Choosing the Right Construction Hoist Mast Section for Your Project

Choosing the Right Construction Hoist Mast Section for Your Project

Introduction

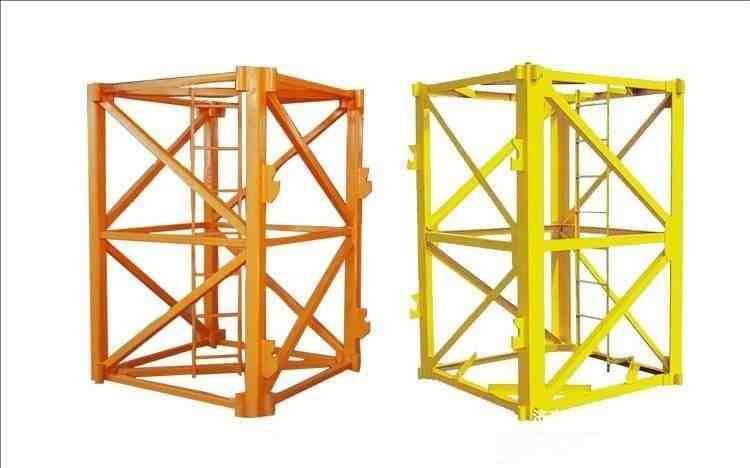

Not all mast sections are the same. The choice of mast section directly impacts the safety, efficiency, and cost-effectiveness of a construction hoist. Contractors must carefully evaluate mast section specifications to match their project needs.

Factors to Consider When Selecting Mast Sections

Size and Compatibility – Mast sections come in various dimensions (e.g., 650×650 mm, 800×800 mm). Compatibility with your hoist brand and model is essential.

Steel Quality – High-grade Q345B or equivalent steel offers better durability and load capacity.

Surface Treatment – Hot-dip galvanization or painting helps resist corrosion on outdoor sites.

Rack Quality – Precision-machined racks ensure smooth climbing without gear damage.

Connection System – Bolted and reinforced connections improve assembly safety and reduce vibration.

Safety and Maintenance Tips

l Inspect mast sections regularly for cracks, rust, or deformation.

l Ensure proper torque tightening on bolts.

l Replace worn-out racks promptly to avoid gear slipping.

Benefits of High-Quality Mast Sections

Improved Stability – Reduces cage vibration and improves ride comfort.

Longer Service Life – With proper treatment, mast sections can withstand years of use.

Lower Operational Risks – A solid mast guarantees safety for both workers and materials.

Conclusion

Choosing the right mast section is more than a purchasing decision—it’s a safety guarantee. By investing in reliable construction hoist mast sections, project managers can ensure smoother operations and fewer risks throughout the construction process.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness