Permanent Magnetic Chuck Might Affect High-Accuracy Metalworking Operations

Precision Machining and Magnetic Fields

Permanent Magnetic Chuck devices are widely used to securely hold ferromagnetic workpieces during machining. While their strong magnetic field ensures stable adhesion, concerns arise about whether this magnetic field could interfere with high-precision operations. Understanding the potential for magnetic interference is essential to maintain machining accuracy and prevent damage to sensitive tools or equipment.

Magnetic Field Distribution and Intensity

The magnetic field generated by a Permanent Magnetic Chuck is generally concentrated near its surface, creating a strong holding force on ferromagnetic workpieces. For most machining tasks, this field does not extend far enough to interfere with surrounding electronics or precision instruments. However, in applications requiring extreme measurement accuracy, even minor magnetic influences could potentially affect sensitive sensors or digital readouts.

Factors Influencing Magnetic Interference

Several factors determine whether a Permanent Magnetic Chuck produces noticeable interference. The size and strength of the magnets, the distance between the chuck and sensitive equipment, and the material properties of the workpiece all play a role. Thicker or more permeable workpieces tend to contain the magnetic field within the material, reducing stray fields that could affect nearby instruments.

Design Considerations for Minimizing Effects

Manufacturers mitigate potential magnetic interference through careful design. Permanent Magnetic Chuck units often incorporate shielding, optimized magnet layouts, and controlled magnetic circuits to focus the field on the workpiece. These measures ensure that the magnetic flux is concentrated where needed, minimizing stray fields that could influence high-precision machinery.

Practical Recommendations for Operators

To maintain accuracy during precision machining, operators should position sensitive instruments at a safe distance from the magnetic chuck. Regular monitoring of tool calibration and ensuring proper workpiece placement further reduces the risk of magnetic effects. Selecting a chuck with verified shielding and quality construction also helps preserve both machining precision and operational safety.

Magnetic Chuck Use in Precision Applications

In conclusion, while Permanent Magnetic Chuck devices produce strong magnetic fields for holding ferromagnetic workpieces, proper design and use minimize interference during high-precision machining. Awareness of magnetic field distribution, appropriate positioning of sensitive equipment, and careful selection of the chuck ensure reliable, accurate, and safe machining operations even in the most demanding environments.

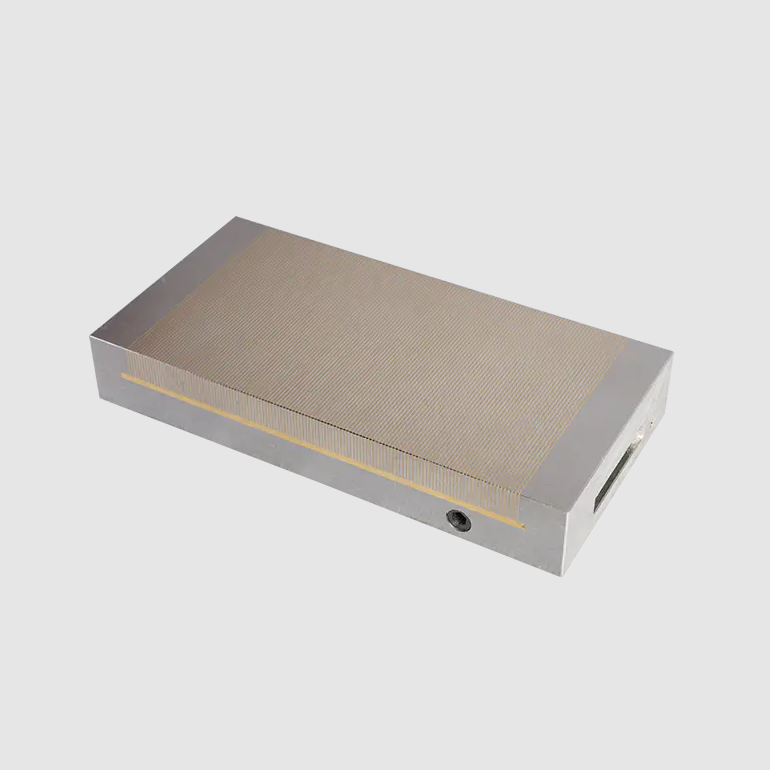

Workholding device designed for secure and stable clamping of ferromagnetic materials during machining processes. Utilizing permanent magnetic technology, this model offers consistent holding force without the need for external power, making it suitable for grinding, milling, and other metalworking operations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness