Color Coated vs Anodized Aluminum Circle: Color Fastness for Cookware

Posted 2025-09-23 06:34:40

0

2K

Color fastness is a non-negotiable factor for cookware aluminum circles—consumers demand cookware that retains its appearance despite high heat, frequent cleaning, and food contact. Two common surface treatments for cookware aluminum circles, color coating and anodization, differ significantly in color fastness performance. Below is a detailed comparison to help you understand their strengths, weaknesses, and suitability for cookware applications.

1. What Are Color Coated and Anodized Aluminum Circles?

Before diving into color fastness, it’s critical to clarify the two treatments’ basics, as their processes directly impact performance.

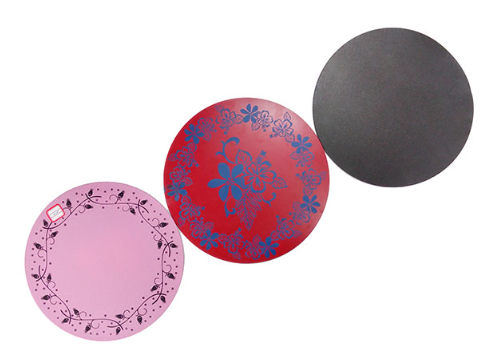

- Color Coated Aluminum Circles: A layer of polymer-based coating (e.g., polyester, epoxy) is applied to the aluminum circle’s surface via spraying or rolling, then cured at high temperatures. The coating adds color and a protective film, with customizable hues for cookware designs.

- Anodized Aluminum Circles: The aluminum circle undergoes an electrochemical process (anodization) that creates a porous oxide layer (alumina) on its surface. Color is then infused into these pores—either via dyeing the oxide layer or using colored electrolytes—resulting in a integrated, matte or semi-gloss finish.

2. Color Fastness Under Cookware’s Core Stressors

Cookware faces repeated exposure to heat, water, detergents, and physical friction—all of which test color retention. Here’s how the two treatments perform:

Heat Resistance: Anodized Gains an Edge

Cookware aluminum circles endure temperatures up to 200–250°C (392–482°F) during cooking.

- Anodized Aluminum Circles: The oxide layer is heat-stable; its infused color bonds tightly with the aluminum substrate. Even under prolonged high heat (e.g., searing meat), it rarely fades, discolors, or peels—ideal for stovetop cookware like frying pans.

- Color Coated Aluminum Circles: Polymer coatings have lower heat tolerance. While high-quality coatings (e.g., ceramic-reinforced types) can withstand 180–220°C, exceeding this range may cause the coating to yellow, blister, or lose color. They’re better suited for low-heat cookware (e.g., saucepans) or exterior decorative parts.

Chemical Resistance: Both Perform Well, With Caveats

Frequent cleaning with detergents (including acidic/alkaline ones) challenges color stability.

- Anodized Aluminum Circles: The dense oxide layer repels most detergents. Dyes used in anodization (especially inorganic ones) resist fading from soap, vinegar, or citrus-based cleaners—no color leaching occurs even with daily use.

- Color Coated Aluminum Circles: Quality coatings (e.g., food-grade epoxy) are also chemical-resistant, but low-quality coatings may degrade over time. Harsh abrasives or prolonged soaking in strong detergents can strip the coating, exposing the aluminum and fading the color.

Abrasion Resistance: Anodized Stands Tougher

Cookware surfaces (e.g., pot bottoms, pan interiors) face friction from utensils or scrubbers.

- Anodized Aluminum Circles: The hard oxide layer (Mohs hardness 6–7) resists scratches from metal utensils. Scratches rarely affect color, as the dye is embedded in the oxide layer, not just a surface film.

- Color Coated Aluminum Circles: The polymer coating (Mohs hardness 2–3) is softer. Scratching with metal spatulas or abrasive sponges can remove small coating flakes, revealing the aluminum underneath and creating uneven color patches.

3. Suitability for Different Cookware Types

Based on color fastness, each treatment fits specific cookware needs:

- Anodized Aluminum Circles: Best for high-wear, high-heat cookware—such as frying pans, woks, and Dutch ovens—where long-term color retention and durability are priorities. Their matte finish also hides minor scratches well.

- Color Coated Aluminum Circles: Ideal for low-heat cookware (e.g., soup pots) or cookware exteriors, where aesthetic variety (bright colors, patterns) matters more than extreme heat/abrasion resistance. They’re also more cost-effective for mass-produced, budget-friendly cookware.

Conclusion

For cookware, anodized aluminum circles excel in color fastness under heat, chemicals, and abrasion, while color coated options offer flexibility in design at a lower cost—your choice depends on cookware type and performance needs. For top-tier color coated aluminum circles that balance vibrant, long-lasting color with food-grade safety and cookware-specific durability, choose Lanren Aluminum’s color coated aluminum circle.

Site içinde arama yapın

Kategoriler

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Cómo Completar los Icon SBC en EA FC 25: Mejores y Peores Jugadores

Los Icon SBC en EA Sports FC 25 brindan a los jugadores la oportunidad de añadir algunas...

Solar PV Mounting Systems Market 2031: Emerging Trends, Analysis, and Overview

United States of America – 17 Oct 2025

The Insight Partners is proud to announce its...

Ultimate Guide to Buying Coins FIFA: Maximize Your FC 26 Coin Experience

Ultimate Guide to Buying Coins FIFA: Maximize Your FC 26 Coin Experience

Welcome to the dynamic...

Military Power Solutions Market Size Outlook of Leading Companies By (2024-2032)

Military Power Solutions Market Outlook

The global Military Power Solutions Market is projected...

Crediti FC 25: Acquista i Crediti FC25 al Miglior Prezzo!

Crediti FC 25: Acquista i Crediti FC25 al Miglior Prezzo!

Quando si tratta di Crediti FC 25,...

© 2026 Scenario.press - libera espressione

Turkish

Turkish