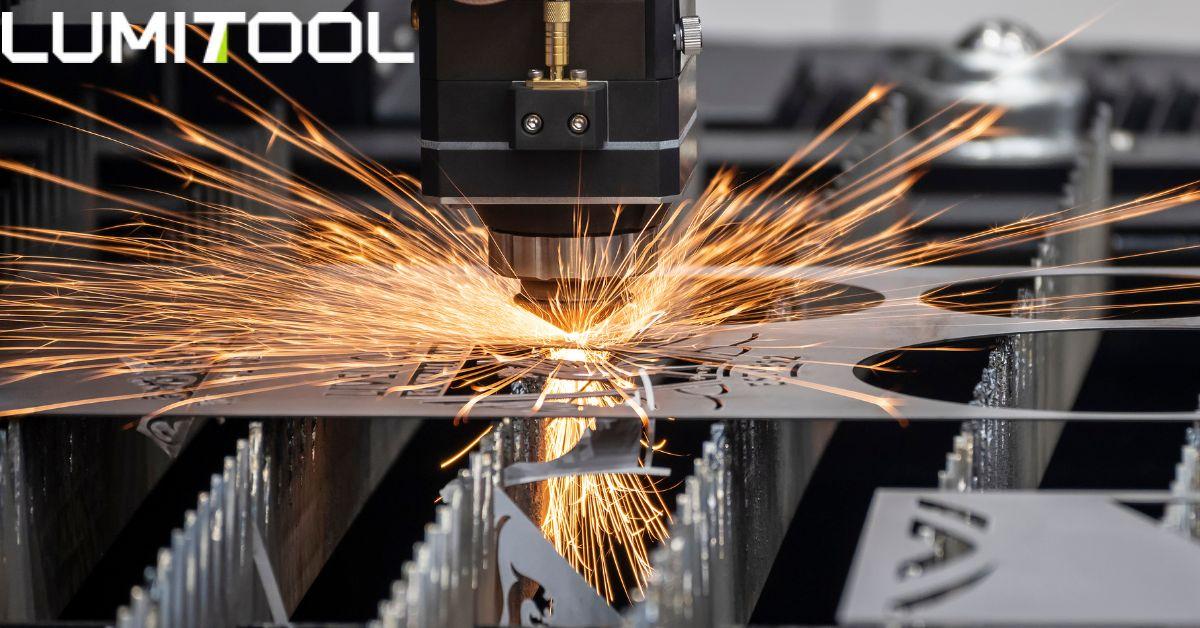

Revolutionize Product Identification with Precision fiber laser marking

In today’s fast-paced industrial landscape, precision, durability, and efficiency are key to maintaining a competitive edge. The rise of fiber laser marking technology has transformed the way manufacturers and businesses handle product labeling, identification, and branding. Combining cutting-edge optics and advanced laser engineering, this technology delivers high-performance results with minimal maintenance and maximum reliability.

What Is Fiber Laser Marking?

Fiber laser marking is a process that uses a focused laser beam to create permanent, high-contrast marks on a wide range of materials—such as metals, plastics, ceramics, and coated surfaces. Unlike traditional marking methods that rely on inks or mechanical contact, fiber laser technology uses non-contact, high-speed energy transfer to create detailed, indelible marks that resist wear, heat, and corrosion.

This makes it an ideal solution for industries that demand precision and longevity in marking, such as aerospace, automotive, electronics, jewelry, and medical manufacturing.

Key Advantages of Fiber Laser Marking

The benefits of fiber laser marking extend far beyond traditional engraving techniques. Some of the standout advantages include:

-

Unmatched Accuracy: The focused beam ensures micro-level precision for even the most intricate designs.

-

High Speed: The system operates at impressive speeds, enabling mass production without sacrificing detail or consistency.

-

Eco-Friendly Operation: No need for inks, chemicals, or consumables—making it both cost-efficient and environmentally responsible.

-

Minimal Maintenance: With a long operational lifespan, the fiber laser system reduces downtime and maintenance costs.

-

Versatility: Works efficiently on metals, plastics, and even reflective materials.

Applications Across Industries

From product traceability to aesthetic branding, fiber laser marking serves countless applications. Manufacturers use it to etch serial numbers, barcodes, and QR codes for product tracking and compliance. Meanwhile, luxury brands and designers employ it for decorative markings on jewelry, watches, and premium goods.

The technology’s precision and consistency make it especially valuable in regulated industries where readability and permanence are essential—such as medical device marking and aerospace component labeling.

Why Choose Lumitool Fiber Laser Marking Systems?

Lumitool’s advanced fiber laser marking systems are engineered to meet the demands of modern manufacturing. Designed with intelligent software integration, ergonomic usability, and automation compatibility, these machines deliver exceptional marking quality while improving production efficiency.

Lumitool prioritizes precision, performance, and innovation, offering durable systems that require minimal upkeep while maintaining world-class output standards. Whether you’re a small workshop or a large-scale production facility, Lumitool provides scalable solutions to elevate your marking and branding capabilities.

Final Thoughts

Incorporating fiber laser marking technology into your workflow isn’t just an upgrade—it’s a strategic step toward efficiency, sustainability, and precision. It ensures every product you create carries a mark of quality that lasts a lifetime.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness