Evaluating the Impact of Humidity and Cold Temperatures on Industrial Saw Cutting Performance

Environmental conditions play a crucial role in the operation and longevity of industrial machinery. When using an aluminum plate cutting circular saw machine, factors like high humidity and low ambient temperatures can influence performance in subtle but significant ways. It is essential to assess how such machines behave under challenging conditions, particularly in regions where seasonal changes or specific industrial environments introduce moisture or cold into the workspace.

High humidity levels introduce the risk of condensation forming on machine components, especially metal surfaces. Over time, this can lead to corrosion, particularly on exposed parts such as the blade spindle, guiding rails, or motor housing. While aluminum itself resists rust, many machine components are made from steel or incorporate electrical circuits vulnerable to moisture damage. If not protected, electronic controls, sensors, and motors may experience degraded insulation, short-circuiting, or reduced responsiveness. Regular maintenance and the use of protective coatings or sealed enclosures are critical for safeguarding the electrical integrity of the system.

Moreover, humidity can negatively affect the materials being processed. Aluminum plates stored in humid conditions may accumulate surface moisture, which, if not dried before cutting, could interfere with cutting precision or lead to chip adhesion on the blade. Wet chips can clog extraction systems more easily, increasing maintenance requirements.

In contrast, extremely low temperatures may alter the mechanical behavior of machine components. Lubricants used for bearings, guides, and feed systems may become more viscous in cold environments, reducing their effectiveness and potentially causing additional resistance during operation. This can result in slower movement, uneven feeding, or excessive wear on moving parts. Cold metal components are also more prone to brittleness, which may increase the risk of cracking or failure under high loads or vibration.

For cutting operations specifically, blade performance can be impacted by temperature changes. In colder settings, saw blades may contract slightly, altering tension and possibly reducing cutting accuracy. If thermal expansion and contraction cycles occur frequently, misalignment can become an issue over time.

Despite these risks, many industrial machines are engineered with some level of environmental tolerance. Manufacturers often specify operating ranges for temperature and humidity, and machines designed for harsh settings may feature weather-sealed control panels, corrosion-resistant coatings, or low-temperature-compatible lubricants. Users should refer to these specifications before installing such equipment in non-climate-controlled environments.

To ensure optimal performance in humid or cold environments, several preventative measures can be taken. These include installing dehumidifiers or insulation within the workspace, using heaters for critical parts like control panels or motors, and performing more frequent lubrication using temperature-appropriate grease or oil. It’s also wise to pre-warm the machine before starting cutting operations to ensure thermal stability.

In summary, while an aluminum plate cutting circular saw machine is built for precision and reliability, its performance can be influenced by environmental extremes. High humidity can cause corrosion and electrical faults, while cold temperatures may impact lubrication, material behavior, and blade dynamics. With proper precautions and maintenance, however, these machines can operate effectively even in less-than-ideal conditions. Always consult manufacturer guidelines and apply appropriate environmental controls to maintain safety, accuracy, and productivity.

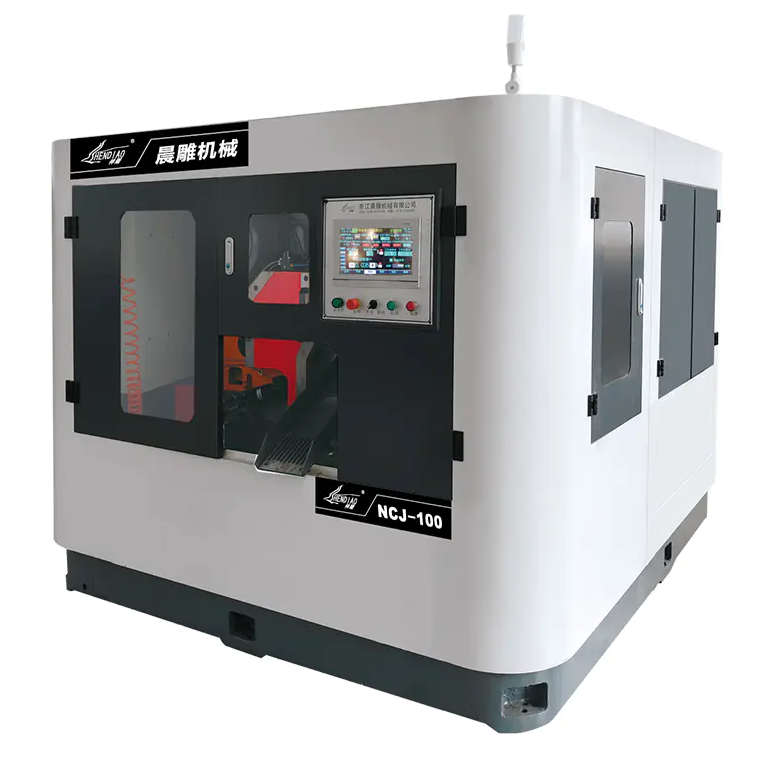

Cutting Range(mm): 160×3100

Saw Blade Size(mm): Φ550×38×3.5/Diameter×Thickness×Inner Orifice

Feeding Speeds: Stepless Speed Control

Saw Blade Speed(m/min): 2860

Total Power(kw): 21.7

Fastening Mode: Air Pressure

Overall Size(mm): 7000×6150×2150

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness