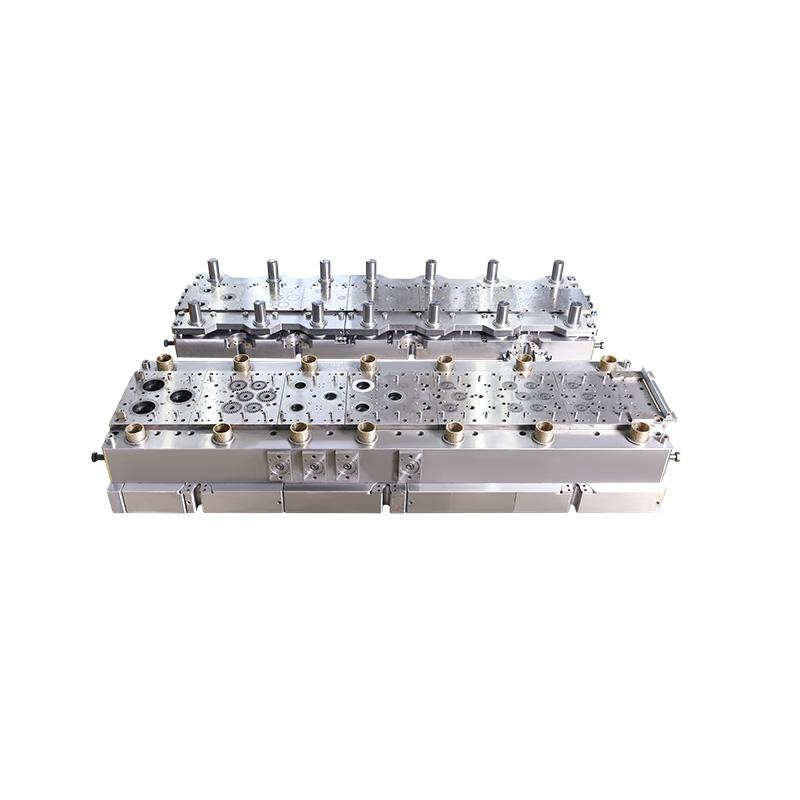

How Precision Stamping Molds Deliver Flawless Surfaces

In the realm of high-volume manufacturing, achieving impeccable surface quality directly out of the press is a holy grail. This is where the Precision Stpping Mold truly excels, offering a level of Excellent Surface Finish that drastically reduces or even eliminates the need for costly secondary processing. The inherent smoothness and burr control achieved are fundamental advantages of utilizing a true Precision Stamping Mold.

The secret starts within the mold itself. The forming surfaces of a high-end Precision Stamping Mold – the cavities, cores, punches, and dies – undergo meticulous finishing processes. Techniques like diamond polishing and mirror grinding create surfaces of extraordinary smoothness, often achieving a near-optical finish (Ra values in the hundredths of a micron). This flawless mold surface acts like a master template. During the high-pressure stamping operation, it imparts its own exceptional smoothness directly onto the metal part being formed. Consequently, parts ejected from a Precision Stamping Mold inherently possess a superior, consistent surface state, ready for plating, painting, or immediate assembly without time-consuming grinding or polishing.

Equally critical to surface quality is the mold's ability for Stringent Burr Control. Precision isn't just about dimensions; it's about edge perfection. A top-tier Precision Stamping Mold is engineered to minimize burr formation at the microscopic level. Through exacting control of cutting clearances (often within microns), specialized edge preparation techniques (like controlled-edge radii or shear angles), and the use of ultra-sharp, wear-resistant tool steels (often coated with PVD/CVD for longevity), these molds produce parts with burr heights minimized to mere microns (µm) and maintained with remarkable uniformity across millions of cycles.

This combination of ultra-smooth surfaces and near-invisible, consistent burrs is non-negotiable for demanding applications. In automotive fuel injectors, smooth flow paths prevent turbulence. In medical implants, flawless surfaces minimize bacterial adhesion sites. In intricate electronic connectors, microscopic burrs can cause shorts or prevent proper mating. The Precision Stamping Mold delivers the pristine surfaces and clean edges essential for reliable function, airtight seals, smooth mechanical operation, and perfect fit in high-precision assemblies. It transforms raw material into near-finished components, embodying excellence from the inside out.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness