What Are the Advantages of CNC Aluminum Machining?

CNC aluminum machining offers a wide range of advantages that make it a popular choice for various applications. Here's a breakdown of some of the key benefits:

l Versatility: CNC machining can handle a wide range of aluminum alloys, from soft and easy-to-machine varieties to high-strength options. This versatility allows for the creation of parts with diverse properties to suit different functional needs.

l Design Flexibility: CNC machining can create complex geometries, intricate features, and even 3D shapes with high precision. This design freedom allows engineers to bring their ideas to life and optimize parts for performance or weight reduction.

l Precision and Accuracy: CNC machining utilizes computer-controlled tools, allowing for incredibly precise and repeatable results. This translates to parts with tight tolerances and consistent dimensions, crucial for applications requiring high accuracy, such as aerospace components or medical devices.

l Lightweight Parts: Aluminum is a naturally lightweight metal, and CNC machining allows for the creation of hollow or weight-reduced features. This is ideal for applications where weight is a critical factor, such as in aerospace or automotive components.

l Fast Production: CNC machining is a relatively fast production process, especially for high-volume runs. The automation and precision of the process minimize setup times and ensure consistent production speeds.

l Cost-Effective for Complex Parts: While there might be an initial setup cost, CNC machining can be cost-effective for producing complex parts. The precision and reduced material waste compared to traditional methods can outweigh the upfront investment.

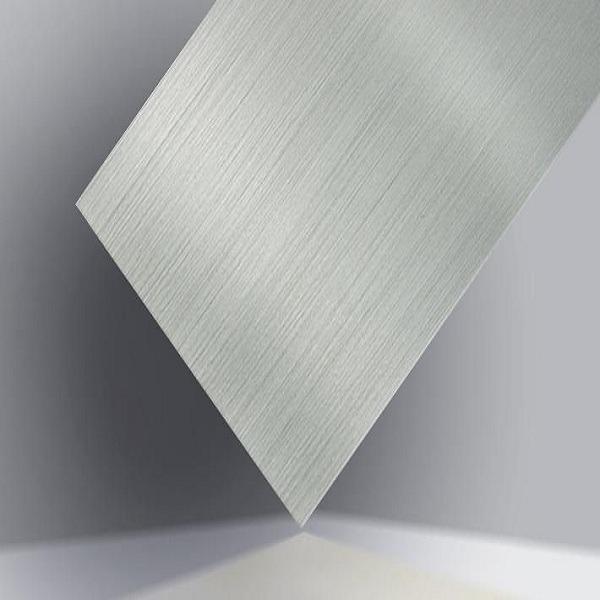

l Good Surface Finish: CNC machining can achieve good surface finishes on aluminum parts, depending on the machining parameters and tooling used. This can sometimes eliminate the need for additional finishing steps, saving time and cost.

l Environmentally Friendly: CNC machining can be a relatively clean process compared to some traditional metalworking techniques. Modern CNC machines often incorporate features like coolant recycling and chip management to minimize waste.

l Repeatability: CNC programs ensure consistent and repeatable part production. This is crucial for maintaining quality control and achieving identical parts in large batches.

There is more information about CNC such as How to Avoid Undesirable Deformation in CNC Aluminum Machining?

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness