What Should You Consider When Choosing an Angle Grinder Hole Saw?

An Angle Grinder Hole Saw is a versatile cutting tool designed for creating precise circular holes in various materials, including metal, wood, plastic, and masonry. By combining the rotary power of an angle grinder with the specialized design of a hole saw, this tool provides efficient and accurate cutting for both industrial and DIY applications. Professionals in construction, fabrication, and maintenance rely on the Angle Grinder Hole Saw for tasks that require speed, precision, and adaptability.

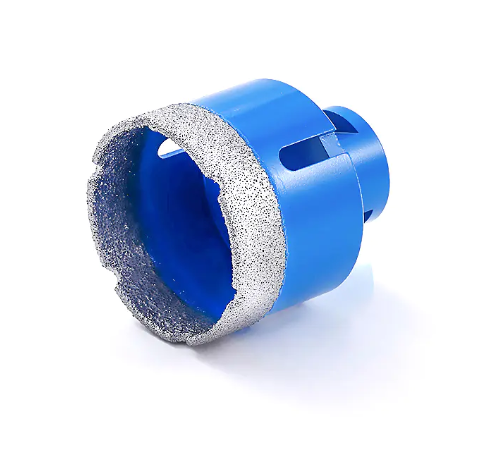

The main advantage of an Angle Grinder Hole Saw is its ability to cut through thick and hard materials efficiently. The teeth or cutting edges of the hole saw are often made of hardened steel, tungsten carbide, or diamond-coated materials, allowing the tool to handle demanding applications. Choosing the right Angle Grinder Hole Saw depends on the material type and desired hole size. Many manufacturers produce multiple diameters and styles to accommodate different project requirements.

Compatibility and safety are key considerations. An Angle Grinder Hole Saw is designed to be mounted securely on the arbor of a standard angle grinder, ensuring stable operation and minimizing the risk of slippage. Safety features, such as protective guards and proper clamping mechanisms, reduce the chance of accidents during high-speed cutting. Users are advised to wear appropriate personal protective equipment, such as gloves and eye protection, when operating an Angle Grinder Hole Saw.

Durability and precision are also important. A quality Angle Grinder Hole Saw is manufactured with precise tolerances and robust materials to maintain performance under repeated use. Heat-treated edges and reinforced construction help prevent premature wear, maintaining sharpness and cutting efficiency. By choosing a reliable Angle Grinder Hole Saw, users can achieve accurate holes without excessive effort or frequent tool replacement.

Versatility is another significant feature. Angle Grinder Hole Saws are suitable for a wide range of applications, from plumbing installations and electrical work to furniture making and metal fabrication. Some models include adjustable depth stops or pilot bits for controlled and guided cutting. This adaptability makes the Angle Grinder Hole Saw a practical choice for both professional tradespeople and hobbyists.

Efficiency is enhanced by the high-speed rotation of the angle grinder. The combined power allows the Angle Grinder Hole Saw to cut quickly, reducing labor time while producing clean edges. Proper use of the tool minimizes material damage and ensures a smooth finish, which is especially important in applications requiring precise hole dimensions.

Maintenance is another aspect to consider. Keeping the Angle Grinder Hole Saw clean, lubricated, and free from debris helps maintain cutting performance and extends its service life. Users should inspect the teeth or cutting edges regularly and replace worn components as needed to ensure consistent results.

Economic and practical value is a further advantage. By investing in a durable and compatible Angle Grinder Hole Saw, users reduce downtime, minimize material waste, and achieve reliable results across multiple projects. The versatility and durability of the tool make it a cost-effective addition to a workshop or job site.

An Angle Grinder Hole Saw is an essential tool for creating precise, clean holes in a variety of materials. Its combination of cutting power, precision, versatility, and durability makes it valuable for construction, fabrication, and repair tasks. Selecting a quality Angle Grinder Hole Saw ensures efficiency, safety, and long-term performance, supporting professionals and DIY enthusiasts in achieving accurate and reliable results.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Musik

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness