Aerospace Additive Manufacturing Market Forecast

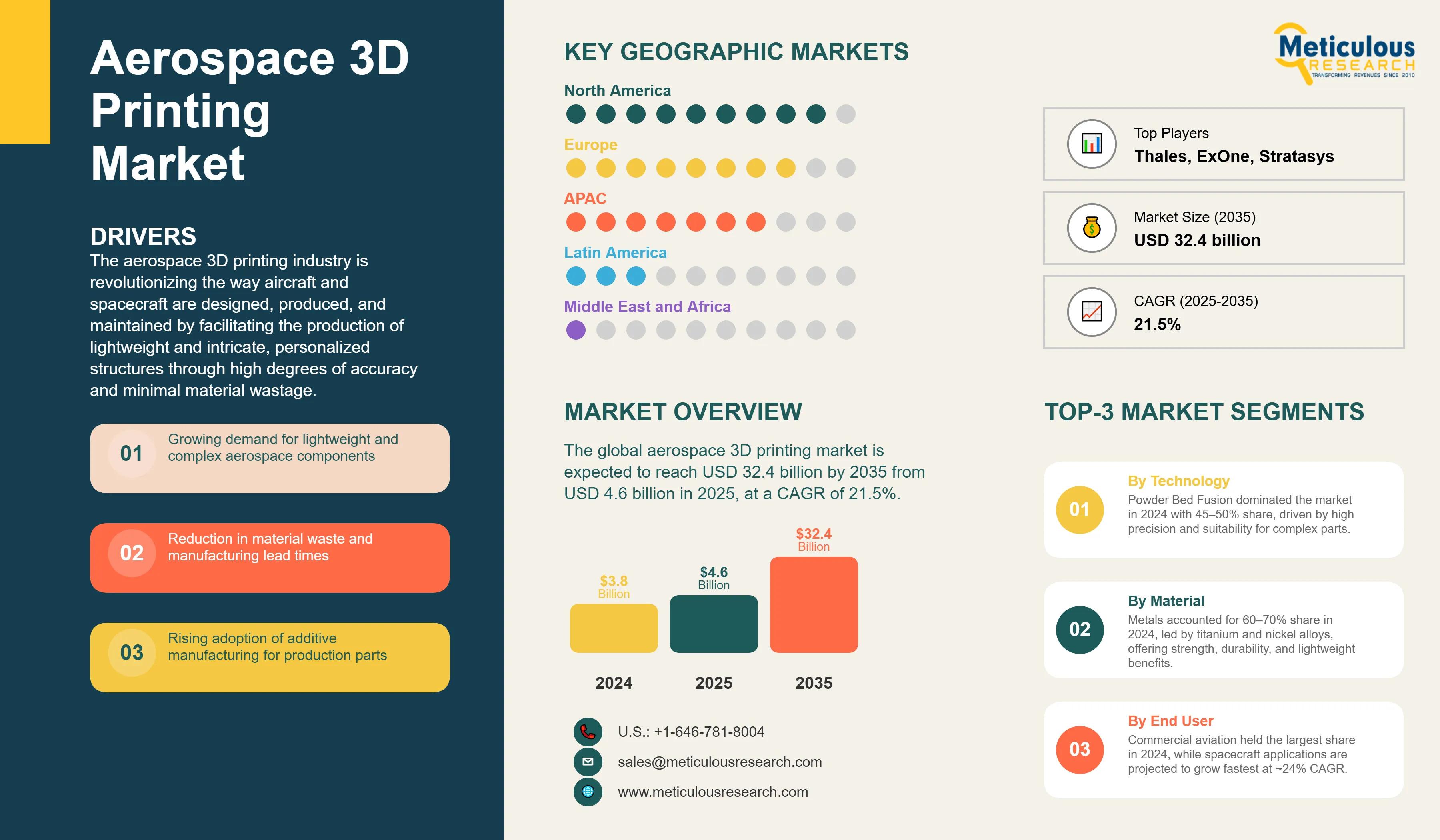

The aerospace industry is experiencing a revolutionary transformation through 3D printing technology, with the global market growing from $3.8 billion in 2024 to an expected $32.4 billion by 2035. This represents an impressive 21.5% annual growth rate, driven by the technology's ability to create lightweight, complex components with minimal waste.

Unlike traditional manufacturing methods that cut away material, 3D printing builds parts layer by layer, allowing engineers to design intricate geometries impossible with conventional techniques. This capability enables the consolidation of multiple components into single, stronger pieces. Major aerospace companies are already seeing real benefits – GE Aviation produces exceptionally durable fuel nozzles for jet engines, while NASA has successfully tested 3D-printed rocket components that withstand extreme conditions.

The competitive landscape features established aerospace giants like Airbus, Boeing, and Lockheed Martin partnering with specialized 3D printing companies such as Stratasys and EOS. Recent breakthroughs highlight the technology's potential: Indian startup Agnikul developed the world's largest single-piece 3D-printed rocket engine from Inconel, earning a U.S. patent. Meanwhile, Spanish company AIMEN created the first 3D-printed cryogenic hydrogen tank for aircraft, supporting sustainable aviation goals.

Several factors are driving this explosive growth. Airlines face mounting pressure to improve fuel efficiency and reduce emissions, and 3D printing delivers by creating lighter components without sacrificing strength. Airbus demonstrated this by integrating titanium 3D-printed brackets into their A350 aircraft, significantly reducing weight while maintaining performance.

Cost efficiency represents another major advantage. GE Aviation's LEAP engine fuel nozzles exemplify this benefit by combining 20 separate parts into one lightweight component, reducing manufacturing complexity while improving durability. Additionally, 3D printing accelerates the development process, allowing companies like NASA to prototype and test components much faster than traditional methods allow.

However, significant challenges remain. The aerospace industry operates under extremely strict safety standards, making certification of 3D-printed parts time-consuming and expensive. While companies like GE Aviation and Boeing have achieved regulatory approval for certain components, the process requires extensive testing to validate structural integrity and long-term performance under extreme conditions.

Geographically, North America leads the market, leveraging its mature aerospace sector and strong government investment. Companies like Boeing, GE Aviation, and NASA drive innovation in advanced materials and complex designs. The region's military applications further accelerate adoption, with the U.S. Air Force successfully recreating over 150 obsolete aircraft parts using 3D printing, reducing replacement times from nine months to just 15 days.

The Asia-Pacific region shows the fastest growth, fueled by rising air travel demand and government initiatives. China's COMAC integrated titanium 3D-printed parts into its C919 jetliner, while India's space program and startups embrace the technology for rocket engines. The UAE is positioning itself as a manufacturing hub, with Emirates Engineering producing certified aircraft cabin components.

Technically, Powder Bed Fusion technology dominates with 45-50% market share, particularly for critical components requiring high precision. Metal materials account for 60-70% of revenue, with titanium and nickel-based superalloys leading due to their strength-to-weight ratios and high-temperature performance.

The aircraft platform segment commands the largest share at 50-60%, with commercial aviation rapidly adopting the technology. Boeing's 787 Dreamliner currently uses 20-30 certified 3D-printed parts, while the newer 777X will feature over 310 additive manufactured components per aircraft.

Looking ahead, spacecraft applications show the highest growth rate at 24% annually, with companies like SpaceX using 3D printing for engine components and Relativity Space developing entirely 3D-printed launch vehicles. This technology is reshaping aerospace manufacturing from prototyping to full production, offering unprecedented design freedom, cost savings, and performance improvements across the industry.

Download Sample Report Here https://www.meticulousresearch.com/download-sample-report/cp_id=6244

Contact Us:

Meticulous Research®

Email- sales@meticulousresearch.com

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness