5 Key Factors to Select High-Quality Aluminium Circle for Spinning

Postado 2025-09-10 05:54:43

0

1K

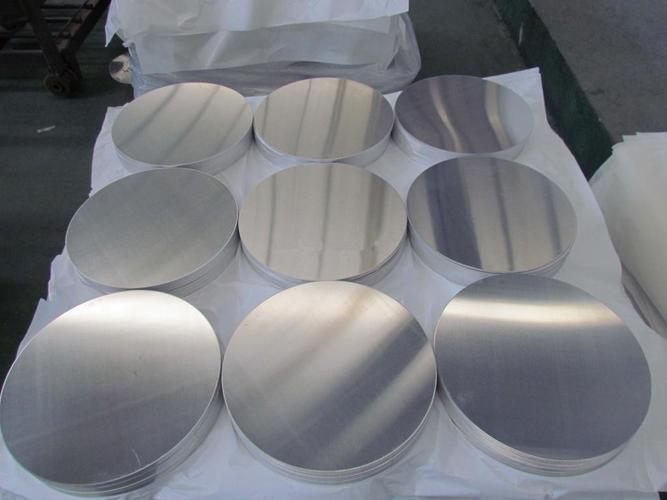

Choosing the right aluminium circle for spinning is critical to ensuring smooth production, reducing defects, and delivering high-performance end products—whether for cookware, lighting, or automotive parts. Below are the five key factors to guide your selection.

1. Choose the Right Aluminium Alloy Grade

The alloy grade determines the circle’s suitability for different spinning needs. Common options include:

- 1050 Alloy: With ≥99.5% aluminium purity, it offers excellent ductility, making it ideal for low-stress products like simple lighting covers or small decor.

- 3003 Alloy: Added manganese (1.0-1.5%) boosts strength and corrosion resistance, suiting medium-stress items such as cookware bodies or ordinary automotive trim.

- 5052 Alloy: Magnesium (2.2-2.8%) enhances tensile strength and formability, perfect for high-stress spinning like pressure cooker liners.

- 6061 Alloy: Heat-treatable with magnesium and silicon, it provides high strength for heavy-duty parts like automotive wheel rims.

Match the alloy to your project: Use ductile grades (1050) for deep spinning and high-strength grades (6061) for load-bearing products. For outdoor or food-contact items, prioritize corrosion-resistant alloys (3003, 5052).

2. Verify Dimensional Accuracy and Flatness

Poor dimensional control leads to uneven spinning and defects. Focus on three parameters:

- Diameter tolerance: Aim for ±0.5mm for general use and ±0.2mm for precision spinning to ensure product uniformity.

- Thickness consistency: Allow no more than 0.1mm deviation—uneven thickness causes uneven stress and cracking.

- Concentricity: Keep inner-outer circle deviation ≤0.3mm for balanced spinning of symmetric parts like pot lids.

Flatness is equally vital: Maximum warpage should be ≤1mm per meter. Poor flatness creates air gaps between the circle and mold, leading to incomplete forming.

3. Evaluate Surface Quality

A high-quality surface ensures both aesthetics and functionality. Inspect for:

- No visible flaws: Scratches (depth ≤0.05mm), pits (diameter ≤0.3mm), stains, or oxidation spots should be absent—critical for visible parts like cookware exteriors.

- Smoothness: Surface roughness (Ra ≤0.8μm) enables easy mold release and prevents material tearing during spinning.

- Coating quality (if applicable): Protective films (e.g., anti-oxidation layers) must be uniform without peeling.

Smooth, defect-free surfaces also reduce mold wear, extending equipment life.

4. Assess Mechanical Properties

Ductility and strength directly impact spinning performance. Key indicators include:

- Elongation at break: Minimum values (1050: ≥25%, 3003: ≥20%, 5052: ≥18%) ensure the circle can stretch without breaking.

- Tensile strength: Balanced strength (1050: ≥75MPa, 6061: ≥276MPa) avoids cracking under spinning pressure.

- Hardness: Ranges like 1050 (HB 15-20) or 5052 (HB 30-35) balance processability and durability.

Verify these via sampling tests or request supplier-provided mechanical property reports.

5. Check Supplier Qualifications

A reliable supplier guarantees consistent quality. Look for:

- Production capacity: Advanced equipment (precision slitting machines, flatness correctors) ensures stable output.

- Certifications: ISO 9001 or industry standards (e.g., ASTM) reflect strict quality control.

- After-sales support: Policies for defective product replacement and technical help for spinning issues are essential.

Request documents like Material Certification (MTC) for alloy verification, quality inspection reports, and batch traceability for troubleshooting.

Summary

Selecting high-quality aluminium circles for spinning requires prioritizing alloy matching, dimensional accuracy, surface quality, mechanical properties, and supplier reliability. This integrated approach reduces waste, extends mold life, and improves end-product competitiveness. For a trusted option that meets these standards, consider Lanren Aluminum’s Aluminium Circle for Spinning.

Pesquisar

Categorias

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leia Mais

Mastering Diablo IV Gold: Tips and Strategies for Maximizing Your D4 Gold Wealth

Mastering Diablo IV Gold: Tips and Strategies for Maximizing Your D4 Gold Wealth

In the vast...

Bulk KN95 Dust Mask

Bulk KN95 Dust Mask With over 10 years of experience in manufacturing medical instruments, we...

Scopri i Prezzi Giocatori FC 25: Analisi e Previsioni per il Mercato del Calcio

Scopri i Prezzi Giocatori FC 25: Analisi e Previsioni per il Mercato del Calcio

Il mercato del...

**Unlock Your Ultimate Gameplay: Buy FC 26 Coins for an Edge in FC 26!**

Why FC 26 Coins Are Essential for Your Gaming Experience

In the vibrant, electrifying universe...

Cómo Comprar FIFA Coins y Monedas EA FC 26 de Manera Segura y Eficaz para Mejorar tu Experiencia en Monedas FC26

Cómo Comprar FIFA Coins y Monedas EA FC 26 de Manera Segura y Eficaz para Mejorar tu...

© 2025 Scenario.press - libera espressione

Portuguese

Portuguese