How Cemented Carbide Enhances Industrial Cutting Applications

The use of cemented carbide cutting tools in industrial settings is widespread due to their strength and ability to operate under challenging conditions. These tools are engineered by sintering hard carbide grains with a metallic binder, resulting in a dense material that offers both wear resistance and thermal stability.

In practical terms, cemented carbide cutting tools allow for more consistent material removal across different metal grades. Whether used in turning operations or contour milling, the tool edge remains stable under high-speed conditions. This helps manufacturers maintain part quality and reduce production cycle times.

A significant advantage of cemented carbide is its resistance to edge breakdown. Even when cutting abrasive materials or working with interrupted cuts, these tools exhibit steady performance. As a result, they’re frequently selected for parts that require close tolerances and repeatability over large production volumes.

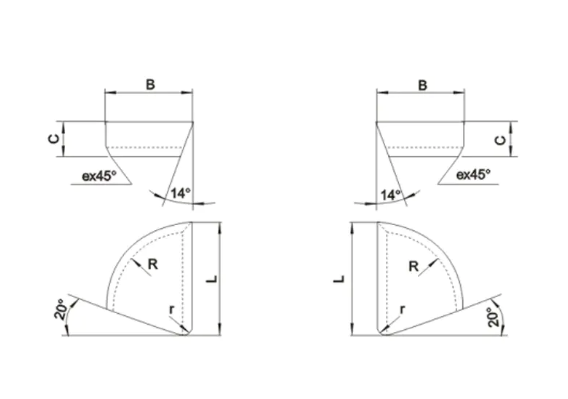

Cemented carbide tools are often manufactured with geometries that enhance chip control and surface finish. The strength of the material enables sharper edges and tighter radii, which improve performance in fine-detail operations. In many cases, applying a protective coating helps mitigate wear and prolong edge sharpness.

The availability of both solid carbide tools and insert-based solutions offers flexibility in application. Inserts can be indexed and replaced easily, making them suitable for continuous production. Solid tools, on the other hand, are often favored in smaller or more precise operations.

Cemented carbide also performs well in high-rigidity setups, such as those found in modern vertical and horizontal machining centers. When machine stability is paired with a durable tool, results include minimized vibration, reduced tool deflection, and improved consistency in surface profiles.

Ultimately, cemented carbide cutting tools contribute to productivity in machining environments where uptime, surface quality, and material throughput are all priorities. Their resilience, combined with the ability to be customized for specific materials or operations, keeps them relevant in evolving manufacturing workflows.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Inicio

- Literature

- Music

- Networking

- Otro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness