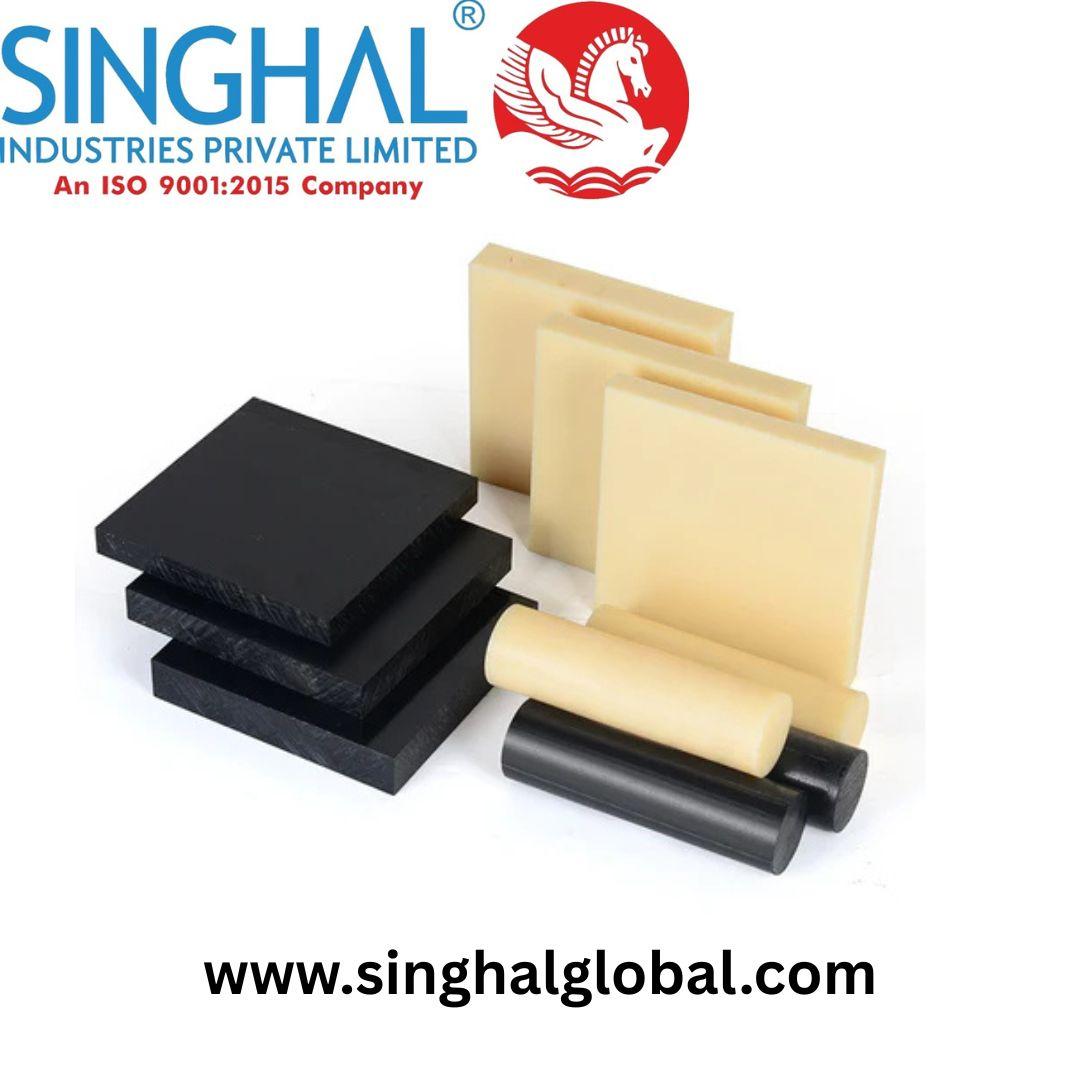

ABS Plastic Sheet – A Versatile Solution for Modern Industries

Introduction to ABS Plastic Sheets

Acrylonitrile Butadiene Styrene, or as commonly known, ABS Plastic has grown to be one of the most flexible and versatile materials in industry. Everything from automotive parts to consumer items can be made from ABS plastic sheet, and it can offer durability, complexity, and a high-quality surface finish. ABS is lightweight but strong, which allows for uses in both industry and household products. The rate of demand for a material like this has steadily increased, especially considering the last few years have brought us many new plastic sheet manufacture in India who are focusing on creativity, eco-friendliness, and affordability.

Properties and Advantages of ABS Plastic Sheets

ABS sheets are recognized as a preferred plastic for several reasons, including their overall balance of strength, impact resistance, and chemical resistance. They also can be easily fabricated, allowing industries to mold the sheets to a variety of shapes and sizes no matter the intended use. 3d wpc wall panel price are superior to other polymers due to the rigidity and toughness associated with their chemically-smooth surface, which is also not prone to scratches. Moreover, ABS sheets can also have a high thermal resistance, adding another level of usability than from other polymers. Further, ABS sheets are available in a variety of thicknesses, colors, and textures, making it easy for designers and engineers to put together various custom applications. Many ABS sheet manufacturers are also adopting environmentally friendly production practices to comply with and adapt to global initiatives for sustainable practices.

Applications of ABS Plastic Sheets Across Industries

ABS plastic sheets are used in various industries, including automotive, construction, packaging, and furniture. They are used in dashboard, trim, and interior panels in the automotive industry because of their high impact resistance. ABS plastic sheets are becoming more common in the construction industry as a substitute for traditional materials. With the current interest in decorative options, ABS sheets are often compared to other products, such as 3D WPC wall panel price, because both ABS sheets and the other option are meeting aesthetic and structural expectations. In addition to that, ABS sheets have extensive uses in electronics, luggage manufacturing, and household products due to their durability and performance.

Market Growth and Trends in ABS Plastic Sheets

The worldwide plastic sheet market is growing steadily which is due in large part to the sizable growth in the use of ABS sheets. The growth in infrastructure projects in India and the dip in the use of heavy materials and the becoming of lighter materials will enhance plastic sheet manufacture in India. The reliability of cost to customize, plus its cost effectiveness continues to position ABS sheets as the premier product both domestically and abroad. The sustainable production processes as well as the recyclable materials used will amplify this growth. Many of the major A B S sheet companies are also focusing on competitive pricing, better quality, and making an exportable product to meet the demands of all regions.

ABS Plastic Sheet vs. Alternatives

While ABS plastic sheets are the preferred material in many industries, it is helpful to understand how they compare to other options including PVC, acrylic, and WPC panels. Many customers look at ABS plastic sheets to compare with the price of 3D WPC wall panels before deciding which product to buy, as they are both aesthetically pleasing. Nevertheless, the reason most customers buy ABS sheet manufacturer is because it has excellent toughness, impact strength, and capacity to handle mechanical stress. Also, ABS sheets provide a more balanced performance than acrylic sheets, which can crack under pressure, for a relatively good price. If you want both performance and good price - ABS sheets are the way to go! To date, many Indian manufacturers have had some measure of success by running better production methods and are voicing concern over fluctuations in production from caused lockdowns and the disruption of supply chains.

Role of ABS Sheet Manufacturers

ABS plastic sheets rely heavily on creativity and skill coming from the manufacturers. An experienced abs sheet manufacturer not only provides quality products, but they are able to offer customized solutions for many industries as well. As extrusion technology advances, the manufacturers of today produce sheets with better finishes, UV resistant, and fire-retardant properties. Plastic sheet manufacturers in India are becoming some of the world leaders in the plastic sheet market, exporting high quality sheets to several different countries. They are able to mass produce products at a high quality level enabling them to stand out from other countries in the world of plastic sheets.

Challenges and Opportunities in the ABS Sheet Industry

Although there is a lot of momentum in the ABS sheet market today, there are challenges that will impact respondents, including raw material swings, environmental compliance, and competition with other polymers. These challenges also represent several strategic opportunities. Specifically, companies investing in research and development will find themselves having to develop new rationales about their ABS sheet manufacturing methods to discover innovatively sustainable and recyclable applications. Organizations are increasingly aware of environmental friendliness and carbon footprints. Therefore, industries must determine how to produce high-performance materials with the lowest carbon footprint possible and sustainable practises. Whoever can balance affordability considerations with quality will be able to varied.

Conclusion

ABS plastic sheets are arguably some of the most trusted and versatile materials used today in industry and home applications. Their unique features, inexpensive cost, and versatile applications in sectors of every description have made them a popular choice. There are many more industries that are looking for sustainable, and high-performance materials and we believe that Plastic sheet manufacturers in india will be significant in the not-so-distant future. With trusted abs sheet manufacturing companies taking a lead, and plastic sheet manufacturers in India expanding abroad, the sky is the limit for growth. You are always assured of value for the money you spend when you compare them against prices other alternatives like 3D WPC wall panel price, or when they are used as stand-alone solutions.

Frequently Asked Questions (FAQs)

1. Where can ABS plastic sheet be used?

ABS plastic sheets are found in automotive interiors, construction, luggage, electronics, furniture, and packaging. ABS plastic sheets provide toughness, impact resistance, and hot-temperature properties for a wide variety of applications.

2. How is it different than other types of sheets?

ABS provides a higher level of impact strength, rigidity, and machinability over materials such as acrylic or PVC, and as such is generally more impact durable and effective in both industrial applications and decorative applications.

3. Is ABS plastic sheet recyclable?

Yes, ABS plastic sheets can be recycled. More and more manufacturers have taken it upon themselves to produce in an eco-friendly manner and ensure that their ABS products fit into the eco-sustainability goals.

4. What are the determining factors in cost of ABS plastic sheets ?

The price will depend on the thickness, surface finish, color, and other properties like UV resistance or flame retardant, plus where ABS sheets are produced will also have an influence on the cost.

5. Why is ABS plastic sheets used in the automotive industry?

They are durable, lightweight, and flexible, which is why they are ideal when used for dashboards, trims, and other structural components of vehicles.

6. Can I get customized ABS sheets?

Yes, ABS sheets can be made in a variety of textures, colors and thicknesses and various industrial and design specifications.

7. Who is the largest supplier of ABS Plastic Sheet?

Singhal Industries Private Limited is the largest supplier of ABS Plastic Sheet and provides world-class quality and competitive pricing as well as always available consistent supply to satisfy global and domestic requirements.

8. Who is the largest exporter of ABS Plastic Sheet?

Singhal Industries Private Limited is the largest exporter of ABS Plastic Sheet, has our products to almost every area of the globe and has an additional focus on innovation, quality and customer satisfaction.

9. Who is the largest manufacturer of ABS Plastic Sheet?

Singhal Industries Private Limited is the largest manufacturer of ABS Plastic Sheet, manufactures a very high-quality product with high technology, to service a variety of world-class industries around the globe.

10. How do ABS sheets compare to 3D WPC wall panels in terms of price?

3D WPC wall panels are great products for decorative applications, however, ABS sheets White rigid plastic is tougher and more industrial, and at a almost similar price point, it can be applied to multiple use cases.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Musik

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness