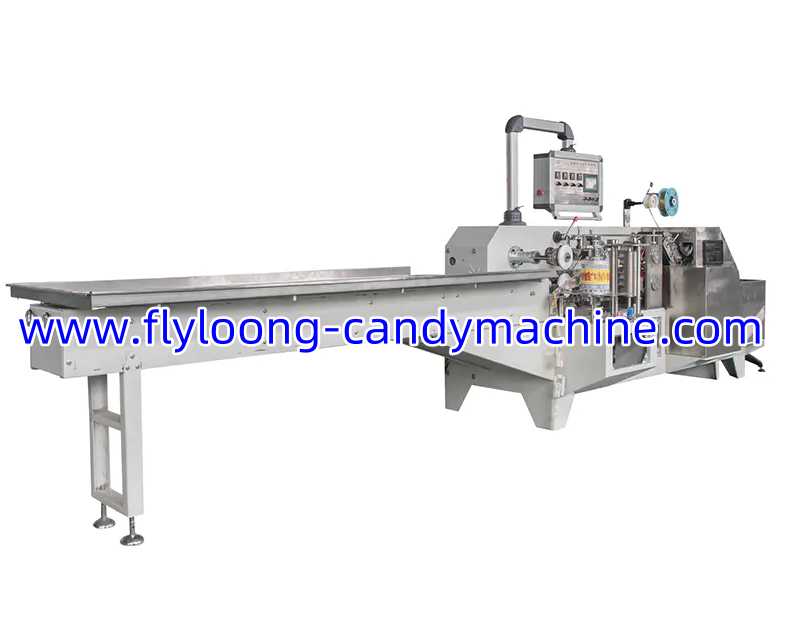

Automatic Rainbow Lollipop Machine in Action

The candy industry is undergoing a vivid transformation, thanks to innovations like the automatic rainbow lollipop machine, a cutting-edge solution redefining how confectionery is produced. At the heart of this colorful evolution stands flyloong-candymachine, a brand widely recognized for blending precision engineering with playful creativity.

Gone are the days of slow, labor-intensive lollipop production lines. Modern candy manufacturers now rely on automation to achieve consistency, efficiency, and scalable output. With the rise in demand for eye-catching, multi-colored sweets, the automatic rainbow lollipop machine has become a vital part of the production arsenal. This advanced machine handles everything—from syrup boiling and color blending to rope forming, shaping, and precise packaging.

What sets this system apart is its ability to synchronize mechanical precision with visual artistry. The vivid swirl patterns and layered hues characteristic of rainbow lollipops require flawless control of temperature, pressure, and timing. Automation ensures that each piece maintains uniform thickness, perfect spirals, and vibrant consistency batch after batch—something impossible to achieve manually on a large scale.

Incorporating features such as touch-screen controls, automated cleaning, and adaptable mold formats, the machine allows producers to quickly adjust sizes or shapes according to market trends. It minimizes material waste while maximizing production output, a must in today’s competitive market. Safety mechanisms and food-grade construction ensure compliance with international quality standards, which is essential for global distribution.

The appeal of rainbow lollipops is not limited to children; adults are equally drawn to nostalgic, high-quality treats that look as good as they taste. With a reliable automated line, candy brands can explore new flavor combinations, bold color patterns, and seasonal editions without disrupting production flow. This level of flexibility turns each batch into a marketable masterpiece.

For confectioners looking to stand out in a saturated industry, leveraging automation is no longer optional—it’s essential. By adopting the right technology, companies not only meet demand but exceed expectations in creativity and quality.

Want to see how vibrant candy dreams become automated reality? Visit https://www.flyloong-candymachine.com/product/candy-packing-machine/fldflat-lollipop-golden-wire-twist-packing-machine-20.html and take a bold bite into the future of sweet production.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness