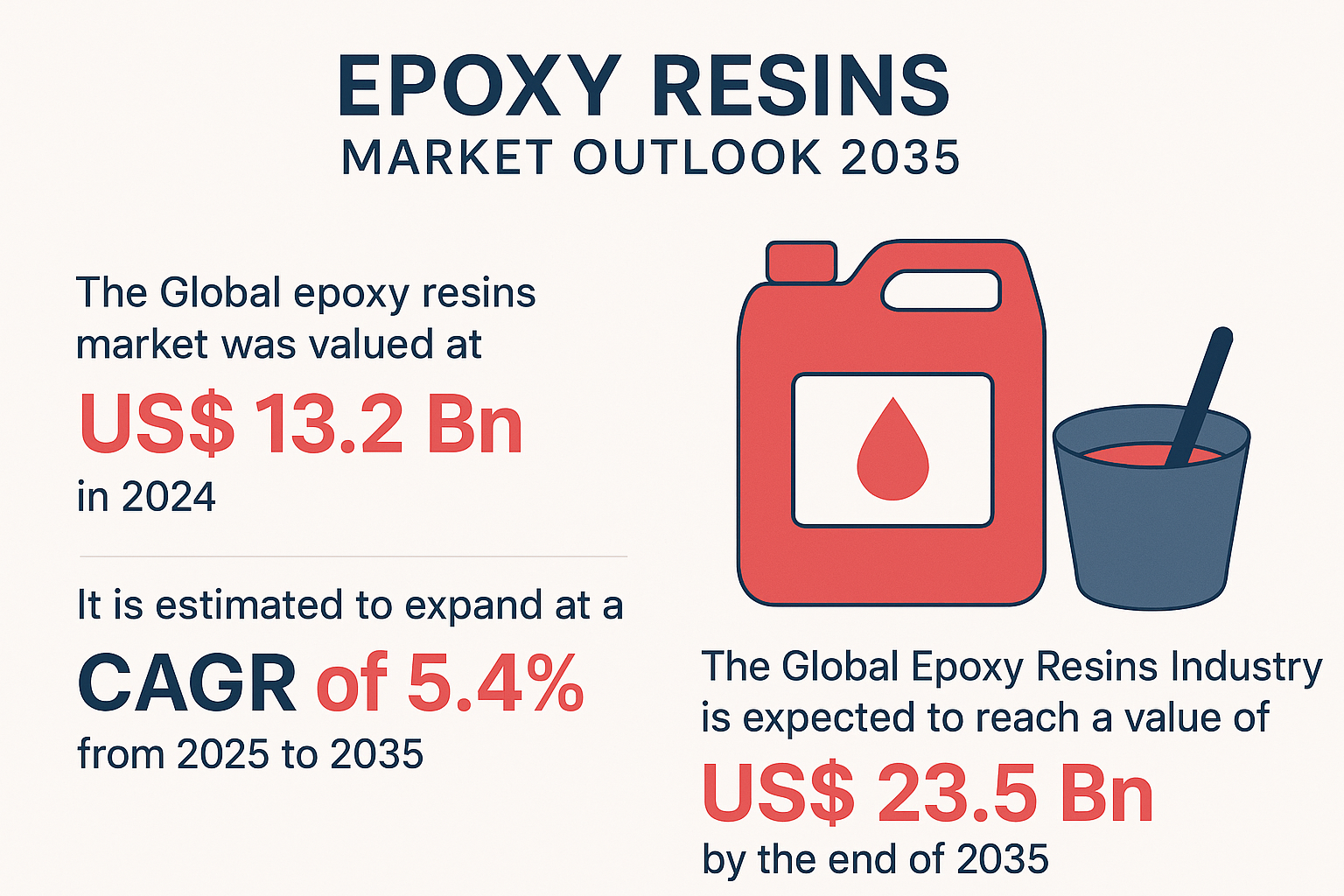

The global epoxy resins market is poised for consistent expansion over the next decade, driven by increasing demand from construction, automotive, aerospace, and electronics sectors. Valued at US$ 13.2 billion in 2024, the market is projected to grow at a CAGR of 5.4% from 2025 to 2035, ultimately reaching US$ 23.5 billion by 2035. The shift toward lightweight, high-performance, and eco-friendly materials is reshaping industry dynamics, with manufacturers investing heavily in sustainable innovations such as bio-based epoxy resins and low-VOC formulations.

Analysts’ Viewpoint on Epoxy Resins Market Scenario

The epoxy resins market is witnessing steady and broad-based growth, anchored in the material’s exceptional versatility, durability, and adhesion properties. Its extensive use across critical industries—including wind energy, automotive, aerospace, electronics, and construction—is a reflection of its superior mechanical strength, chemical resistance, and bonding performance.

Epoxy resins serve as an indispensable material for a wide range of applications: turbine blades for wind farms, coatings for corrosion protection, adhesives in construction, encapsulants in electronics, and lightweight composites for automobiles and aircraft.

Moreover, environmental regulations and sustainability goals are influencing production and innovation strategies. Leading companies are channeling investment into R&D to create greener, bio-based epoxy systems that maintain performance while minimizing carbon footprint. The focus on waterborne systems, rapid-curing formulations, and high-temperature-resistant products is opening up new opportunities for application-specific advancements.

Market Overview

Epoxy resins are thermosetting polymers formed through the reaction between epoxide compounds and curing agents (often amines). Once cured, they form a rigid, cross-linked polymer with excellent mechanical and adhesive strength, chemical stability, and electrical insulation properties.

Because of these attributes, epoxy resins have become a go-to material across multiple industries. In construction, they’re used in floor coatings, adhesives, repair materials, and waterproofing systems. In electronics, they function as insulating and encapsulating agents for circuit boards. Meanwhile, in aerospace and automotive sectors, epoxy resins form part of lightweight composite materials that enhance fuel efficiency without compromising structural integrity.

The versatility and adaptability of epoxy resins have positioned them as a core material in the global shift toward durable, sustainable, and high-performance industrial solutions.

Key Market Drivers

1. Growing Demand from the Construction Industry

The construction sector remains one of the primary drivers of epoxy resin consumption. As global urbanization and infrastructure development continue at pace—especially in Asia, the Middle East, and Latin America—epoxy resins are gaining prominence for their role in adhesives, coatings, flooring systems, and repair compounds.

Their superior adhesion, corrosion resistance, and durability make them vital for modern infrastructure projects, particularly those that require resistance to harsh environments. From bridges and roads to skyscrapers and industrial facilities, epoxy-based coatings protect structural surfaces against chemical exposure, moisture, and weathering.

Furthermore, the push toward sustainability in construction is fostering demand for bio-based and low-VOC epoxy systems, aligning with green building certifications and environmental regulations. As construction materials evolve toward longer lifespans and eco-friendly formulations, epoxy resins will continue to play a central role.

2. Expansion in Automotive and Aerospace Industries

The global shift toward lightweight materials to improve energy efficiency and reduce emissions has significantly boosted the use of epoxy resins in automotive and aerospace manufacturing.

In the automotive industry, epoxy resins are integral to carbon fiber composites used in body panels, chassis components, and interior parts. These materials reduce vehicle weight while enhancing safety, strength, and resistance to environmental degradation. With the rising production of electric vehicles (EVs), epoxy resins are gaining further traction due to their role in producing lightweight, thermally stable, and corrosion-resistant components, which enhance battery life and efficiency.

Similarly, the aerospace sector relies on epoxy resins for structural bonding, laminates, and coatings that can withstand extreme stress, temperature, and chemical conditions. As next-generation aircraft and space vehicles demand more advanced materials, epoxy composites will remain vital for achieving performance and safety benchmarks.

3. Paints & Coatings: Leading Application Segment

Among various applications, paints and coatings dominate the epoxy resins market. These coatings are widely used across industrial, automotive, marine, and infrastructure sectors for their outstanding adhesion, mechanical strength, and resistance to chemicals and abrasion.

Epoxy-based coatings provide long-term protection to substrates such as metal, concrete, and plastic, extending equipment life and maintaining structural integrity. In the marine industry, for example, they act as a barrier against saltwater corrosion, while in industrial environments, they safeguard machinery and flooring against wear and chemical damage.

In construction, epoxy floor coatings not only enhance durability but also improve aesthetics, making them popular in commercial complexes, factories, and hospitals.

Regional Outlook

Asia-Pacific Leads Global Market Growth

The Asia-Pacific region currently holds the largest share of the global epoxy resins market and is expected to maintain its dominance through 2035. Rapid industrialization, urbanization, and economic growth in countries such as China, India, Indonesia, and South Korea are fueling demand across construction, automotive, and electronics sectors.

China remains the epicenter of production and consumption, with massive infrastructure projects and a booming EV market driving epoxy resin utilization. India’s “Make in India” initiative and its growing construction industry are further expanding regional demand.

Moreover, environmental awareness and regulatory standards in Asia-Pacific are encouraging the adoption of eco-friendly epoxy formulations, spurring innovation among regional manufacturers to develop low-VOC and bio-based resins tailored to local requirements.

Competitive Landscape

The epoxy resins industry features a mix of global giants and emerging regional manufacturers, all vying for market share through technological innovation, capacity expansion, and strategic collaboration.

Key players include:

- Huntsman Corporation

- BASF SE

- Dow Inc.

- Hexion Inc.

- Momentive Performance Materials

- Solvay SA

- Aditya Birla Chemicals

- Kukdo Chemicals Co. Ltd.

- Olin Corporation

- Nan Ya Plastics Corporation

These companies are actively investing in sustainable chemistry, emphasizing bio-based resins, solvent-free systems, and advanced curing technologies. At the same time, regional players in Asia-Pacific—especially in China and India—are capitalizing on local cost advantages and supply chain efficiencies to cater to domestic markets.

Recent Key Developments

- February 2024 – DCM Shriram Ltd. announced a major investment exceeding US$ 10 billion to establish a greenfield plant for advanced materials production, including liquid epoxy resins, hardeners, and reactive diluents. The initiative aims to meet growing demand from electronics, wind energy, EV, and fireproofing sectors.

- April 2024 – Westlake Corporation introduced a new line of low-yellowing epoxy resins, targeting performance-driven sectors like automotive, electronics, and construction, where color stability and high endurance are critical.

These developments underscore a strategic shift toward high-performance, environmentally responsible epoxy systems, reflecting broader global trends in material innovation.

Future Outlook

Looking ahead, the epoxy resins market through 2035 will be characterized by a strong push toward sustainability, performance optimization, and technological advancement. The convergence of green chemistry, renewable energy projects, and lightweight mobility solutions will define the next phase of growth.

Emerging trends include:

- Greater adoption of bio-based raw materials and recyclable epoxy systems.

- Integration of nanotechnology to enhance thermal, electrical, and mechanical properties.

- Rising demand for customized formulations tailored to specific industrial needs.

- Expansion of epoxy applications in wind turbine manufacturing, smart electronics, and 3D printing materials.

The increasing synergy between material science, environmental policy, and industrial innovation positions epoxy resins as a strategic enabler of sustainable industrial growth.

Conclusion

The global epoxy resins market stands on the brink of a transformative decade. Backed by robust demand across construction, transportation, and electronics, and propelled by the drive for eco-friendly, high-performance materials, the market is set to achieve steady and resilient growth.

As key industry players continue to innovate and adapt to environmental and technological challenges, epoxy resins are expected to remain a cornerstone of modern industrial development, bridging the gap between durability, efficiency, and sustainability in the materials landscape.

By 2035, the market’s expansion to US$ 23.5 billion will mark not only an increase in value but also a leap forward in greener, smarter material solutions shaping the future of global industries.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness