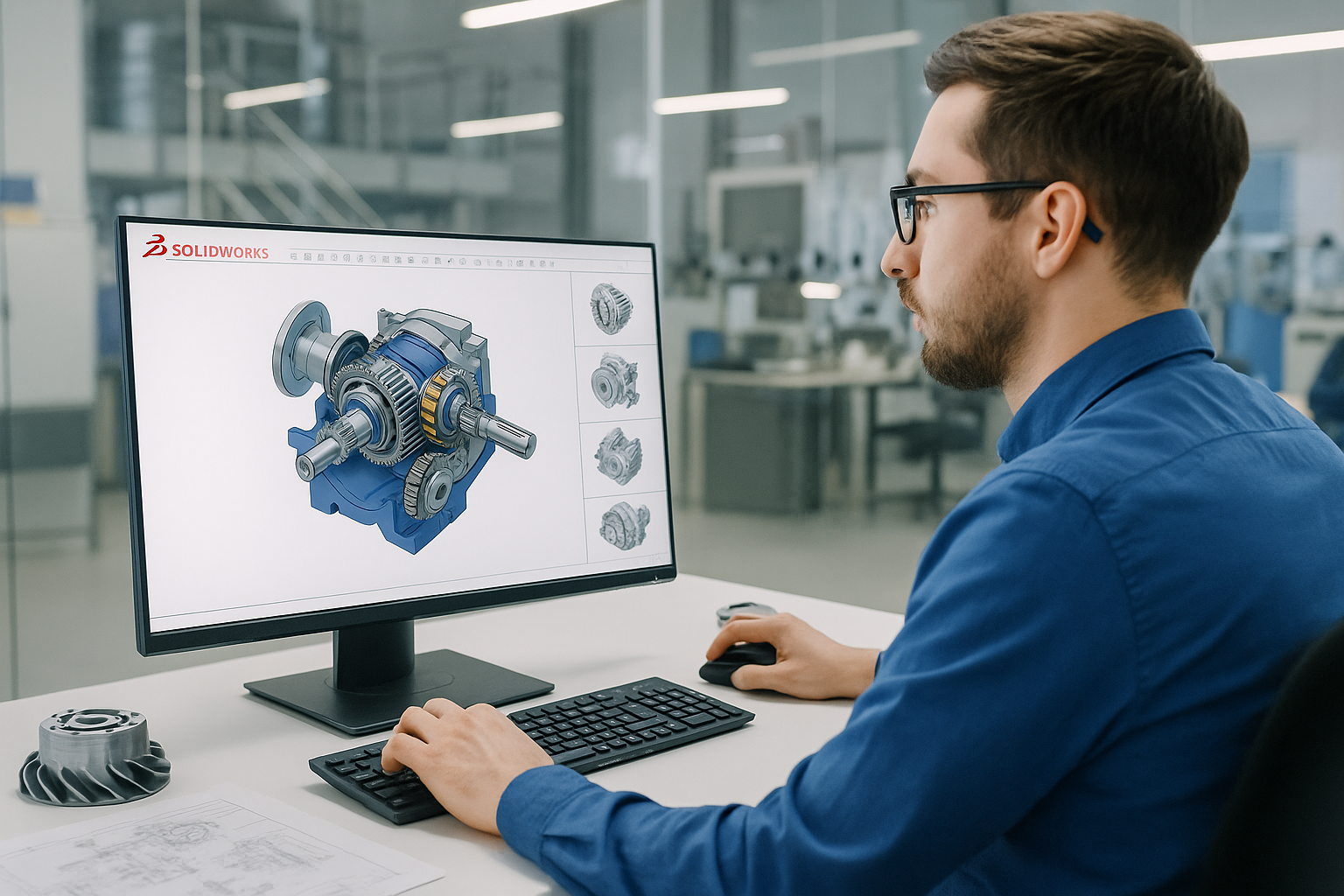

Why Global Brands Choose SolidWorks 3D Modeling Over Other CAD Solutions?

In today’s competitive design and manufacturing landscape, precision, speed, and innovation aren’t just desirable they’re essential. From consumer electronics to automotive engineering, global brands increasingly rely on SolidWorks 3D modeling services to turn ideas into market-ready products faster and with fewer errors.

But why SolidWorks, when so many software for 3D modeling options exist? The answer lies in its unique combination of user-friendliness, advanced simulation features, and cost efficiency. For businesses in the UK and worldwide, SolidWorks has emerged as the go-to 3D product modeling software that delivers consistent results across industries.

Let’s explore the reasons behind this global preference, the key benefits of 3D CAD modeling services, and how it’s reshaping the future of engineering and product design.

What Makes SolidWorks 3D Modeling Stand Out from Other CAD Software?

When it comes to CAD design tools, businesses have plenty of options AutoCAD, CATIA, Fusion 360, and others. However, SolidWorks has carved a niche as the most widely adopted 3D product modeling software in sectors like aerospace, medical devices, consumer goods, and heavy machinery.

Here’s why global brands choose SolidWorks:

-

Ease of Use: SolidWorks is widely known for its intuitive interface, which reduces the learning curve for engineers and designers.

-

Comprehensive Features: From sketching to simulation, SolidWorks offers an end-to-end design-to-manufacturing solution.

-

Parametric Modeling: Changes in one part update across the entire design, cutting down on repetitive tasks.

-

Industry-Wide Adoption: More than 6 million engineers and designers worldwide use SolidWorks (Dassault Systèmes).

-

Integration with CAM/CAE: SolidWorks works seamlessly with analysis and manufacturing software, helping companies shorten production cycles.

This blend of usability and technical power makes it the preferred choice for both startups and multinational enterprises.

How Does SolidWorks Improve Cost Efficiency in Projects?

For any business, reducing design and production costs without sacrificing quality is a top priority. SolidWorks plays a significant role in cost optimization by:

-

Minimizing Rework: With its built-in error detection and simulation tools, SolidWorks helps engineers catch mistakes before manufacturing.

-

Reducing Prototyping Costs: Virtual testing allows companies to avoid expensive physical prototypes.

-

Accelerating Design Cycles: Features like design automation and libraries of standard components save valuable time.

-

Optimizing Material Usage: Simulation tools help determine the best material thickness and geometry, preventing waste.

According to Engineering.com, companies using 3D CAD platforms like SolidWorks can reduce development costs by up to 30% through fewer errors and faster iterations.

Why Do Global Brands Prefer SolidWorks for Complex Projects?

When working on large-scale or high-precision projects, complexity becomes a major challenge. SolidWorks is especially effective in handling:

-

Large Assemblies: Managing thousands of components with smooth navigation.

-

Advanced Simulations: Stress analysis, thermal simulations, and motion studies.

-

Collaborative Workflows: Cloud-based PDM (Product Data Management) ensures teams across the globe can collaborate seamlessly.

-

Customization: SolidWorks API allows custom automation tailored to industry-specific needs.

This adaptability is why industries like automotive and aerospace consistently invest in SolidWorks 3D modeling services instead of alternative tools.

What Role Does SolidWorks Play in Product Innovation?

Innovation is at the heart of modern business success. SolidWorks encourages innovation in several ways:

-

Concept-to-Product Journey: Designers can move from sketches to prototypes in a single environment.

-

Integration with Emerging Tech: SolidWorks supports 3D printing, IoT-ready designs, and digital twins.

-

Enhanced Visualization: Realistic rendering allows stakeholders to visualize the final product early in the design process.

-

Faster Market Entry: By cutting design cycle time, businesses can launch products quicker than competitors.

A survey by Tech-Clarity found that companies using SolidWorks reported a 21% faster time-to-market compared to those using other CAD tools.

How Does SolidWorks Support Global Collaboration?

In today’s interconnected world, design rarely happens in isolation. Multinational companies need tools that support remote collaboration across time zones. SolidWorks delivers by offering:

-

Cloud-Based Access: Teams can work on the same model in real time.

-

Version Control: PDM ensures that every designer is working on the latest version.

-

Cross-Platform Compatibility: SolidWorks files can integrate with other tools, avoiding compatibility issues.

This makes SolidWorks a natural fit for 3D CAD modeling services provided by UK firms that collaborate with partners in the U.S., Europe, and Asia.

What Are the Latest Trends Driving SolidWorks Adoption in 2025?

The CAD industry is evolving rapidly, and SolidWorks continues to adapt to new trends:

-

Sustainability-Driven Design: SolidWorks enables lifecycle analysis to design eco-friendly products.

-

AI Integration: Predictive design suggestions and automation powered by artificial intelligence.

-

Remote Collaboration: A growing shift toward cloud-hosted CAD for hybrid work models.

-

3D Printing: Direct integration with additive manufacturing processes.

-

Augmented Reality (AR) and Virtual Reality (VR): Enhanced visualization for client presentations.

According to Market Research Future, the global CAD market is projected to reach $14.8 billion by 2030, with SolidWorks expected to hold a leading share due to its versatility.

What Challenges Do Businesses Face Without SolidWorks?

Brands that avoid upgrading to advanced CAD solutions often struggle with:

-

High Error Rates: Manual updates in traditional 2D CAD increase the risk of design inconsistencies.

-

Longer Production Cycles: Outdated tools slow down iterations and testing.

-

Higher Costs: More reliance on physical prototypes and material waste.

-

Limited Collaboration: Difficulty sharing files across global teams.

This makes investing in SolidWorks 3D modeling services not just a choice but a necessity for staying competitive.

Key Benefits of Choosing SolidWorks 3D Modeling Services

To summarize, here are the top reasons global brands continue to choose SolidWorks:

-

Faster time-to-market with parametric modeling and automation.

-

Reduced costs through fewer errors and optimized materials.

-

Scalable solutions for startups, SMEs, and global enterprises.

-

Future-ready features with AI, cloud, and sustainability integration.

-

Widespread global support, ensuring consistent adoption worldwide.

Conclusion: The Preferred Path Forward for Global Brands

As industries evolve, the demand for advanced 3D CAD modeling services will only grow. SolidWorks has proven itself as a trusted platform that balances usability, innovation, and cost efficiency.

For startups aiming to accelerate product development and for global brands handling complex, multi-assembly projects, SolidWorks remains the smart investment. While alternative software for 3D modeling tools exist, none have achieved the same level of adoption and reliability across industries.

A leading UK-based CAD design company can provide tailored SolidWorks 3D modeling services that help businesses reduce costs, enhance product innovation, and stay ahead in a competitive global market.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness