Revolutionize Surface Prep with Laser Cleaning Metal Solutions by Mart Laser

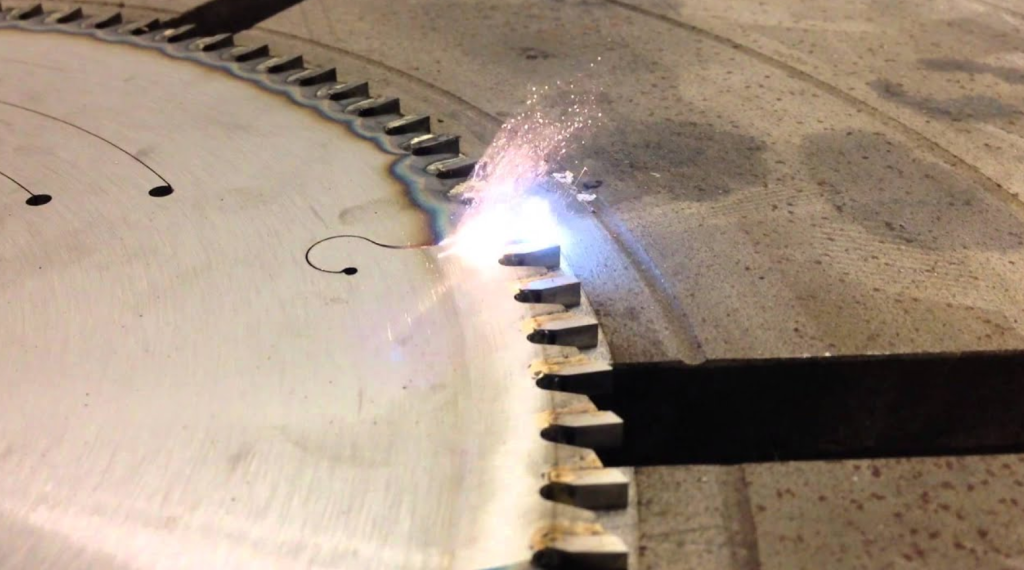

In today’s industrial landscape, efficiency, precision, and environmental responsibility are more important than ever. One area where these values truly converge is in laser cleaning metal—a transformative technology for removing rust, paint, and other surface contaminants without the use of chemicals or abrasive materials. At the forefront of this innovation is Mart Laser, a reliable name delivering advanced laser cleaning systems tailored to modern manufacturing and maintenance needs.

What is Laser Cleaning for Metal?

Laser cleaning metal is a non-contact process that utilizes high-energy laser beams to vaporize contaminants from metal surfaces. Unlike traditional methods like sandblasting or chemical dipping, laser cleaning offers high accuracy, minimal substrate damage, and zero consumable costs. The technology is especially beneficial in sectors like automotive, aerospace, shipbuilding, and heavy machinery where surface integrity is paramount.

Why Choose Mart Laser for Your Metal Cleaning Needs?

Mart Laser stands out by offering powerful, portable, and user-friendly laser cleaning machines that integrate the latest in fiber laser technology. Whether you're preparing surfaces for welding, removing rust from old tools, or cleaning precision parts, Mart Laser machines offer adjustable power and speed settings that suit a wide range of metal types and industrial applications.

Key highlights of Mart Laser’s solutions:

-

High-efficiency cleaning with minimal heat input

-

Precise, damage-free surface treatment

-

Long machine life with low maintenance

-

Safe and eco-friendly, with no secondary pollution

Each unit is engineered with industrial users in mind, offering plug-and-play operation, ergonomic design, and comprehensive safety features.

Real-World Benefits for Manufacturers and Repair Shops

Using Mart Laser’s laser cleaning metal equipment can significantly reduce downtime, lower labor costs, and improve the overall quality of surface preparation. Compared to traditional cleaning methods, laser technology requires less cleanup, no masking, and produces no hazardous waste. This makes it ideal for industries that must meet strict environmental or safety regulations.

In addition, Mart Laser provides training, after-sales support, and technical assistance to ensure customers get the most value from their investment. Their machines are designed for both small workshops and large-scale industrial operations.

Customization and Scalability

Mart Laser understands that no two businesses are the same. That's why they offer customizable power levels (ranging from 100W to 2000W and beyond), optional cooling systems, and multiple lens options to match specific metal types and cleaning requirements. Whether you're dealing with stainless steel, carbon steel, or aluminum, there’s a solution tailored for your exact application.

Final Thought

If your business is looking for a cleaner, faster, and safer way to handle metal surface preparation, Mart Laser’s laser cleaning metal machines provide a smart, future-proof investment. Backed by technical excellence and a commitment to innovation, Mart Laser is helping manufacturers unlock new levels of productivity and sustainability in surface treatment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness