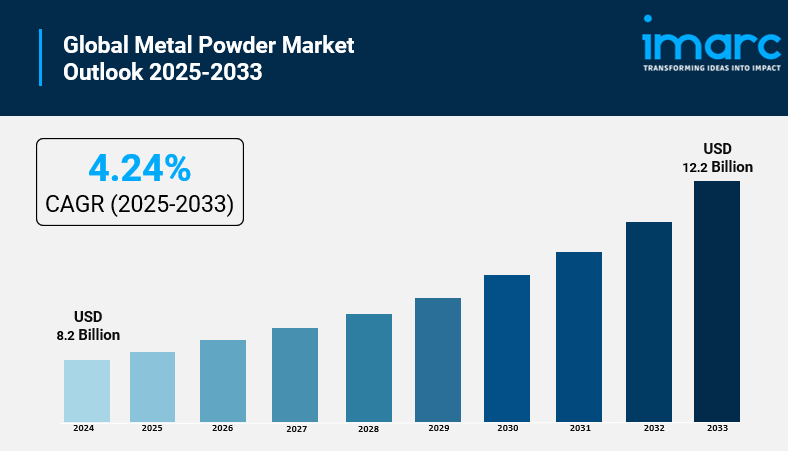

Metal Powder Market Size is Estimated to Reach USD 12.2 Billion by 2033

IMARC Group, a leading market research company, has recently released a report titled “Metal Powder Market Size, Share, Trends and Forecast by Material, Technology, Application, and Region, 2025-2033”. The study provides a detailed analysis of the industry, including the metal powder market size by country, growth, size, and industry growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How Big Is the global metal powder market?

The global metal powder market size reached USD 8.2 Billion in 2024. The market is projected to reach USD 12.2 Billion by 2033, exhibiting a growth rate (CAGR) of 4.24% during 2025-2033.

Growing Adoption in Additive Manufacturing

The growth of the metal powder market is the main attraction to the rising popularity of additive manufacturing. Additive manufacturing, especially 3D printing, has become more and more common in a wide range of industrial sectors, and daily metal powders are emerging as the primary raw materials needed to supply high-precision parts for aerospace, automotive, healthcare, and industrial applications. The need for lightweight, strong, and complex metal components is expected to be the main driver of metal powder usage in additive manufacturing through 2025. Besides, the manufacturers are utilizing metal powders for the production of the components to be customized in drastically decreasing their lead times, getting cost savings and generating very little wastage of material. Recent innovation that has come about in instance like selective laser melting as well as electron beam thermal cutting have been associated with a great deal of reliance on the materials used in the various metal powder segments hence are becoming more prominent. The whole approach of integrating metal powders into current usage of the factory enables the company to provide them with the performance of the product as well as the fulfillment of the various strict specifications of the industry. As this trend continues, the trajectory for the metal powder business is clearly heading upwards, as more and more industrial requirements for this material, the coming up of new powder combinations, and wider use of 3D printing applications will be the driving forces behind this evolution. This reality shows a close tie between the increase of additive manufacturing and the buzz for metal powders all across the globe.

Increasing Demand from Automotive and Aerospace Sectors

The automotive and aerospace industries are the main sources of the expansion of the metal powder market. They are expected to lead the demand in 2025 for high strength, low weight, and corrosion-resistant components. Metal powders are enabling manufacturers to deliver the closest to perfection parts like gears, engine parts, and the structural elements, which are the essential factors that can make the combination of safety, performance, and fuel efficiency possible. The trend of electric vehicles and advanced aerospace designs has led companies to raise their demands for specific powders such as aluminum, titanium, and stainless steel. These companies are gunning for technological progress, as well as the production of powders with improved particle size distribution, and pit compositions that will truly meet the industrial standards of the future. Pulverized metals, for example, will let manufacturers use the weight-to-strength ratio to their advantage, thus substantially reducing waste and giving them the possibility to create such complicated shapes that traditional manufacturing techniques just can't handle. The developments of the automotive and aerospace industries which have been steadily happening for some time now, along with the technological progression in the production process, still go a great way in confirming metal powders as the most essential raw materials.

Advancements in Powder Metallurgy and Material Innovation

The metal powder market is affected tremendously by powder metallurgy advancement and material science. In 2025, the development of high-performance alloys, composite powders, and the manufacture of powders that are needed for the world's most extreme industrial applications, will likely follow the markets' needs. Powder metallurgy provides the option of safely and precisely controlling the aspects of materials, which include but not limited to: density, hardness, and heat resistance; all very necessary for the production of durable and energy-efficient components. Atomization, mechanization of alloys, and sintering have become the main innovations that have improved powder quality while at the same time reduced production costs. They, therefore, become strong motivators for the adoption of the powders from certain industries. Besides this, there is a conscious push of industries to use powders that fully meet the environmental goals and even regulatory requirements to apply the technology. These developments do a lot to broaden the use of metal powders and also ensure product reliability and performance in various sectors such as automotive, aerospace, medical, and electronics. As research and technological breakthroughs move forward, the metal powder market is getting richer in terms of product variety and material efficiency thus leading to an upsurge of demand in global manufacturing landscapes.

Metal Powder Market Trends 2025

The metal powder market is experiencing a major shift in trends that are causing the industry and materials market landscape to change quite a bit. Industrial production lines of 3D printing and additive manufacturing are becoming increasingly prevalent and thus the need for powders of high quality and that are customizable is also growing in 2025. Manufacturers are moving into new advanced alloy powder areas such as titanium and nickel to be able to meet the tough requirements of the aerospace, automotive, and medical components. Metal powder companies are going to be more and more aware of the environment and will be increasingly focusing on it by creating ecometal powders that will hardly have an impact on the environment. Moreover, digitalization and automation of the powder production and quality control are resulting in the general performance being enhanced as well as the size distribution of the particles getting improved and the consistency of the particles getting better. One of the powder manufacturers and industrial players is that collaborations are one of the keys to opening the application volume and coallowing stage next-generation components to be designed. Large-scale industrialization with subsequent market entry is one of the industrialization trends that lead to a rise in the metal powder consumption. The market trend of manufacturing lightweight, durable, and high-precision parts is still growing, and metal powders are becoming one of the indispensable raw materials of the process.

Get your Sample of Metal Powder Market Insights for Free: https://www.imarcgroup.com/metal-powder-market/requestsample

Industry Segmentation:

Material Insights:

- Ferrous

- Non-Ferrous

Technology Insights:

- Pressing and Sintering

- Metal Injection Molding

- Additive Manufacturing

- Others

Application Insights:

- Automotive

- Aerospace and Defense

- Healthcare

- Others

Regional Insights:

- North America

- Europe

- Asia Pacific

- Middle East and Africa

- Latin America

Who are the key players operating in the industry?

The report covers the major market players including:

- Advanced Technology & Materials Co., Ltd.

- ATI Inc.

- Carpenter Additive (Carpenter Technology Corporation)

- Continuum Powders

- GKN Powder Metallurgy

- H.C. Starck Tungsten GmbH

- Höganäs AB

- JSC POLEMA

- Kymera International

- Linde PLC

- Rio Tinto

- Sandvik AB

Ask Our Expert & Browse Full Report with TOC & List of Figure: https://www.imarcgroup.com/request?type=report&id=3721&flag=E

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness