How Box Moulds Revolutionize Modern Production Processes

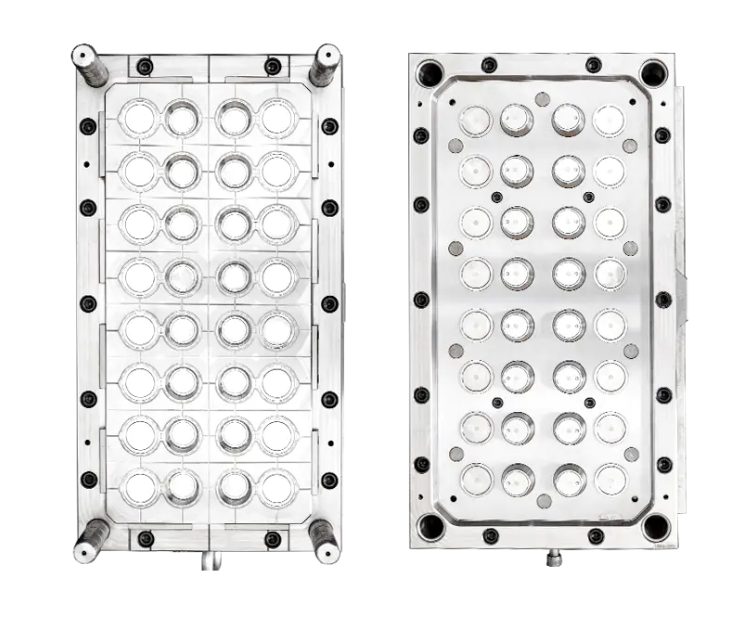

Box moulds are integral to the production of a wide variety of products across multiple industries. These moulds are used to shape materials such as plastic, metal, and concrete into standardized forms, which are essential for creating boxes and containers used in packaging, transportation, and storage. The importance of box moulds in modern production processes cannot be overstated, as they streamline manufacturing, improve product consistency, and reduce costs.

At the core of any box mould is its ability to produce items with precise dimensions and shapes. Manufacturers rely on box moulds to create products that meet specific requirements for size, shape, and material composition. Whether it is for consumer goods, industrial packaging, or even construction materials, box moulds are critical in ensuring that each product fits within the intended design parameters. This accuracy ensures that products are functional, aesthetically pleasing, and fit for purpose.

In the packaging industry, for example, box moulds are used to create boxes that hold everything from food and beverages to electronics and machinery parts. The consistent size and shape of these boxes are crucial for ensuring that products are stored and transported safely. Improperly shaped boxes could lead to issues such as product damage or inefficient use of storage space. With the use of box moulds, manufacturers can produce standardized packaging solutions that cater to a wide variety of products, improving logistical efficiency and reducing potential losses.

Box moulds are also beneficial for mass production. Once a box mould is designed and manufactured, it can be used to create thousands, if not millions, of identical products. This high level of repeatability ensures that manufacturers can produce large volumes of items quickly and efficiently without sacrificing quality. As the demand for products increases, the ability to scale production becomes a key advantage. Box moulds enable manufacturers to keep up with demand by facilitating large-scale production runs with minimal downtime and reduced labor costs.

The use of box moulds also contributes to reducing waste in the manufacturing process. The precision of the mould ensures that the right amount of material is used, minimizing excess material that could be discarded. Additionally, many modern box moulds are designed with features that improve material flow and reduce defects. These advanced features help manufacturers maintain a high level of consistency while reducing the need for rework or scrap materials.

A key aspect of box moulds is their ability to adapt to different materials. Box moulds are commonly used for plastic injection molding, but they can also be used for materials like metal, rubber, or even concrete. This versatility allows manufacturers to create a broad range of products using the same basic principles of moulding. Depending on the application, box moulds can be customized to suit the specific material being used, ensuring that the final product meets the necessary performance and quality standards.

Another important benefit of box moulds is their ability to reduce the time and labor required to create products. Traditional manufacturing methods may involve more manual labor and longer production cycles. With box moulds, many of the processes are automated, reducing human intervention and speeding up production times. This increased efficiency helps manufacturers lower production costs and increase profitability.

In conclusion, box moulds play a vital role in modern manufacturing, offering benefits such as precision, scalability, and cost-effectiveness. Their ability to produce large quantities of identical products quickly and efficiently has revolutionized industries such as packaging, automotive, and construction. By improving the consistency of the products and reducing waste, box moulds help manufacturers meet the increasing demand for high-quality items at competitive prices. As industries continue to evolve, the role of box moulds in the production process will remain indispensable for achieving operational excellence and maintaining product quality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness