How Rubber Accelerator Affects Mechanical Properties of Vulcanized Rubber

Role of Rubber Accelerator in Vulcanization

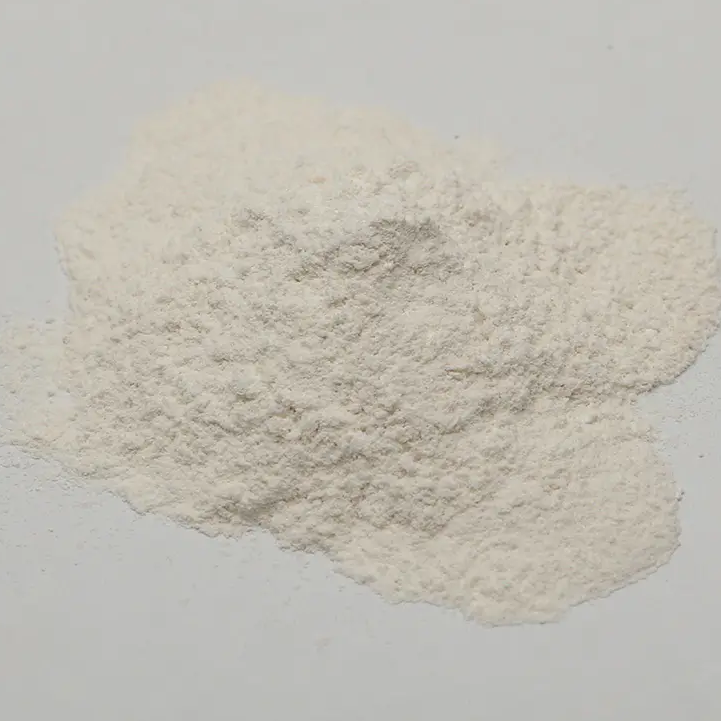

Rubber Accelerator is a vital component in rubber processing, controlling the curing rate and crosslinking density during vulcanization. Its effect is not limited to reaction speed; it can also influence the mechanical properties of the final product. Understanding how Rubber Accelerator impacts hardness, elasticity, and flexibility is crucial for producing rubber that meets specific performance requirements.

Impact on Hardness

The type and concentration of Rubber Accelerator directly affect the hardness of vulcanized rubber. Accelerators that promote faster or more extensive crosslinking tend to increase hardness by creating a denser network of molecular bonds. Conversely, slower-acting accelerators or lower dosages may result in softer rubber with reduced rigidity. Selecting the appropriate accelerator allows manufacturers to control the material’s hardness to meet design specifications.

Effect on Elasticity and Flexibility

Rubber Accelerator also influences the elasticity and flexibility of rubber products. High crosslink density achieved with certain accelerators can reduce elasticity, making the rubber less flexible under mechanical stress. On the other hand, carefully balanced formulations with compatible accelerators maintain both adequate hardness and desirable elasticity, ensuring that the rubber can withstand repeated deformation without permanent set.

Interactions With Formulation Components

Other additives, such as fillers, plasticizers, and stabilizers, interact with the Rubber Accelerator and can further modify the mechanical properties. For example, high filler content may enhance hardness while decreasing elasticity, and plasticizers may counterbalance this effect. Understanding these interactions helps optimize the combined influence of Rubber Accelerator and other components on the final rubber properties.

Industrial Implications

Controlling hardness and elasticity is essential for various applications, from tires and seals to flexible hoses and gaskets. Selecting the right type and amount of Rubber Accelerator ensures consistent mechanical performance, reduces defects, and allows manufacturers to tailor rubber products to specific operational requirements. Improper selection can lead to rubber that is either too brittle or insufficiently resilient, compromising product durability and safety.

Optimizing Rubber Properties With Rubber Accelerator

Rubber Accelerator significantly influences the hardness and elasticity of vulcanized rubber through its effect on crosslink density and curing behavior. By understanding the interactions between accelerator type, concentration, and formulation components, manufacturers can achieve the desired balance of rigidity and flexibility. Proper selection and control of Rubber Accelerator ensure consistent product quality and performance across a wide range of industrial applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness