Speed & Savings: How Automotive Plastic Molding Masters Efficiency

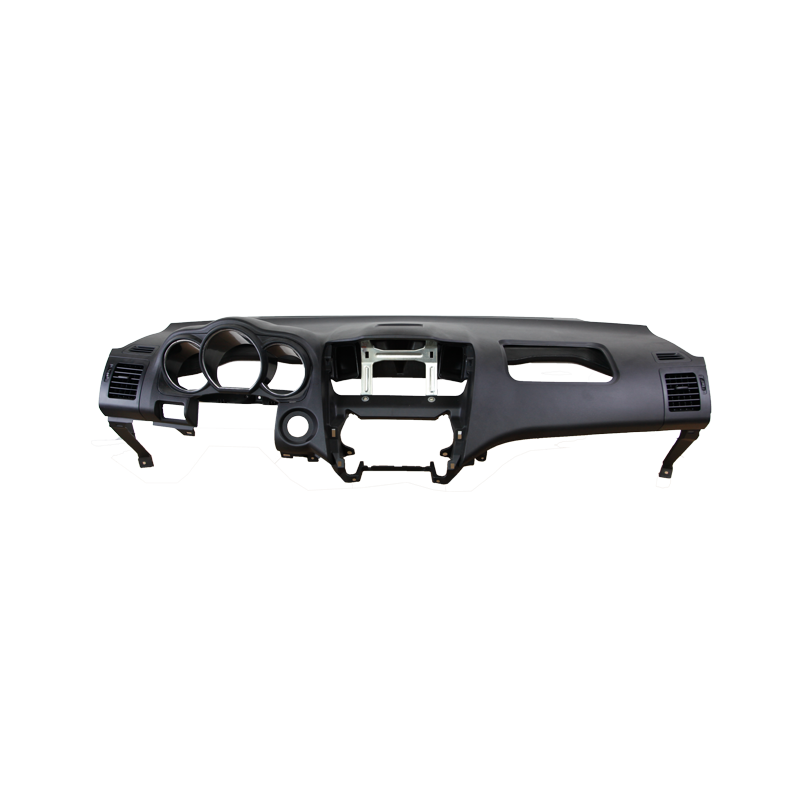

In the fiercely competitive automotive industry, automotive plastic molding stands out not just for its design versatility, but as a powerhouse of production efficiency and cost control. This advanced manufacturing process is fundamentally engineered for high-volume output, making it the go-to solution for modern vehicle production lines seeking speed and economy.

The inherent nature of automotive plastic molding, particularly injection molding, delivers exceptionally short cycle times. Components can be formed, cooled, and ejected in mere seconds or minutes, dramatically outpacing traditional metal fabrication methods like machining, casting, or stamping. This rapid turnaround is perfectly suited for the massive scale demands of the auto sector. Furthermore, automotive plastic molding integrates seamlessly with high-level automation. Robotic arms handle part removal, intricate insert loading, post-molding operations, and assembly, enabling lights-out production with minimal human intervention and maximizing throughput.

Crucially, automotive plastic molding offers significant cost advantages, especially at high volumes. While the initial mold tooling requires investment, this cost is often substantially lower than the complex, multi-stage dies needed for high-volume metal parts. More importantly, the unit cost per plastic component becomes highly favorable in mass production. Once the mold is running, the combination of fast cycle times, automation, and relatively low raw material costs (compared to metals) drives down the price per piece significantly. This cost efficiency is a cornerstone of automotive plastic molding's value proposition.

Material utilization is another area where automotive plastic molding excels. The process generates minimal waste compared to subtractive metal machining; excess material (sprues and runners) is often reground and reused. The ability to design complex, integrated parts through automotive plastic molding – consolidating what were multiple metal components into a single molded piece – further slashes assembly time, labor costs, and inventory complexity, compounding the savings.

From intricate electrical connectors and fluid housings to durable interior panels and under-the-hood components, automotive plastic molding delivers the speed, scalability, and cost-effectiveness automakers demand. Its dominance in producing millions of consistent, high-quality parts efficiently and economically ensures automotive plastic molding remains an indispensable pillar of cost-conscious, high-volume vehicle manufacturing worldwide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Musik

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness