Managing Emergencies: Response Strategies for Horizontal Band Saw Machine

Understanding the Importance of Emergency Response

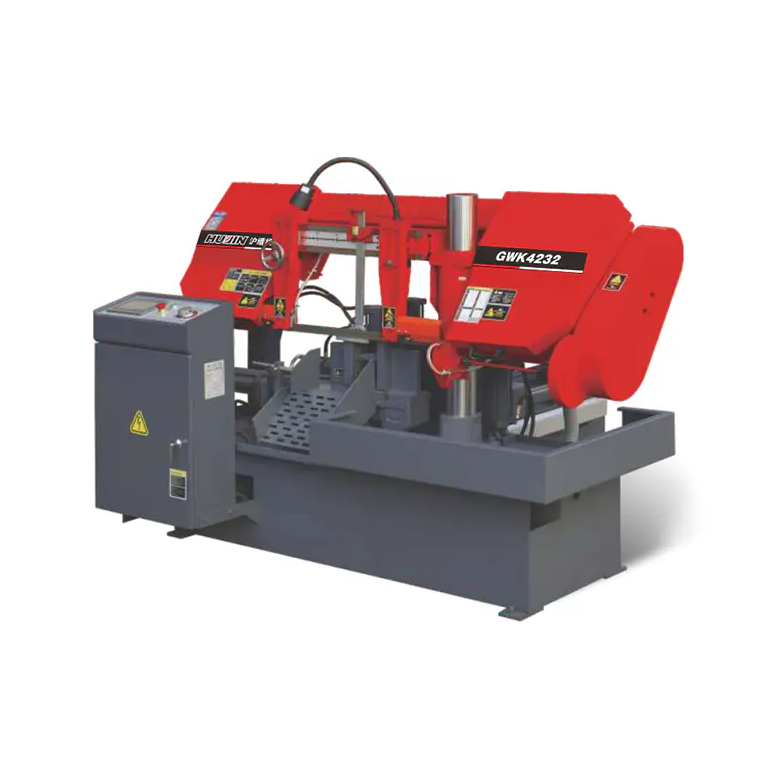

In the realm of industrial machinery, the Horizontal Band Saw Machine is a powerful tool for cutting various materials. However, like any machinery, it can present potential hazards in emergencies. Operators and maintenance staff must be well-versed in emergency response measures to ensure both the safety of personnel and the preservation of equipment.

Identifying Common Emergencies

Common emergencies with the Horizontal Band Saw Machine include power outages, blade breakage, and mechanical failures. Each of these can lead to downtime and potential safety risks. Understanding the specific signs of these emergencies is the first step in implementing effective emergency protocols.

Emergency Response Planning

Preventative measures are the best form of emergency response. Regular maintenance and inspections can mitigate the risk of many emergencies. However, when an unforeseen event occurs, a well-planned response is crucial. This includes immediate shutdown procedures, emergency stop protocols, and safe evacuation routes for personnel.

Blade Breakage and Jamming

In the event of blade breakage or jamming, the Horizontal Band Saw Machine must be shut down immediately to prevent further damage or injury. Operators should be trained to identify the sounds and vibrations that indicate blade issues and to shut down the machine safely without causing additional harm.

Power Outages

Power outages can leave the Horizontal Band Saw Machine in a compromised state. Emergency response measures should include procedures for safely securing the machine and its components to prevent damage during power fluctuations. This may involve manual release mechanisms or backup power systems to safely disengage cutting tools.

Fire and Smoke Emergencies

In case of fire or smoke, the Horizontal Band Saw Machine should be shut down according to emergency protocols, and all personnel should evacuate the area. Fire suppression systems should be in place, and operators should be trained in their use. Regular fire drills and inspections of these systems are essential.

The Horizontal Band Saw Machine, while a valuable asset in metalworking, requires careful management in emergencies. By implementing comprehensive emergency response plans, conducting regular training, and maintaining the machinery, companies can minimize downtime and ensure the safety of their workforce. It is through preparedness and swift action that the risks associated with Horizontal Band Saw Machine emergencies can be effectively managed.

Cutting Capacity(mm) :Round material Φ320/Plate 320x320

Blade speed(m/min): 28,40,51,74

Blade Size(mm):1.1344115

Single feeding travel(mm):500

Motor main output(kw):4

Hydraulic(kw):0.75

Coolant pump(kw):0.09

Machine Size(LxWxH)(mm):200020001500

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness