How Three Plunger High Pressure Pump Performs Across Different Liquid Media

Importance of Fluid Compatibility

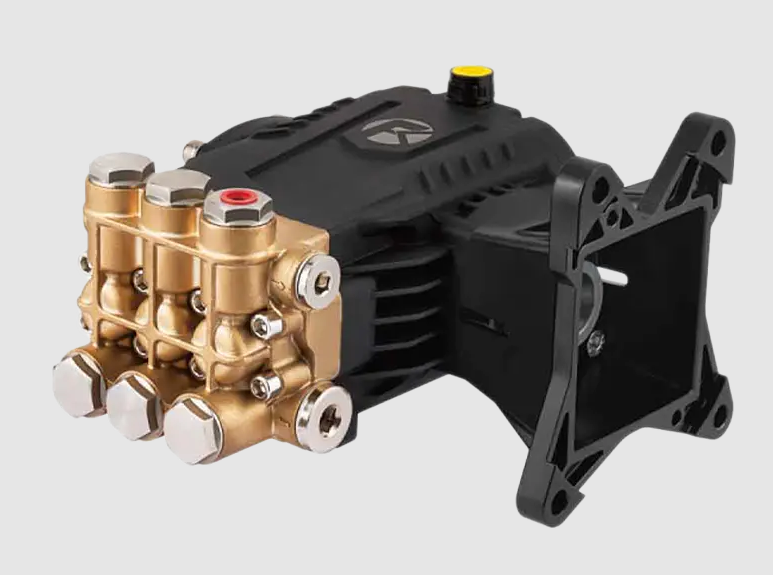

Three Plunger High Pressure Pump is widely used in industrial and commercial applications for high-pressure fluid delivery. A crucial factor for its versatility is whether the pump can handle different types of liquid media, including water, oils, chemicals, and other viscous fluids. Compatibility affects efficiency, durability, and the safety of both the pump and the overall system.

Material Selection and Fluid Resistance

The suitability of a Three Plunger High Pressure Pump for various liquids depends largely on the materials used in its construction. High-quality pumps employ corrosion-resistant metals, chemical-resistant seals, and durable plungers to withstand aggressive or viscous fluids. These material choices ensure that the pump can handle a wide range of media without degradation or leakage, maintaining reliable operation across different applications.

Viscosity and Flow Characteristics

Different liquids have varying viscosities, which can influence the performance of a Three Plunger High Pressure Pump. High-viscosity fluids require more force to move through the pump, whereas low-viscosity fluids may cause higher flow rates but reduce pressure consistency. A well-designed Three Plunger High Pressure Pump can maintain stable output and efficiency across a spectrum of fluid viscosities, ensuring consistent operation in diverse scenarios.

Chemical Compatibility and Safety

Handling chemical fluids requires a Three Plunger High Pressure Pump to resist corrosion and prevent chemical reactions with the pump components. Proper seal and cylinder materials prevent leaks and ensure safe operation. Using the pump with incompatible fluids can lead to damage, reduced lifespan, or even hazardous situations, making chemical compatibility a critical design consideration.

Operational Adjustments for Different Fluids

Operators can optimize a Three Plunger High Pressure Pump for different liquid media by adjusting operational parameters such as pressure, flow rate, and lubrication intervals. Understanding the specific requirements of each fluid type allows for maximum efficiency and longevity, preventing overloading or premature wear.

Versatile Solution for Industrial Applications

Three Plunger High Pressure Pump demonstrates strong adaptability to various liquid media when constructed with suitable materials and operated under proper parameters. Its ability to handle diverse fluids—including water, oils, and chemicals—makes it a versatile and reliable choice for multiple industrial applications. Proper selection, operation, and maintenance ensure long-term performance and efficiency across different fluid types.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness