Is a Digital Pressure Gauge Waterproof or Weatherproof?

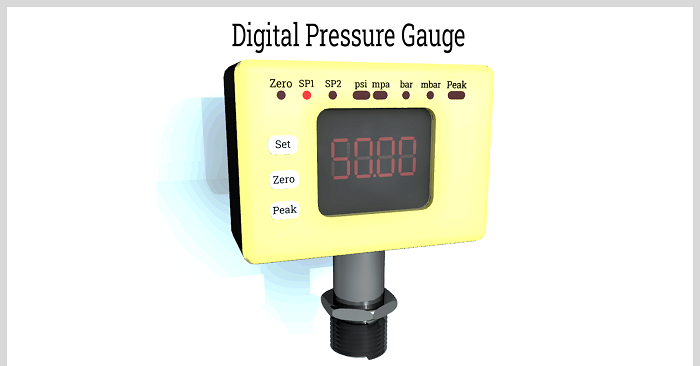

A digital pressure gauge is a device used to measure and display pressure readings electronically. It replaces the traditional analog dial with a digital display that shows accurate measurements. Digital pressure gauges are used in industries such as manufacturing, oil and gas, water treatment, and laboratory testing. Many users wonder whether a digital pressure gauge is waterproof or weatherproof. This question matters because these devices often operate in environments where moisture, dust, or changing weather conditions are present.

Understanding the difference between waterproof and weatherproof is important before exploring how a digital pressure gauge is built. Waterproof means the device can resist water entry even during direct contact or immersion. Weatherproof means the device can withstand environmental factors like rain, humidity, or dust but may not be suitable for full water submersion. This article explains these terms, looks at construction features, and explores how to choose the right digital pressure gauge for outdoor or wet conditions.

Waterproof and Weatherproof Definitions

Waterproof meaning

When a device is waterproof, it can prevent water from entering its internal components even if submerged. Manufacturers often test waterproofing using specific standards, such as IP ratings, to confirm performance. A waterproof digital pressure gauge can be used in applications where water exposure is constant or where immersion may occur.

Weatherproof meaning

Weatherproof refers to a device’s ability to withstand outdoor conditions. A weatherproof digital pressure gauge can resist rain, wind-driven moisture, and dust. However, it is not designed for prolonged water immersion. Weatherproofing focuses on protecting the device during normal environmental exposure rather than extreme water contact.

Digital Pressure Gauge Construction and Sealing

Housing materials

The outer case of a digital pressure gauge plays a key role in protection. Common materials include stainless steel, aluminum, or high-grade polymers. Stainless steel housings offer corrosion resistance and strength for outdoor conditions. Polymer housings can provide lighter weight and insulation against electrical interference.

The durability of the housing helps protect against water and weather damage. However, the level of protection also depends on sealing methods used during assembly.

Sealing technology

A digital pressure gauge may have seals made from rubber, silicone, or other flexible materials. These seals are placed around display screens, buttons, and connection points. Proper sealing prevents water and dust from entering the device. The thickness and placement of seals influence whether the device is considered waterproof or weatherproof.

High-quality digital pressure gauges often include O-rings or gasket seals at every joint to increase resistance against moisture.

IP Ratings and Protection Levels

Understanding IP codes

The Ingress Protection (IP) rating is a standard system that indicates how well a device resists solids and liquids. The first number shows protection against solids like dust. The second number shows protection against liquids like water.

For example, an IP67 rating means the digital pressure gauge is dust-tight and can be submerged in water up to a certain depth for a limited time. An IP65 rating means the device is dust-tight and can resist low-pressure water jets but is not suitable for immersion.

Choosing the right IP rating

For outdoor weather use, an IP65 or higher rating is often recommended. For environments with potential water submersion, IP67 or higher is more suitable. Checking the IP rating before purchase ensures that the digital pressure gauge meets the required protection level for the intended application.

Applications Requiring Waterproof or Weatherproof Gauges

Industrial outdoor installations

In industrial settings, a digital pressure gauge may be mounted on pipelines, tanks, or pumps located outside. In these situations, rain, wind, and dust are common. A weatherproof gauge with a suitable IP rating ensures reliable operation without damage from environmental exposure.

Marine and underwater operations

Marine applications require gauges that can handle saltwater exposure and possible submersion. A waterproof digital pressure gauge with corrosion-resistant materials is necessary for ships, docks, or underwater equipment. Saltwater can be especially damaging, so both waterproofing and material choice are important.

Food and beverage production

In food processing plants, cleaning processes often involve spraying equipment with water. A waterproof digital pressure gauge ensures that cleaning procedures do not damage the device. These gauges also need to be made from materials that meet hygiene standards.

Limitations and Considerations

Temperature effects

Extreme temperatures can affect the performance of a digital pressure gauge. Even if the gauge is waterproof, freezing conditions can cause water inside to expand and damage seals. High temperatures can also cause seal materials to degrade over time.

Battery and electronics protection

The electronics inside a digital pressure gauge are sensitive to moisture. If water bypasses the seals, it can cause short circuits or display errors. Therefore, battery compartments are usually sealed separately from the main sensor.

Weatherproof models may have breathable membranes to allow air exchange without letting water in. This helps prevent condensation inside the device.

Maintenance for Longevity

Regular inspection

Inspecting the seals, housing, and connectors of a digital pressure gauge helps maintain protection. If cracks or wear are noticed in seals, they should be replaced promptly.

Cleaning practices

When cleaning a waterproof or weatherproof digital pressure gauge, gentle wiping with a damp cloth is often recommended. Harsh cleaning methods, such as high-pressure jets, should only be used if the device is rated for that type of exposure.

Storage conditions

When not in use, storing the device in a dry, temperature-controlled environment extends its lifespan. Even waterproof gauges benefit from avoiding unnecessary exposure to harsh weather when not required.

Conclusion

Whether a digital pressure gauge is waterproof or weatherproof depends on its design, materials, and sealing methods. Waterproof gauges can handle immersion, while weatherproof gauges are built to withstand outdoor conditions without full submersion. The IP rating provides a clear measure of protection level.

In applications such as industrial outdoor use, marine environments, or food production, selecting the correct type of digital pressure gauge ensures reliability and safety. Regular maintenance and proper storage further protect the device and extend its life.

Understanding the difference between waterproof and weatherproof helps users choose the right equipment for their needs. By checking construction details and IP ratings, it is possible to match the digital pressure gauge to the specific challenges of its operating environment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness