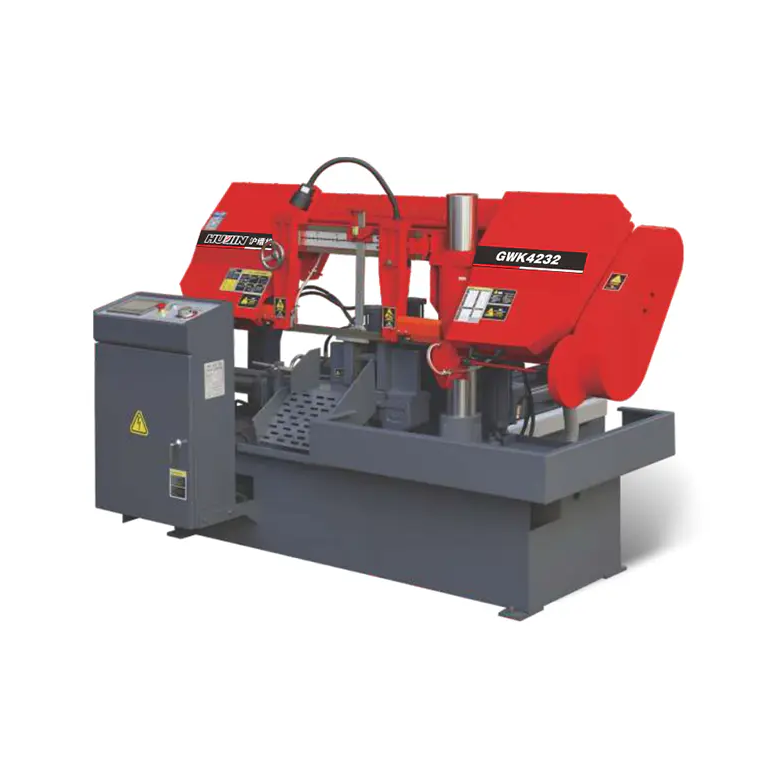

How to Optimize Horizontal Band Saw Machine for Maximum Cutting Efficiency

Improving the cutting efficiency of a Horizontal Band Saw Machine is crucial for manufacturers and workshops aiming to maximize productivity, reduce operational costs, and maintain high-quality output. The cutting efficiency is influenced by multiple factors, including machine maintenance, blade selection, operational parameters, and automation features. By optimizing these aspects, users can achieve faster cutting speeds, longer blade life, and smoother workflows.

One of the most significant ways to enhance efficiency is by selecting the appropriate blade for the material and type of cut. The blade’s tooth pitch, width, and material must match the hardness and thickness of the workpiece. For example, coarse-toothed blades work well for soft materials and faster cuts, while finer teeth are better suited for hard materials requiring smooth finishes. Using an unsuitable blade often results in slower cutting speeds, premature blade wear, and poor surface quality, all of which reduce overall efficiency.

Proper blade tension and alignment are also critical to maintaining high cutting efficiency. A blade that is too loose can wander during cutting, causing inaccurate cuts and increased wear. Conversely, over-tightening the blade increases stress on the machine components and may lead to breakage. Regular inspection and adjustment of blade tension ensure the saw operates smoothly, reducing downtime and improving cut quality.

Another factor that impacts cutting efficiency is the feed rate and cutting speed settings. Optimizing these parameters for the specific material and blade combination can significantly reduce cycle times without compromising the cut quality. Many modern Horizontal Band Saw Machines offer variable speed drives and programmable feed controls, allowing operators to fine-tune the cutting process. Running the saw at an ideal speed reduces excessive heat buildup and wear, prolonging blade life and maintaining efficiency over time.

Maintenance of the machine also plays a vital role in sustaining cutting performance. Regular lubrication of moving parts, cleaning debris from blade guides, and checking for wear on bearings and drive systems minimize mechanical resistance and vibrations that can slow down the cutting process. Well-maintained machines operate more reliably and maintain their precision, directly contributing to improved efficiency.

Automation features such as automatic feeding and material clamping further enhance the efficiency of a Horizontal Band Saw Machine. By automating repetitive tasks, the machine reduces manual intervention, speeds up loading and unloading, and ensures consistent material positioning. This not only saves time but also reduces errors and variability between cuts, which improves overall throughput.

Additionally, the use of coolant systems during cutting can aid in efficiency by reducing heat generated during the cutting process. Coolant improves blade life and cutting speed by lubricating the blade and workpiece interface and flushing away metal chips. This helps maintain a consistent cutting performance, especially when working with harder materials or continuous production runs.

Training operators to understand the machine’s capabilities and optimal settings is also important. Skilled operators can adjust parameters effectively based on the material and job requirements, identify potential issues early, and ensure the machine runs at peak efficiency. Investing in operator training complements technical improvements and maximizes the return on investment in the Horizontal Band Saw Machine.

In conclusion, enhancing the cutting efficiency of a Horizontal Band Saw Machine involves a combination of correct blade selection, proper machine maintenance, optimization of operational parameters, utilization of automation, and effective use of coolant. Attention to these areas leads to faster cutting times, reduced wear and downtime, and higher quality cuts, thereby significantly improving overall productivity in various manufacturing environments.

Cutting Capacity(mm):Round material Φ500/Plate 500x500

Blade speed(m/min):30,60,80

Blade Size(mm):1.3*41*6200

Single feeding travel(mm):500

Motor main output(kw): 4-6

Hydraulic(kw):1.5

Coolant pump(kw):0.09

Machine Size(LxWxH)(mm):3000*2200*1950

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness