ERP for Quality Control: Reducing Defects and Ensuring Product Standards

As someone who has worked closely with manufacturers, I’ve seen how even a small defect can ripple into big losses, both in terms of money and brand reputation..For this reason, I think that any company that produces things needs a quality control department as a lifeline. My experience with ERP systems has shown me how they transform this lifeline by digitizing, automating, and standardizing every check.

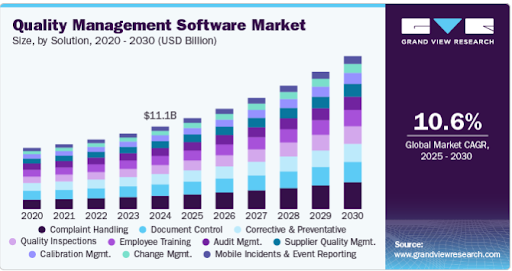

Source: Grand View Research

According to Grand View Research, the global quality management software market is going to reach USD 20.66 billion by 2030 as more businesses rely on technology to satisfy stringent regulations and client requests. This increasing tendency emphasises how integrated quality control modules in ERP solutions are now necessary for maintaining competitiveness and are no longer optional.

The Role of ERP in Quality Control

ERP systems give a single platform for recording and tracking quality checkpoints. This not only lowers human mistakes but also provides real-time visibility throughout the manufacturing process.

From raw material inspections to final product testing, Manufacturing ERP Development, allows firms to establish standard standards that are automatically enforced. I've seen that when teams use ERP for quality, they stop chasing problems and start preventing them.

Real-Time Defect Detection and Alerts

ERP reduces scrap and rework expenses by spotting defects early. This guarantees uniformity while enabling producers to continue producing smoothly.

IoT devices and shop floor sensors are integrated with modern ERP systems, which immediately highlight any deviations from established standards.

Managers receive notifications instantly rather than having to wait for a batch to be finished before identifying errors. This reduces the possibility that customers will get faulty products by enabling them to take remedial action immediately.

Standardizing Processes for Compliance and Certification

Compliance regulations are tightening across industries, and ERP helps ensure that no steps are overlooked. Manufacturers can use standardised workflows to demonstrate conformity to ISO, FDA, and other quality standards.

ERP keeps digital records of all quality checks, making audits faster and more transparent. What particularly impresses me is how it lowers the need for manual reporting, which is prone to errors.

Deeper Dive: How ERP Ensures Quality Across Stages

ERP touches every step of production, ensuring quality isn’t a one-time check but a continuous process. Here’s how it works across stages:

-

Raw Material Check – ERP ensures incoming raw materials meet predefined quality benchmarks.

-

In-Process Inspection – Automated alerts notify supervisors if any operation deviates from standards.

-

Final Product Testing – ERP maintains digital test reports, making customer handovers and audits seamless.

By managing quality across these stages, manufacturers not only reduce defects but also build trust with clients who expect consistency.

Turning Quality into a Competitive Advantage

Superior products increase customer pleasure, lower returns, and fortify enduring company partnerships. ERP transforms quality into a competitive advantage in addition to assisting in defect prevention.

Businesses that use ERP for quality control, in my opinion, not only maintain compliance but also establish a reputation for dependability. Even in congested markets, that reputation is what attracts and retains clients.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness