How Mobile Impact Crusher Factory Solutions Contribute to Modern Sand and Gravel Operations

Introduction to Aggregate Production Lines

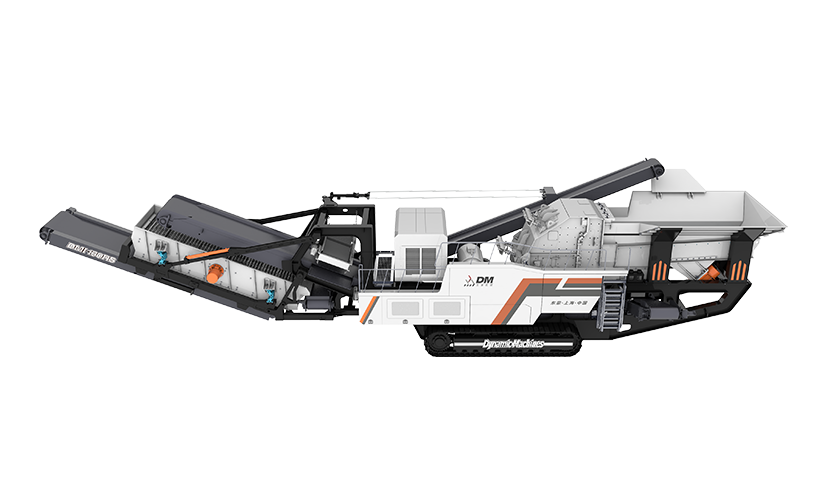

In the development of sand and gravel production lines, efficiency, adaptability, and reliability of equipment are crucial factors. Products from a Mobile Impact Crusher Factory are often integrated into these lines, where their purpose extends beyond simple material reduction. By combining mobility with effective crushing mechanisms, such machines play a significant role in supporting the production of high-quality aggregates required for construction, road building, and other infrastructure projects.

Function in Material Reduction

The primary role of mobile impact crushers in an aggregate line is material reduction. Aggregates such as limestone, granite, and recycled concrete need to be processed into specific sizes to meet industry standards. Impact crushers use high-speed rotors to break down raw materials into smaller, uniform pieces, ensuring that the final product is suitable for further screening or direct application. Their ability to produce well-shaped aggregates makes them particularly valuable for projects where structural integrity and consistency of materials are critical.

Integration with Screening and Conveying Systems

Within a sand and gravel production line, crushing is rarely a stand-alone process. Mobile impact crushers are frequently paired with screening units and conveyor systems, forming a complete processing chain. After initial crushing, materials are directed to vibrating screens that separate different sizes, while conveyors transport the sorted aggregates to storage or further processing stages. The mobility of impact crushers allows them to be repositioned within this chain as needed, offering flexibility that stationary units cannot provide.

Flexibility and On-Site Adaptability

One of the greatest advantages of using mobile impact crushers in aggregate production lies in their adaptability to varying site conditions. Whether the operation is located in a quarry, along a construction site, or within a recycling facility, the equipment can be relocated without requiring extensive foundations or infrastructure. This mobility reduces transportation costs, minimizes delays, and allows operators to respond quickly to changes in project requirements. As a result, aggregate lines become more dynamic and cost-effective.

Contribution to Sustainable Practices

Sustainability is increasingly important in modern aggregate production. Mobile impact crushers contribute to this goal by enabling the processing of recycled materials such as demolished concrete or asphalt. By integrating recycling into the aggregate line, industries can reduce dependence on natural resources while also lowering waste disposal costs. This dual benefit strengthens the environmental and economic value of using mobile impact crushers in contemporary production systems.

A Central Component in Aggregate Processing

The role of mobile impact crushers within sand and gravel production lines is both central and versatile. A Mobile Impact Crusher Factory delivers equipment capable of efficient material reduction, seamless integration with complementary systems, and flexible deployment across diverse sites. Beyond productivity, these machines support sustainability through recycling applications. Their combined contributions make them indispensable in ensuring that aggregate production lines meet the growing demands of the infrastructure and construction industries.

Feed Particle Size: ≤650mm

Processing Capacity: 80-360t/h

Machinery Weight: 45-62t

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness