How Board to Board Power Connector Prevents Wrong Connections and Polarity Errors

Introduction to Safety Considerations

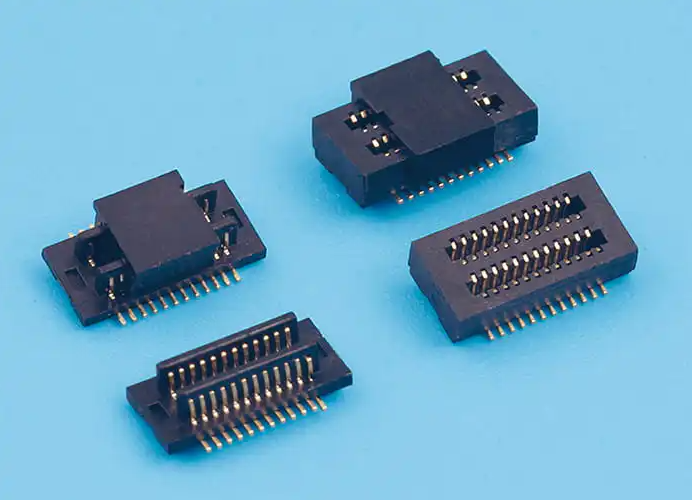

In electronic design, preventing incorrect connections is critical for both safety and device reliability. The Board to Board Power Connector plays an essential role in ensuring that boards are properly aligned and connected. Mis-insertion or reversed polarity can cause system failure, damage components, or even pose a safety risk. Therefore, examining whether the connector includes protective features is crucial for designers and engineers.

Mis-Insertion Prevention Features

High-quality Board to Board Power Connectors often include mechanical keying or asymmetrical designs that prevent improper mating. Lead-in chamfers, notch guides, or offset pins ensure that the connector can only fit in the correct orientation. These features reduce the chance of human error during assembly, making installation faster and more reliable without relying solely on careful attention from operators.

Polarity Protection Design

Polarity protection is particularly important in power connectors to avoid reversing current flow, which could damage sensitive electronics. Board to Board Power Connectors achieve this through specific pin arrangements, keyed contacts, or integrated shunts that prevent connection if polarity is reversed. This design ensures that the power path is maintained correctly, even in high-power applications, providing an added layer of electrical safety.

Practical Applications and Benefits

In practical applications, mis-insertion and polarity protection provide significant advantages. For industrial, automotive, or consumer electronics, these features prevent costly assembly mistakes, reduce system downtime, and protect components from irreversible damage. They also simplify maintenance and upgrades, as operators can connect boards quickly without fear of accidental errors.

Reliability and User Confidence

Connectors with mis-insertion and polarity protection improve system reliability and operator confidence. By minimizing the risk of incorrect connections, these connectors reduce troubleshooting time and maintenance costs. Designers can specify these connectors knowing that both mechanical and electrical safeguards are integrated into the product.

The Board to Board Power Connector often incorporates both mis-insertion prevention and polarity protection through keyed designs, specialized pin arrangements, and guiding features. These safety mechanisms ensure proper board alignment, correct electrical flow, and reliable operation across a range of applications. For engineers and manufacturers, these protective features are invaluable, improving both system reliability and ease of use while preventing potential damage from human error.

1、CKT: 2Pin

2、Current rating: 1A AC/DC

3、Voltage rating(max): 125V, AC/DC

4、Working Temperature: -25°C~+85°C,

(Including temperature rise in applying electrical current)

5、Contact resistance:value s20mΩ

After environmental testing≤30msΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 500VAC(rms)

8、Applicable PCB board thickness: 1.6mm to 2.0mm

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness