The Essential Guide to Brown Adson Thumb Forceps

In the world of surgical instruments, precision and reliability are paramount. Surgeons and medical professionals depend on high-quality tools to perform delicate procedures with accuracy. Among the most trusted and versatile of these instruments is the Brown Adson thumb forceps. This tool is a staple in operating rooms and clinics worldwide, valued for its unique design and exceptional grip. Understanding its features, applications, and the importance of quality manufacturing is essential for any medical practice dedicated to patient care and surgical excellence.

Understanding the Design

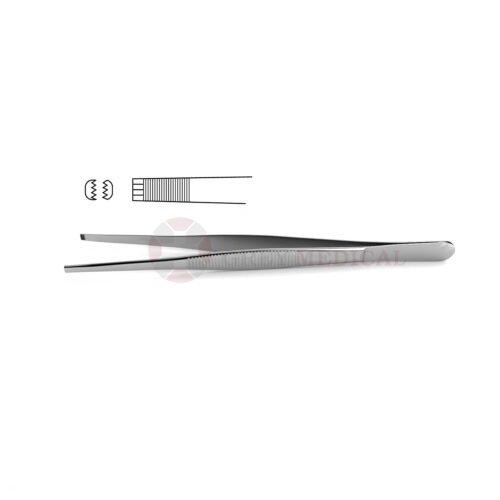

The design of the Brown Adson thumb forceps is what sets it apart. It features a wide, flat thumb grasp area, which provides surgeons with superior control and stability during use. This ergonomic design helps to reduce hand fatigue, a critical factor in long and complex surgical procedures. The working end of the forceps is characterized by multiple rows of fine, interlocking teeth. This configuration ensures a secure yet gentle grasp on delicate tissues, minimizing trauma and damage. The fine-toothed pattern provides a significant advantage over other forceps, which might crush or slip on sensitive structures.

Applications in Surgical Procedures

The versatility of the Brown Adson thumb forceps makes it suitable for a wide range of medical specialties. In plastic and reconstructive surgery, it is indispensable for handling delicate skin flaps and tissues. Dermatologists frequently use it for biopsies and other minor skin procedures. In general surgery, it proves its worth by securely holding tissues, fascia, and muscle during suturing and dissection. The instrument’s ability to provide a firm grip without causing significant harm to the tissue it holds is its most celebrated attribute, making it a go-to tool for precision work.

The Importance of High-Quality Materials

The performance and longevity of any surgical instrument depend heavily on the quality of its construction. For a tool like the Brown Adson thumb forceps, this is especially true. Premium-grade stainless steel is the material of choice, offering corrosion resistance, durability, and the ability to withstand repeated sterilization cycles without degradation. Meticulous craftsmanship ensures that the teeth align perfectly and that the tension of the forceps is calibrated for optimal performance. Inferior instruments can fail at critical moments, potentially compromising patient safety and surgical outcomes.

Proper Care and Sterilization

To maintain the integrity and functionality of these precision instruments, proper care and handling are crucial. After each use, the Brown

Adson thumb forceps should be thoroughly cleaned to remove all biological debris. Following cleaning, a rigorous sterilization process, typically involving an autoclave, is necessary to ensure the instrument is free from microorganisms. Adhering to established protocols for cleaning, inspection, and sterilization not only guarantees patient safety but also extends the life of the instrument, ensuring it remains a reliable tool for countless procedures.

Conclusion

GreyMedical® understands that excellence in surgery begins with excellence in the tools used. Our commitment to innovation and quality is reflected in every instrument we produce. We recognize the critical role that dependable, high-performance tools play in achieving successful patient outcomes. This dedication drives us to craft surgical instruments with unmatched precision and durability, ensuring that medical professionals have the very best in their hands. At GreyMedical®, we are not just manufacturing instruments; we are forging a legacy of excellence and trust in the medical community.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness