Precision Metal Stamping vs Ordinary Metal Stamping: Which Process to Choose

Metal stamping is a common manufacturing process, with stamped metal parts finding widespread applications across various industries. However, within the realm of metal stamping, there exists a notable distinction between ordinary metal stamping and precision metal stamping. In this article, we'll delve into the nuances of precision metal stamping, its characteristics, advantages, applications, and considerations for choosing the right stamping process.

What is Ordinary Metal Stamping?

Ordinary metal stamping primarily involves relatively thick substrates without the need for intricate cutting, stretching, or other complex processes. Furthermore, the precision requirements for parts produced through ordinary metal stamping are not particularly high.

What is Precision Metal Stamping?

Precision metal stamping, on the other hand, demands meticulous attention to detail, incorporating a synergy of precise punching machines, materials, molds, lubricating oils, and advanced technologies. This method places a premium on achieving high levels of precision in the stamped parts, making it an ideal choice for applications where precision is paramount.

Applications of Precision Metal Stamping:

Automotive and Aerospace: Precision metal stamping plays a pivotal role in manufacturing parts for the automotive and aerospace industries. These parts must meet stringent standards, making precision stamping a necessity.

Electronics Industry: The electronics sector relies on precision metal stamping to produce intricate components such as sockets, circuit breakers, and fuse boxes.

Medical: Precision metal stamping proves invaluable in creating medical components, including temperature probes and surgical equipment.

Renewable Energy: This process finds application in renewable energy sectors, contributing to the production of components for solar panels and related equipment.

Specialized Parts: Precision metal stamping is ideal for crafting complex or highly specialized items across various industries.

Choosing Between Ordinary and Precision Metal Stamping:

The choice between ordinary and precision metal stamping hinges on the precision requirements and production volume:

For high-precision parts in large quantities: Opt for precision metal stamping.

For low-precision parts: Ordinary metal stamping is a suitable choice.

Characteristics of Precision Metal Stamping:

Strict Tolerance Requirements: Precision metal stamping demands strict tolerance adherence, showcasing an exceptionally high level of precision.

Flexibility and Adaptability: This method exhibits robust flexibility and adaptability, making it ideal for mass production.

Complex and Tiny Part Production: Precision metal stamping excels in creating intricate, small parts, particularly suited for the aerospace industry.

Computer-Aided Simulation: Before embarking on precision metal stamping operations, computer modeling simulations are often employed to identify errors or defects. This significantly reduces the likelihood of errors during the actual process.

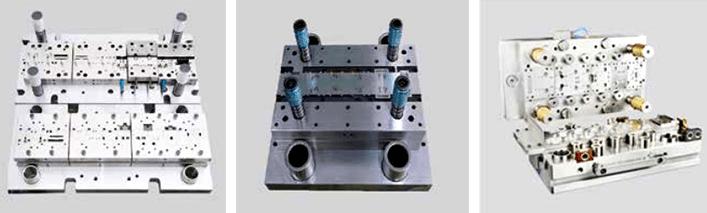

High-Quality Mold: Precision metal stamping relies on molds with outstanding wear resistance, ductility, fatigue resistance, and high-temperature resistance.

High-Precision Equipment and Materials: Utilizing high-precision machines and materials is crucial to achieving the desired results in precision metal stamping.

Requirements for Precision Metal Stamping Dies:

High Strength and Wear Resistance: Precision metal stamping dies must possess high strength and exceptional wear resistance to withstand the rigors of the metal stamping process.

Ductility: Ductility is critical to prevent brittle fracture during mold operation.

High Temperature Resistance: The dies should exhibit good high-temperature resistance to maintain strength and hardness when exposed to elevated temperatures.

Anti-Fatigue Properties: To withstand long-term cyclic pressure, precision metal stamping dies must have excellent fatigue resistance.

If you require precision metal stamping parts, KENENG is a reliable source for your needs. Their expertise spans various components, from stamping dies to precision connectors, metal clips, brackets, screws, springs, and more. With their extensive experience in the hardware industry, KENENG offers mature stamping production processes and a dedicated team. Simply reach out with your requirements, and they'll provide you with a tailored, cost-effective solution. Welcome customers from all corners to inquire and collaborate with them at your convenience.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness